Metal Sheet Leveling Machine

Are you in search of a high-precision metal plate straightening machine capable of leveling coils with varying materials and thicknesses? Share your specifications with us, and KINGREAL CEILING MACHINERY will craft a tailored design solution just for you!

- KINGREAL CEILING MACHINERY

- CHINA

- 90 DAYS

- 9999

Details

Video About Metal Straightening Machine

Description Of Metal Sheet Straightener Machine

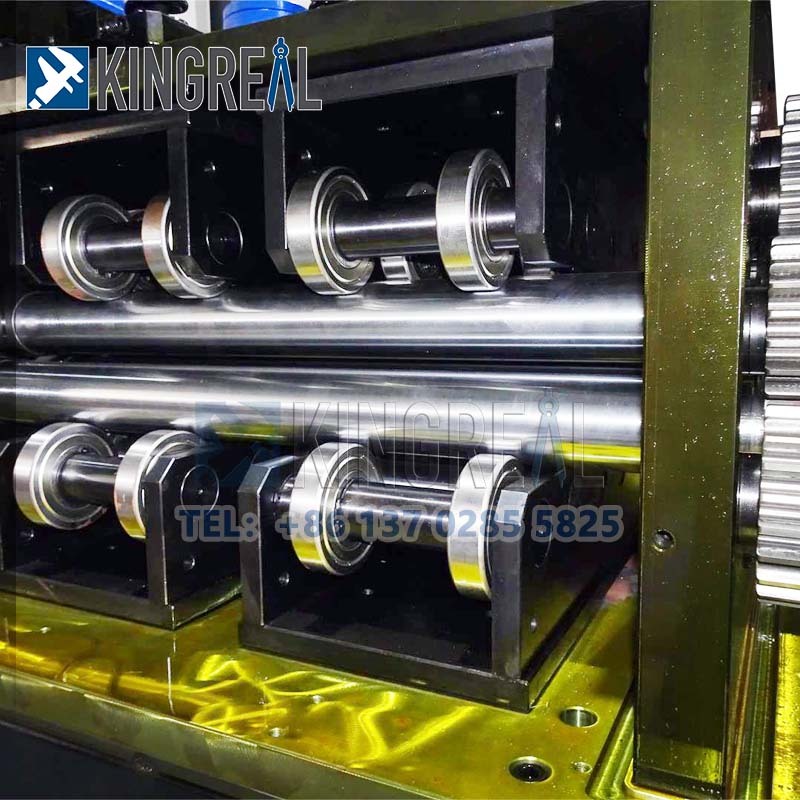

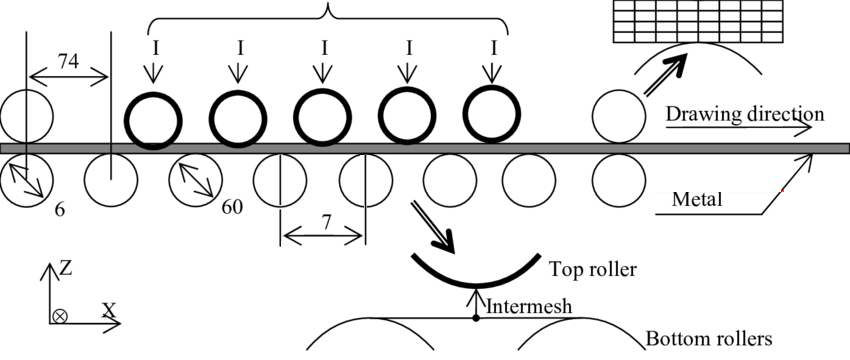

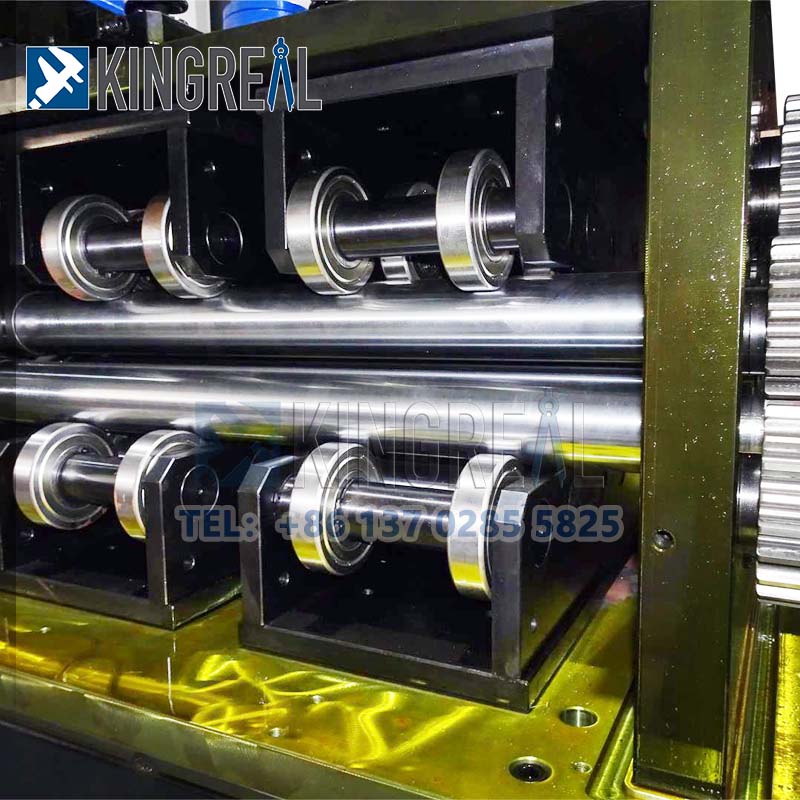

KINGREAL CEILING MACHINERY high precision metal sheet straightener machines are designed to level different types of raw materials, including different metal sheets and metal mesh, through the staggered arrangement and rotation of multiple sets of leveling rollers on rollers.

With the increasing demand of the metal processing industry, the requirements for the leveling process of raw materials also continue to provide, KINGREAL CEILING MACHINERY in order to meet the production needs of customers, can provide a variety of different leveling machine, including ordinary leveling machine, thick plate metal straightener machine and roller leveling machine.

KINGREAL CEILING MACHINERY will provide professional design and high quality production process if you need. Contact us now!

Technical Specification

Coil Width | 400-2200MM |

Roller Diameter | 60MM |

Coil Thickness | 6MM(max) |

Leveling Speed | 0-12M/Min |

Voltage | 380V 50HZ |

Applicable Object | Metal Processing |

Why Can Sheet Metal Be Levelled By a Plate Leveling Machine?

Uniform pressure:

By applying uniform pressure to the roller wheel of the metal straightening machine, plastic deformation of the metal sheet occurs between the roller wheels. This pressure is usually adjustable to accommodate different thicknesses and materials of the sheet metal.

Repeated bending:

During the leveling process, the sheet metal will undergo repeated bending and stretching as it passes through the roller. This repeated bending helps to release the stress inside the material, resulting in a more flat sheet.

Plastic deformation of material:

Metal materials will undergo plastic deformation under certain pressure and temperature. The plate straightening leveling machine takes advantage of this feature to achieve the desired flatness of the sheet when it passes through the roller.

Roller design:

Design factors such as the diameter, surface roughness and shape of the roller will affect the leveling effect. Properly designed rollers can effectively transfer pressure to ensure even leveling.

Featured About Sheet Leveler Machine

1. Excellent leveling precision: The machine achieves extremely high leveling precision because of the even force distribution on the leveling rollers, strong structural integrity, and minimal deformation.

2. Excellent surface quality: the plate has a smooth, high-quality surface following precise leveling.

3. Low noise and smooth transmission: The leveling machine operates smoothly thanks to a well-designed transmission system, which also lessens noise during operation.

Production Principles About Metal Straightener

1. Leveling rollers: By exerting pressure and bending on the plates, many sets of rollers are positioned in staggered rows to accomplish leveling. The drive system, which rotates the leveling rollers, is typically composed of a motor and a transmission mechanism.

2. Control system: A PLC control system can be employed to precisely modify the pressure and positioning of the leveling rollers to accommodate varying plate thicknesses and materials.

Different Application About Metal Sheet Leveler Machine

1. Perforated Panel Leveler Machine

Punching plate leveling machine is a kind of equipment specially used for leveling the plate after punching, which is mainly used to eliminate the unevenness of the plate caused by material deformation, warping or uneven stress during the punching process. The leveling machine repeatedly squeezes and stretches the plate through multiple sets of rollers to restore its flatness, which is widely used in punching production lines to ensure the accuracy and quality of the punched plate in the subsequent processes (e.g., bending, forming or welding).

2. Heavy Plate Leveling Machine

Heavy Plate Leveling Machine is a kind of equipment specially used for leveling thicker metal plates, which is widely used in the industries of iron and steel, shipbuilding, construction, and machinery manufacturing. As the thick plate is prone to bending, wave deformation or other deformation caused by stress during production and processing, the leveling machine corrects the thick plate through multiple sets of rollers to eliminate the residual stress in the material and achieve the leveling effect.

High Leveling Quality

KINGREAL CEILING MACHINERY's plate straightening leveling machines are excellent in sheet metal leveling, effectively eliminating warping, waves and bending deformation of sheet metal. Its advanced design and high-precision operation ensure the consistency of the leveling effect, so that the sheet can reach higher quality standards in subsequent processing.

In addition, the technical advantages of KINGREAL CEILING MACHINERY metal sheet straightening machines and the ability to adapt to different materials and thicknesses make KINGREAL CEILING MACHINERY plate leveling machines highly competitive in the market and favored by many customers. Through continuous technological innovation, KINGREAL CEILING MACHINERY is committed to providing customers with better finishing solutions to meet their production needs.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)