- Home

- >

- Products

- >

- NC Servo Feeder

- >

NC Servo Feeder

KINGREAL CEILING MACHINERY can provide customers with a variety of NC Servo Feeders suitable for metal coils of different widths and thicknesses to meet various production needs. Ensure efficiency and precision in every production link.

- KINGREAL CEILING MACHINERY

- China

- 30 Days

- 9999

Details

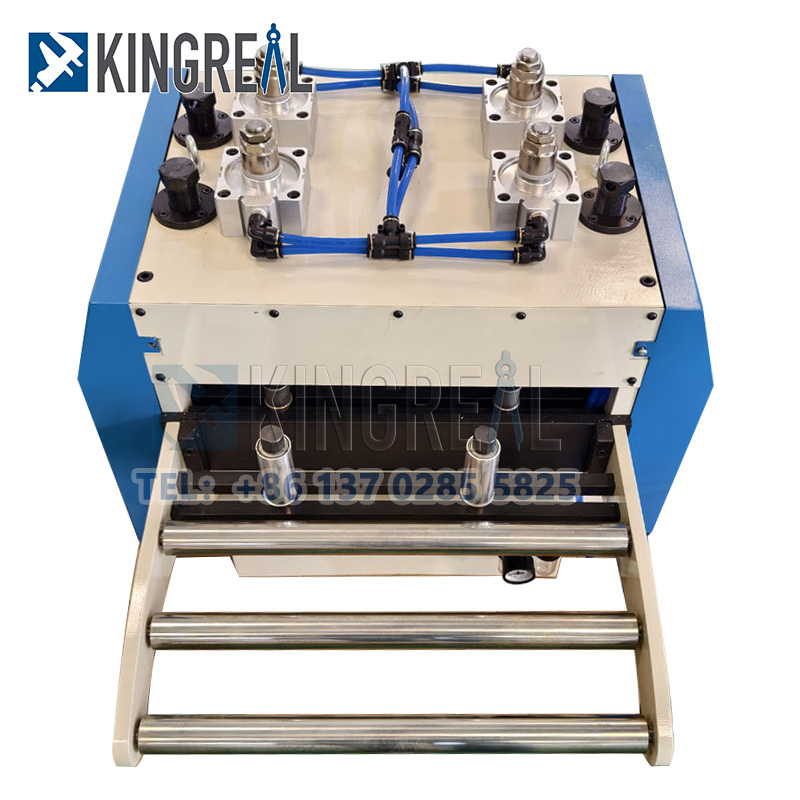

Brief Profile of NC Servo Feeder

KINGREAL CEILING MACHINERY servo feeder system is an advanced feeding equipment designed for accurately feeding metal materials into machines for stamping, cutting or forming. Compared with traditional mechanical or pneumatic feeders, NC servo roll feeders are equipped with high-performance servo motors that can achieve excellent speed, position and acceleration control. The application of this technology has enabled servo feeders to reach unprecedented heights in both precision and efficiency, becoming an indispensable part of the field of manufacturing automation.

By integrating servo feeder system, various industries can significantly increase their production capacity. These devices can not only quickly adapt to various material types and specifications, but also minimize material waste and increase overall production. Whether in the automotive, home appliances, electronics or metal processing industries, KINGREAL CEILING MACHINERY NC Servo Feeders have demonstrated their superior performance.

Main Parameters of Servo Feeder System

| Material width (mm) | 1500 |

| Feeding capacity (mm) | 1.2x1500 3.2x300 |

| Feeding length (mm) | 0-9999.99 |

| Feeding speed (m/min) | 16 |

| Relaxation method | Pneumatic release (standard)/mechanical release (optional) |

| Feeding direction | Left←→right |

| Power supply voltage(v) | AC 3phase 220V/380V |

| Machine weight(kg) | 360 |

Characteristic of NC Servo Roll Feeder

Add a guide stainless steel plate to make feeding more stable |

The body is made of electrostatic spraying, which has good adhesion and strong corrosion resistance |

The top cover is made of 15mm smooth plate |

The feed port and the discharge port are equipped with lifting blocking wheels |

The feed support roller is a seamless steel tube plated with hard chrome, which is durable and anti-collision |

The aluminum alloy enlarges the synchronous pulley, hollows out and reduces weight, reduces inertia, and improves feeding accuracy |

The feed roller is precisely ground and thickened with chrome plating |

The bearings are imported from Japan NTN bearings |

The thickness of the main wall panels on both sides is 20mm |

The gears are fully ground with high-precision gears |

Advantages of Servo Feeder System

1. High precision

A significant advantage of the NC servo roll feeder is its excellent material positioning and alignment accuracy. The NC servo feeder of KINGREAL CEILING MACHINERY uses an advanced computer-controlled servo system to achieve a variety of numerical controls that were previously impossible, ensuring that each piece of material can be processed in the correct position.

This high precision is not only reflected in the accuracy of feeding, but also in its ability to quickly adapt to changes in material thickness and width. Whether processing thin or thick plates, the NC servo feeder can maintain stable accuracy, allowing the production line to quickly switch between different materials, significantly improving the flexibility and efficiency of production. In addition, precise feeding control also reduces material waste and reduces production costs for customers.

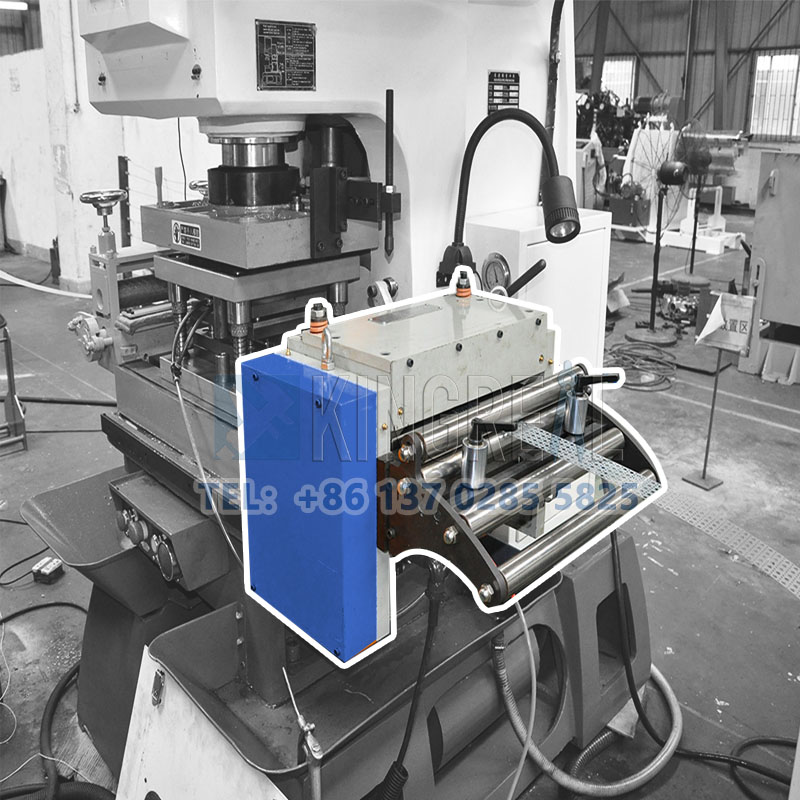

2. Wide applicability

KINGREAL CEILING MACHINERY NC servo roll feeder or servo feeder system is designed to adapt to a variety of materials and sizes, and can meet a variety of production needs. This makes it particularly suitable for handling the feeding of thin, medium and thick plates, and can meet the needs of different customers. For example, in the metal processing industry, it is often necessary to handle metal coils of various specifications, and the flexibility of the servo feeder system enables companies to easily meet this challenge. And the NC servo roll feeder can be used well with the punch press machine.

This versatility makes the NC Servo Feeder not only suitable for specific industries, but also can be applied across industries, thereby improving the return on investment. Companies no longer need to invest in different types of feeding equipment for different materials, reducing the overall equipment procurement and maintenance costs.

3. Flexible feeding step

Servo feeder systems or NC servo roll feeder support feeding step distances of 0-10 meters and provide multi-stage feeding, which greatly enhances their flexibility. Whether in short-distance feeding or long-distance feeding, the equipment can be quickly adjusted according to production needs. This flexibility allows the production line to operate more efficiently, especially when frequent switching of production tasks is required, and KINGREAL CEILING MACHINERY NC servo roll feeders show their unique advantages.

In addition, flexible feeding step distances also allow the machine to adapt to different production rhythms and meet various needs from small batches to large batches. Whether it is mass production or customized production, the servo feeder system can respond quickly to ensure the smooth implementation of production plans.

4. High-speed operation

KINGREAL CEILING MACHINERY servo feeder system or NC servo roll feedercan be quickly configured to adapt to different operations with its programmable settings and user-friendly interface. This allows operators to complete the machine settings in a short time, significantly reducing downtime between production runs.

The touch screen operation interface is simple and clear, and operators can quickly get started without long training. This ease of use not only improves operational efficiency, but also reduces the incidence of human errors, further ensuring the smooth progress of production. At the same time, through real-time monitoring and feedback systems, operators can keep track of the machine's operating status at any time to ensure that the equipment operates in the best condition.

5. Improve production efficiency

By optimizing the feeding speed and minimizing manual adjustments, the NC Servo Feeder can significantly increase the throughput of the production line. The improvement in production efficiency is not only reflected in higher output, but also in shorter delivery cycles and lower production costs. Enterprises are able to complete more production tasks in a shorter time, thereby improving market competitiveness.

Ways of Extend the Life of Servo Feeder System

In order to ensure the long-term and stable operation of the KINGREAL CEILING MACHINERY NC servo roll feeder, regular maintenance and inspection are essential. Here are some maintenance suggestions of NC servo roll feeder:

1. Regular cleaning: Keeping the NC servo roll feeder clean and free of debris is the basis for ensuring the normal operation of the servo feeder system. Dirt and dust can cause wear and reduce feeding accuracy, so rollers, clamps and other components should be checked and cleaned regularly.

2. Lubrication and maintenance: Proper lubrication of the moving parts of the feeder is essential for smooth operation and reduced wear. It is recommended to follow the manufacturer's recommendations on lubrication intervals and lubricant types to ensure that the various moving parts are always in optimal condition.

3. Drive system inspection: Regularly check the servo feeder system or NC servo roll feeder, and controller for signs of wear or damage. Make sure all connections are secure and that the NC servo roll feeder and drive are operating properly to avoid production stoppages due to failures.

4. Software update: Regularly check the control software of the NC Servo Feeder to ensure that it is the latest version to take advantage of the latest features and performance optimizations.

5. Operation training: Provide adequate training for operators to familiarize them with the operation and maintenance knowledge of the servo feeder system, ensure that best operating practices are followed during use, and thus reduce the occurrence of human failures.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)