Sheet Metal Flattening Machine

KINGREAL CEILING MACHINERY sheet metal flattening machine is a high-precision leveling equipment that can level various types of metal materials such as metal plates, metal mesh, metal parts and other shaped metal products.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About S

heet Metal Flattening Machine

Description Of Steel Plate Flattening Machine

KINGREAL CEILING MACHINERY sheet metal flattener can be used to process various metal materials with a thickness range of 15-60mm. It can not only effectively level metal sheets, but also is suitable for various forms of metal products such as metal bars, metal parts, hexagonal pipe bars, metal meshes, etc. Through advanced leveling technology, KINGREAL CEILING MACHINERY sheet metal flattener can significantly improve the flatness and surface quality of metal materials to meet the strict requirements of different application fields.

In addition, KINGREAL CEILING MACHINERY sheet metal flattener is easy to operate and maintain, and can be adjusted according to specific production needs to ensure an efficient production process.

Working Principle Of Sheet Metal Flattener

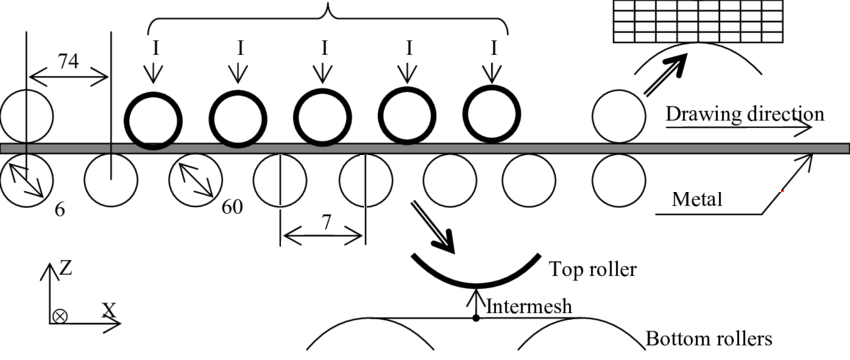

The working principle of the steel plate flattening machine is based on precise mechanical design and physical principles. It mainly achieves the leveling of metal sheets through the synergy of leveling rollers and auxiliary rollers. Specifically, the flexural force generated by the leveling rollers and auxiliary rollers during work is borne by the support wheels. This design ensures the stability and effectiveness of the leveling process.

During operation, multiple leveling rollers repeatedly bend the metal sheet by moving up and down. This repeated bending action redistributes the stress inside the material, thereby effectively eliminating the warping and unevenness of the material and achieving an ideal leveling effect.

The support rollers bear the bending force and transmit it to the surface of the leveling rollers through the auxiliary rollers. The auxiliary rollers are the same length as the working rollers but have a slightly smaller diameter. This design ensures that the metal sheet is evenly stressed along the entire width during the leveling process, avoiding the uneven pressure distribution that may be caused by direct contact between the support rollers and the leveling rollers, thereby effectively preventing the occurrence of indentation.

Highlight Of Sheet Metal Flattening Machine

※ Leveling Roller Box Convey Out Device

KINGREAL CEILING MACHINERY steel plate flattening machine adopts advanced Leveling Roller Box Convey Out Device. The support structure of the leveling roller and the shaft of the leveling roller are installed on a movable plate. The operator can easily remove the roller from the machine tool, which is convenient for comprehensive cleaning outside the machine tool.

The movable roller box design makes the installation and removal of the roller smoother. When the roller needs to be replaced or adjusted, the operation is convenient and there is no need for a complicated disassembly process.

Advantages Of Sheet Metal Flattener

(1) Good roller quality

KINGREAL CEILING MACHINERY steel plate flattening machine's leveling roller is made of high-quality smelting forging and processing high-grade alloy steel Gcr15, ensuring excellent performance and durability. This material has undergone a rigorous heat treatment process, and the roller body hardness reaches HRC28-32, which makes it show excellent leveling effect during the leveling process. High-quality rollers not only improve the working efficiency of the sheet metal flattener, but also greatly extend the service life of the sheet metal flattener, ensuring that users can still enjoy stable performance during long-term operation.

(2) High flatness accuracy

The flatness accuracy of the steel plate flattening machine can reach 0.1mm/m². This high level of flatness provides a solid foundation for the subsequent processing and utilization of metal sheets. The high-precision leveling effect effectively reduces the deformation and defects of the material, making the subsequent processing process smoother and greatly improving the quality of the final product.

(3) Anti-fouling and easy cleaning

The roller design of KINGREAL CEILING MACHINERY takes into account the cleaning needs in actual use and has excellent anti-fouling properties. The roller surface is specially treated to make it less likely to adhere to dirt and impurities, and users can clean it quickly and easily. This feature greatly improves the hygiene standards of the steel plate flattening machine.

Sheet Metal Flattener Frequently Asked Questions

What's the difference between four-high and six-high sheet metal flattening machine?

(1) Number of rollers and structure

- Four-high sheet metal flattening machine: It is composed of two upper rollers and two lower rollers, with a relatively simple structure, suitable for basic leveling needs.

- Six-high sheet metal flattening machine: It is composed of three upper rollers and three lower rollers, with additional support rollers. This structural design makes the pressure distribution more uniform and effectively improves the leveling effect.

(2) Leveling ability

- Four-high steel plate flattening machine: It is suitable for processing thinner plates or materials with lower stress requirements, and is suitable for light leveling work.

- Six-high steel plate flattening machine: It has strong leveling ability and can process plates with higher hardness and thicker thickness to meet more stringent production requirements.

(3) Pressure distribution

- Four-high sheet metal flattening machine: Due to the small number of rollers and concentrated pressure points, indentations or incomplete leveling may occur when processing thick plates.

- Six-high sheet metal flattening machine: The design of the support roller makes the pressure more evenly distributed, thereby reducing surface damage, improving the leveling quality, and ensuring the consistency of the processing effect.

How to choose a sheet metal flattener?

(1) Sheet thickness and material type

It is crucial to choose a steel plate flattening machine that is suitable for the sheet thickness and material type you want to process. Make sure the sheet metal flattening machine can meet your specific needs to achieve the best leveling effect.

(2) Leveling capacity

Choose a steel plate flattening machine with sufficient leveling capacity to adapt to your production volume and processing requirements. Insufficient leveling capacity may result in poor leveling results, which will affect subsequent processing.

(3) Number of rollers

The number of rollers directly affects the performance of the sheet metal flattener. More rollers usually mean more uniform pressure distribution and higher leveling quality, so the number and configuration of rollers should be considered when choosing.

(4) Automation level

Sheet metal flatteners can have manual, semi-automatic or fully automatic options. Choose the appropriate automation level according to actual production needs and budget to improve production efficiency and ease of operation.

(5) Brand and service

Choosing a trusted brand usually gives you higher quality assurance and after-sales service support. Make sure the manufacturer can provide timely technical support and maintenance services to reduce the impact of steel plate flattening machine failure on production.

Application Fields Of Sheet Metal Flattener

(1) Aerospace

Mainly used to process metal sheets for aircraft fuselages, wing surfaces and other key components. These components require extremely high flatness and precision to ensure good aerodynamic performance and structural strength during flight. The steel plate flattening machine can effectively eliminate the warping and deformation of the material and ensure the processing quality of the components.

(2) Construction industry

Widely used in the processing of metal building materials, such as steel beams, steel plates and steel structural parts. Through leveling, these materials can achieve better installation fit and load-bearing capacity, and improve the stability and safety of the building structure.

(3) Industry

Used for the production and processing of various metal parts and components. These parts may be used in mechanical equipment, transmission systems and industrial automation equipment.

(4) Shipbuilding industry

Used to process metal sheets for hulls and internal structures. These materials need to have good flatness and strength to withstand the challenges of the marine environment. The application of the sheet metal flattener can ensure the processing quality of ship components and improve the overall performance and safety of the ship.

(5) Automobile industry

Mainly used to process metal materials for car bodies, chassis and other important parts. These parts require high flatness and strength to ensure the safety and performance requirements of the car. The sheet metal flattener can effectively eliminate the deformation of the plate, ensure the matching accuracy of the car body and chassis, and thus improve the safety and comfort of the whole vehicle.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)