Products Lists

Suspended Ceiling Machine Solution

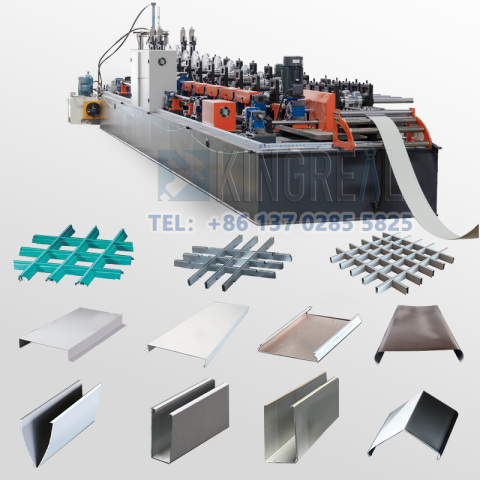

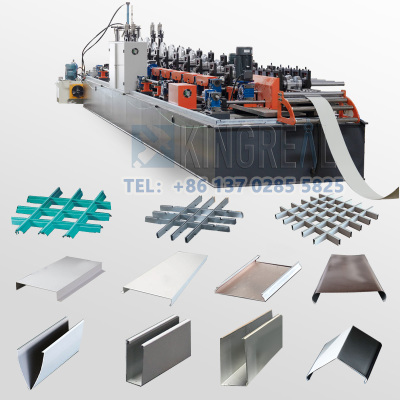

In the modern construction and decoration industry, customers' demands for materials are becoming increasingly diversified, especially in ceiling and wall decoration. In order to meet this market demand, KINGREAL CEILING MACHINERY provides a series of efficient and flexible forming equipment, including baffle ceiling machines, linear strip ceiling machines, open cell ceiling machines, hook on ceiling tile machines and wall panel cladding machines. In addition, for the cleaning needs of metal ceilings, KINGREAL CEILING MACHINERY also provides professional pallet layer pads washing and drying machine. These equipment can not only meet the high standards of the construction industry for beauty and functionality, but also adapt to the personalized needs of different customers.

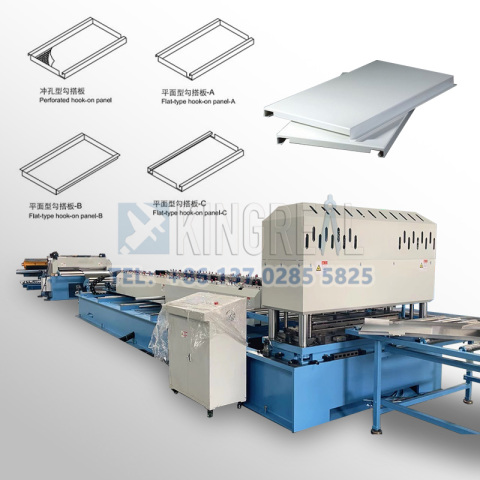

1. Hook on ceiling tile machine for ceiling decoration:

In the modern construction and decoration industry, ceiling decoration is not only a demand for beauty, but also a combination of functionality and practicality. As consumers' requirements for indoor environment continue to increase, hook on ceilings have gradually become a popular choice. As an important form of ceiling decoration, hook on ceilings are popular in the market for their unique design and excellent performance.

(1)Advantages of KINGREAL CEILING MACHINERY hook on ceiling tile machine

KINGREAL CEILING MACHINERY hook on ceiling tile machine is capable of producing a variety of hook on ceilings, including flat-type hook on ceilings and perforated hook on panels. The hook on ceiling tile machine supports the production of a variety of common sizes, such as 300x300mm, 300x600mm, 300x1200mm, 600x600mm, 600x1200mm, 800x800mm and 1000x1000mm. This flexibility allows customers to choose according to their specific needs.

The hook on ceiling tile machine consists of multiple precision components, including a decoiler, a straightener, a main roll forming machine, and a cut-to-length cutting and bending machine, etc. The power requirement of the equipment is 380V, 50Hz,3 Phases and the power consumption is 30Kw. The roll forming machine is computer-controlled. Customers only need to adjust the parameters in the system, and the roller group will automatically adjust the width and narrowness to produce the hook on ceiling of the required size.

This efficient automated production not only improves production efficiency, but also ensures product consistency and quality. For customers who need mass production, the hook on ceiling tile machine is undoubtedly an ideal choice.

(2) Features of hook on ceilings

Hook on ceilings are widely used in ceiling systems. They are simple and elegant, easy to install, and light-shielding and windproof. This type of hook on ceiling adopts a unified hook-up structure, usually with the same panel size, and is installed through a keel.

2. Wall panel forming machine for wall decoration:

In modern buildings, wall decoration is not only for beauty, but also an important factor in improving the functionality and comfort of the space. As people's requirements for indoor environmental quality continue to increase, wall panels, as an ideal wall decoration material, are gradually favored.

(1)Advantages of KINGREAL CEILING MACHINERY metal wall cladding panel machine

KINGREAL CEILING MACHINERY wall panel cladding machine is specially designed to produce various types of wall panels, including flat panels, small V-ribs, large V-ribs, small pencil ribs and large pencil ribs. The equipment can realize continuous unwinding, feeding, punching, forming and cutting to length. The whole production line adopts PLC control system and supports fully automatic operation, which greatly improves production efficiency and accuracy.

According to the specific technical requirements of customers, the metal wall cladding panel machine can be customized to meet the needs of different markets and customers. Customers can choose different types of wall panels according to the requirements of the project to ensure the diversity and adaptability of the products.

The design of the wall panel cladding machine makes it easy to operate and maintain, which can effectively reduce production costs. For customers who need efficient production, choosing KINGREAL CEILING MACHINERY will be a wise decision.

(2) Characteristics of wall panels

Wall panels are a very popular decorative material in modern buildings and are widely used in commercial and public buildings. Its main advantages are beauty, durability and good sound insulation. Wall panels can not only enhance the overall sense of space, but also effectively isolate noise and create a more comfortable working and living environment.

3. Pallet layer pads washing and drying machine for cleaning

Advantages of KINGREAL CEILING MACHINERY metal sheet cleaning machine

The pallet layer pads washing and drying machine provided by KINGREAL CEILING MACHINERY can efficiently clean various metal materials, including galvanized sheets, stainless steel sheets, mirror stainless steel sheets, aluminum sheets, ceilings and even plastic sheets. The equipment can remove oil and dirt to ensure that the materials are in the best condition before use.

The pallet layer pads washing and drying machine consists of a cleaning part and a drying part. The cleaning part includes a brush, a water tank, a drain pipe, etc., and the drying part consists of a drying furnace. Under normal circumstances, the board washing speed can reach 7m/min. If the customer has higher requirements for the board washing speed, KINGREAL CEILING MACHINERY can also provide customized services to meet specific production needs.

4.Metal powder spray coating line

Metal powder coating production line can spray various types and sizes of metal objects to extend the service life of the product.

Benefits of KINGREAL CEILING MACHINERY metal powder spray coating line

(1)Efficiently cured metal powder coating production line

KINGREAL CEILING MACHINERY metal powder spray coating line uses cutting-edge curing technique to rapidly and uniformly cure the sprayed powder. Along with boosting production efficiency, this guarantees the coating's stability and durability. The metal powder coating production line can fulfill customer demands for large-scale production by means of an improved heat treatment process, so completing curing in a relatively short time.

(2)Adaptable metal powder spray coating line

KINGREAL CEILING MACHINERY metal powder coating production line can cover metal items of several sizes and forms. Notwithstanding the size, the metal powder spray coating line can provide exact spraying to satisfy various consumer personalization requirements. Additionally noteworthy is the ability of the KINGREAL CEILING MACHINERY metal powder coating production line to rapidly change settings to fit various materials and spray demands.

(3)Effective metal powder spray coating line ab environmentally friendly nature

KINGREAL CEILING MACHINERY metal powder coating production line's powder coating is more environmentally friendly than conventional coating techniques, less environmentally damaging, and meets modern industry sustainable development demands.

Attributes of metal powder spray

(1)Line for spraying metal powder with great adhesion

Good adhesion between powder and metal surface will be guaranteed by KINGREAL CEILING MACHINERY metal powder spray coating line. The metal powder coating production line can really avoid coating peeling or blistering by exactly controlling the nozzle distance and spraying pressure, hence guaranteeing wear resistance and corrosion resistance in prolonged usage.

(2)Metal powder spray coating line maximizing powder use

Optimal powder utilization, waste reduction, and cost-cutting for production are all possible with KINGREAL CEILING MACHINERY metal powder coating production line. To guarantee that every gram of powder can have its full impact, a recycling system collects and reuses the unattached powder throughout the spraying operation.

(3)Metal powder spray coating line with custom color choosing

KINGREAL CEILING MACHINERY metal powder coating production line allows for several color combinations. This customized color choice can satisfy consumer demand.

In the modern construction and decoration industry, customers' demands for materials are becoming increasingly diversified, especially in ceiling and wall decoration. In order to meet this market demand, KINGREAL CEILING MACHINERY provides a series of efficient and flexible forming equipment, including baffle ceiling machines, linear strip ceiling machines, open cell ceiling machines, hook on ceiling tile machines and wall panel cladding machines. In addition, for the cleaning needs of metal ceilings, KINGREAL CEILING MACHINERY also provides professional pallet layer pads washing and drying machine. These equipment can not only meet the high standards of the construction industry for beauty and functionality, but also adapt to the personalized needs of different customers.

1. Hook on ceiling tile machine for ceiling decoration:

In the modern construction and decoration industry, ceiling decoration is not only a demand for beauty, but also a combination of functionality and practicality. As consumers' requirements for indoor environment continue to increase, hook on ceilings have gradually become a popular choice. As an important form of ceiling decoration, hook on ceilings are popular in the market for their unique design and excellent performance.

(1)Advantages of KINGREAL CEILING MACHINERY hook on ceiling tile machine

KINGREAL CEILING MACHINERY hook on ceiling tile machine is capable of producing a variety of hook on ceilings, including flat-type hook on ceilings and perforated hook on panels. The hook on ceiling tile machine supports the production of a variety of common sizes, such as 300x300mm, 300x600mm, 300x1200mm, 600x600mm, 600x1200mm, 800x800mm and 1000x1000mm. This flexibility allows customers to choose according to their specific needs.

The hook on ceiling tile machine consists of multiple precision components, including a decoiler, a straightener, a main roll forming machine, and a cut-to-length cutting and bending machine, etc. The power requirement of the equipment is 380V, 50Hz,3 Phases and the power consumption is 30Kw. The roll forming machine is computer-controlled. Customers only need to adjust the parameters in the system, and the roller group will automatically adjust the width and narrowness to produce the hook on ceiling of the required size.

This efficient automated production not only improves production efficiency, but also ensures product consistency and quality. For customers who need mass production, the hook on ceiling tile machine is undoubtedly an ideal choice.

(2) Features of hook on ceilings

Hook on ceilings are widely used in ceiling systems. They are simple and elegant, easy to install, and light-shielding and windproof. This type of hook on ceiling adopts a unified hook-up structure, usually with the same panel size, and is installed through a keel.

2. Wall panel forming machine for wall decoration:

In modern buildings, wall decoration is not only for beauty, but also an important factor in improving the functionality and comfort of the space. As people's requirements for indoor environmental quality continue to increase, wall panels, as an ideal wall decoration material, are gradually favored.

(1)Advantages of KINGREAL CEILING MACHINERY metal wall cladding panel machine

KINGREAL CEILING MACHINERY wall panel cladding machine is specially designed to produce various types of wall panels, including flat panels, small V-ribs, large V-ribs, small pencil ribs and large pencil ribs. The equipment can realize continuous unwinding, feeding, punching, forming and cutting to length. The whole production line adopts PLC control system and supports fully automatic operation, which greatly improves production efficiency and accuracy.

According to the specific technical requirements of customers, the metal wall cladding panel machine can be customized to meet the needs of different markets and customers. Customers can choose different types of wall panels according to the requirements of the project to ensure the diversity and adaptability of the products.

The design of the wall panel cladding machine makes it easy to operate and maintain, which can effectively reduce production costs. For customers who need efficient production, choosing KINGREAL CEILING MACHINERY will be a wise decision.

(2) Characteristics of wall panels

Wall panels are a very popular decorative material in modern buildings and are widely used in commercial and public buildings. Its main advantages are beauty, durability and good sound insulation. Wall panels can not only enhance the overall sense of space, but also effectively isolate noise and create a more comfortable working and living environment.

3. Pallet layer pads washing and drying machine for cleaning

Advantages of KINGREAL CEILING MACHINERY metal sheet cleaning machine

The pallet layer pads washing and drying machine provided by KINGREAL CEILING MACHINERY can efficiently clean various metal materials, including galvanized sheets, stainless steel sheets, mirror stainless steel sheets, aluminum sheets, ceilings and even plastic sheets. The equipment can remove oil and dirt to ensure that the materials are in the best condition before use.

The pallet layer pads washing and drying machine consists of a cleaning part and a drying part. The cleaning part includes a brush, a water tank, a drain pipe, etc., and the drying part consists of a drying furnace. Under normal circumstances, the board washing speed can reach 7m/min. If the customer has higher requirements for the board washing speed, KINGREAL CEILING MACHINERY can also provide customized services to meet specific production needs.

4.Metal powder spray coating line

Metal powder coating production line can spray various types and sizes of metal objects to extend the service life of the product.

Benefits of KINGREAL CEILING MACHINERY metal powder spray coating line

(1)Efficiently cured metal powder coating production line

KINGREAL CEILING MACHINERY metal powder spray coating line uses cutting-edge curing technique to rapidly and uniformly cure the sprayed powder. Along with boosting production efficiency, this guarantees the coating's stability and durability. The metal powder coating production line can fulfill customer demands for large-scale production by means of an improved heat treatment process, so completing curing in a relatively short time.

(2)Adaptable metal powder spray coating line

KINGREAL CEILING MACHINERY metal powder coating production line can cover metal items of several sizes and forms. Notwithstanding the size, the metal powder spray coating line can provide exact spraying to satisfy various consumer personalization requirements. Additionally noteworthy is the ability of the KINGREAL CEILING MACHINERY metal powder coating production line to rapidly change settings to fit various materials and spray demands.

(3)Effective metal powder spray coating line ab environmentally friendly nature

KINGREAL CEILING MACHINERY metal powder coating production line's powder coating is more environmentally friendly than conventional coating techniques, less environmentally damaging, and meets modern industry sustainable development demands.

Attributes of metal powder spray

(1)Line for spraying metal powder with great adhesion

Good adhesion between powder and metal surface will be guaranteed by KINGREAL CEILING MACHINERY metal powder spray coating line. The metal powder coating production line can really avoid coating peeling or blistering by exactly controlling the nozzle distance and spraying pressure, hence guaranteeing wear resistance and corrosion resistance in prolonged usage.

(2)Metal powder spray coating line maximizing powder use

Optimal powder utilization, waste reduction, and cost-cutting for production are all possible with KINGREAL CEILING MACHINERY metal powder coating production line. To guarantee that every gram of powder can have its full impact, a recycling system collects and reuses the unattached powder throughout the spraying operation.

(3)Metal powder spray coating line with custom color choosing

KINGREAL CEILING MACHINERY metal powder coating production line allows for several color combinations. This customized color choice can satisfy consumer demand.

Get the latest price? We'll respond as soon as possible(within 12 hours)