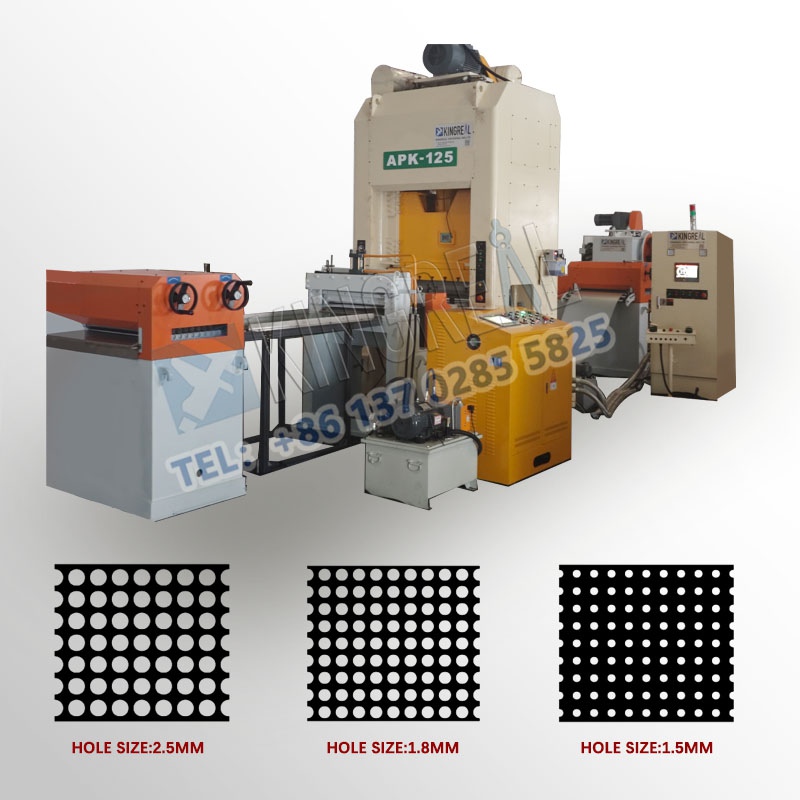

Metal Sheet Perforated Machine

KINGREAL CEILING MACHINERY can provide customized metal sheet perforated machine manufacturing solutions according to customer needs, and KINGREAL CEILING MACHINERY can provide different types of machines to meet customers' different applications for perforated sheets.

- KINGREAL CEILING MACHINERY

- CHINA

- 90 Days

- 9999

Details

Video About Metal Sheet Perforated Machine

Definition Of Sheet Metal Perforation Line

The perforated sheet making machine is a device specially used to process metal sheets of different materials into the required hole type, and is usually used to manufacture various metal perforated sheets. The diversity of these hole type designs meets different industrial needs. Common hole types include round staggered holes, round straight holes, hexagon staggered holes, square straight holes, and round end slot staggered holes. The design of these hole types not only affects the appearance of the product, but is also directly related to its functionality and application effect.

During the punching process, the metal sheet is precisely punched through the perforated sheet making machine to form holes of specific shapes and sizes. This process not only improves the permeability, strength and aesthetics of the material, but also lays the foundation for subsequent secondary processing. Through the punching process, the weight of the metal sheet is reduced while maintaining the stability of the structure, making it have excellent performance in many application scenarios.

After punching, metal sheets are usually used by various industries for further secondary processing to form the final finished product. These perforated sheets are widely used in many fields such as architectural decoration, industrial equipment, food processing, chemical pharmaceuticals, environmental protection energy, etc.

The wide application of perforated sheet making machines makes metal perforated sheets play a vital role in many industries. Its diverse hole design and efficient processing capabilities make it an important tool to meet the needs of modern manufacturing.

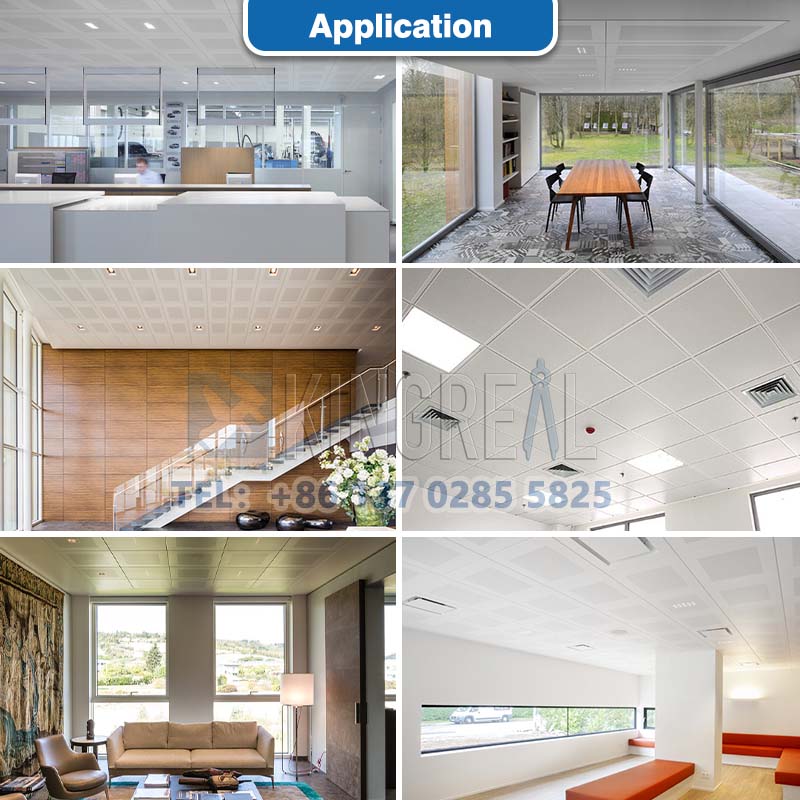

Application Of Sheet Metal Perforation Line

As a key equipment for metal material processing, perforated sheet making machines are widely used in many industries such as construction, industry and chemical industry, and are valued for their efficiency and precision in manufacturing metal perforated sheets. In modern manufacturing, metal perforated sheets, as an important basic material, are widely used in fields such as structural parts, filters, ventilation equipment and decorative materials. With the continuous advancement of industry technology, many industries have increasingly higher requirements for the quality and precision of perforated sheets, especially in terms of aperture size accuracy and hole edge quality. These requirements not only affect the overall performance and aesthetics of the product, but may also have a profound impact on subsequent processing and use effects.

In order to meet these changing market needs, KINGREAL CEILING MACHINERY perforated sheet making machines continue to work hard on technological innovation and professional level. By introducing advanced punching technology and high-precision control systems, the production process is continuously optimized to ensure that each punched sheet can meet industry standards and customer's personalized needs.

Different Types Of Sheet Metal Perforation Lines

According to the subsequent secondary processing applications of punched sheets in different industries, KINGREAL CEILING MACHINERY provides three types of perforated sheet making machines: sheet metal perforation line with cutting, metal sheet perforated machine with rewinding and metal ceiling perforation line.

By replacing the punching die, KINGREALCEILING MACHINERY 's perforated sheet making machine can flexibly produce metal sheets with different hole diameters and hole shapes without the need for cumbersome equipment replacement or re-commissioning. This efficient operation method not only saves equipment investment costs, but also greatly shortens production preparation time.

● Sheet metal perforation line with cutting

The metal sheet perforated machine with cutting is specially used to cut metal sheets according to the specific needs of customers after punching. Through this process, standardized punched sheets are finally formed, which is convenient for subsequent processing and use.

★ Workflow : Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Shearing Machine

★ Featured components of sheet metal perforation line with cutting

Cutting station:

KINGREAL CEILING MACHINERY's cutting station uses blades made of high-hardness materials to ensure the flatness of the cut surface of the sheet after shearing. This design not only improves the quality of shearing, but also extends the service life of the blade. In addition, the cutting station is controlled by highly intelligent equipment to ensure that the actual length of the shearing is consistent with the preset length, avoiding the problem of unevenness caused by operating errors.

★ Application areas

The perforated plates processed by the metal sheet perforated machine with cutting are usually used in the manufacture of a variety of products, such as chairs, wall panels, balcony guardrails, screens, stairs, baskets, washing baskets, grills, reactors, etc. These finished products play an important role in architectural decoration, furniture manufacturing and industrial equipment.

● Perforated sheet making machine with rewinding

The sheet metal perforation line with rewinding is to wind the metal plate through the recoiler after punching. This process not only facilitates subsequent transportation and storage, but also optimizes the subsequent manufacturing process.

★ Workflow: Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Hydraulic Recoiler

★ Featured components of metal sheet perforated machine with rewinding

(1)Metal sheet washing machine:

KINGREAL CEILING MACHINERY has innovatively added a metal sheet washing machine to the sheet metal perforation line with rewinding. After the previous punching process, the metal plate may leave stains on the surface. The metal sheet washing machine can effectively clean these stains and provide a clean surface for subsequent processing. This design saves time for subsequent processing and improves production efficiency.

(2)Recoiler:

The recoiler is one of the core equipment in the metal sheet perforated machine with rewinding. It is designed to improve the processing efficiency and storage convenience of punched metal sheets. By neatly rolling up the punched metal sheets, the recoiler not only optimizes the space utilization, but also provides great convenience for subsequent transportation and processing.

★ Application areas

The punched plates processed by the perforated sheet making machine with rewinding are usually used to manufacture filter elements, bread trays, ventilation and heat dissipation panels, filters, screens, separators, wind power equipment protective covers, solar panel brackets, etc. These products have a wide range of applications in industries such as environmental protection, energy and food processing.

● Metal ceiling perforation line

The metal ceiling perforation line is a device designed to meet specific architectural decoration needs. It can be used in conjunction with KINGREAL CEILING MACHINERY's metal ceiling machine to produce different sizes and types of perforated ceilings, such as the common sizes of 30x30cm, 60x60cm and 60x120cm, as well as different types such as clip in, lay in, tegular, etc.

★ Workflow: Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press

★ Featured Components of Metal ceiling perforation line

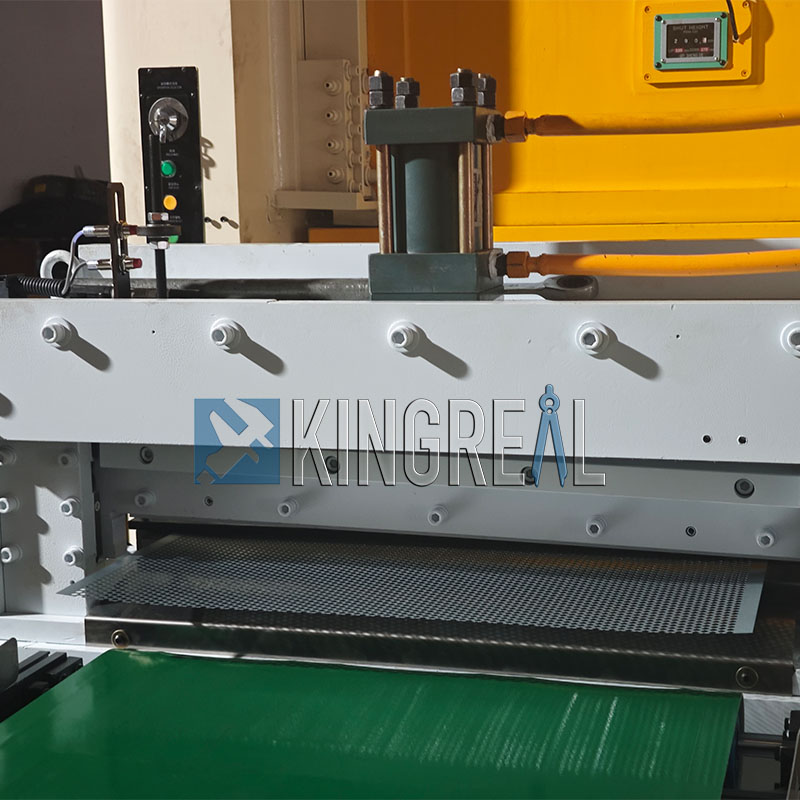

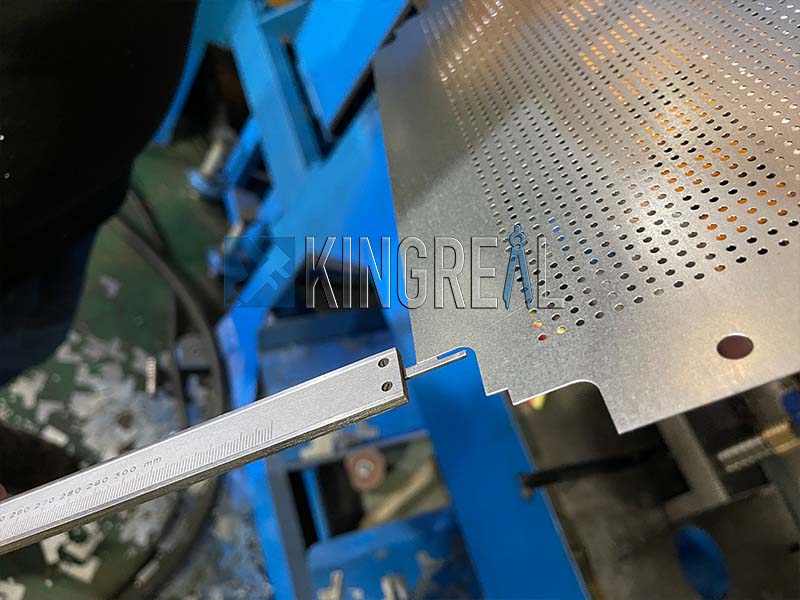

Notching and Press :

After punching, the metal sheet will be fed into the Notching and Press Machine. This equipment can cut the four corners of the sheet and make a preliminary cut to form the prototype of the ceiling. This process not only improves production efficiency, but also ensures that the edges of the ceiling are flat, which is convenient for subsequent installation and use.

★ Application areas

The perforated ceiling has a beautiful appearance and good decorative effect. In addition, due to the presence of many small holes, sound can pass through, weakening the intensity of the sound and appropriately reducing the noise.

Features Of Metal Sheet Perforated Machine

Precision leveler

KINGREAL CEILING MACHINERY's perforated sheet making machine is equipped with a high-performance precision leveler, which consists of 4 upper wheels and 5 lower wheels to form a professional 9-roller flattening device. The core purpose of this design is to effectively level the metal coil to ensure that its surface is smooth and free of ripples. Through the multi-round flattening process, the metal material can be fully shaped before entering the punching stage, which is crucial to improving the punching accuracy.

The efficient operation of the leveler not only removes the bending and deformation of the coil during storage and transportation, but also significantly reduces the errors generated in the subsequent punching process. This high-precision leveling process makes the punched product more consistent in size and shape, reduces the scrap rate caused by uneven materials, and thus improves the customer's production efficiency and the market competitiveness of the final product.

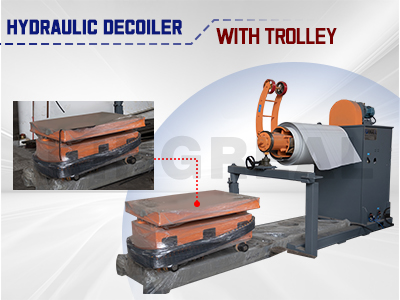

Decoiler with feeding trolley

In order to further improve the automation of the sheet metal perforation line, KINGREAL CEILING MACHINERY equipped the decoiler with a feeding trolley. This innovative design makes the handling process of metal coils more efficient and convenient. Customers only need to place the metal coil on the feeding trolley, and the system will automatically transport the coil to the decoiler to complete the subsequent unwinding and punching operations.

The introduction of this automatic feeding system significantly saves labor costs and reduces the workload of operators. At the same time, it can also maximize time utilization and ensure the continuity and smoothness of the production process. By reducing manual intervention, KINGREAL CEILING MACHINERY's sheet metal perforation line reduces the possibility of human errors during operation, making the overall production process more stable and reliable.

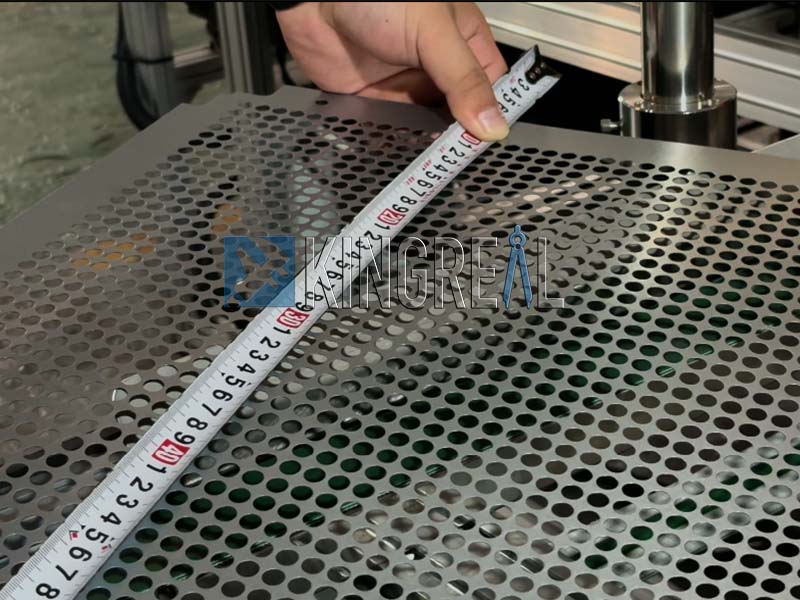

Quality Inspection

The products produced by KINGREAL CEILING MACHINERY's perforated sheet making machine absolutely meet the production needs of customers, with high precision, no burrs on the surface, and consistent hole size. Therefore, good quality products can be better put into secondary processing and manufacturing. This is also the most feedback from customers for KINGREAL CEILING MACHINERY's sheet metal perforation line.

What Can KINGREAL CEILING MACHINERY Provide?

(1) Customized solutions

KINGREAL Ceiling Machinery focuses on providing customers with highly customized sheet metal perforation line manufacturing solutions designed to meet the specific needs of different industries and customers. As the market continues to develop, customers have higher requirements for the performance and flexibility of perforated sheet making machine. In order to help customers stand out in a highly competitive environment, KINGREAL Ceiling Machinery is committed to providing tailor-made solutions to ensure that each sheet metal perforation line can perfectly match the actual production needs of customers.

Throughout the customization process, KINGREAL Ceiling Machinery's professional engineering team will communicate in depth with customers to understand their production processes, product specifications and market needs in detail. Based on the drawings and specific requirements provided by customers, the team will conduct comprehensive analysis and discussion to develop the most appropriate production plan.

(2) High-quality metal sheet perforated machine

During the manufacturing process of the perforated sheet making machine, KINGREAL CEILING MACHINERY always adheres to high standards of quality control. Starting from the selection of raw materials, KINGREAL CEILING MACHINERY has implemented a strict inspection process and only uses high-quality materials to ensure the durability and reliability of the sheet metal perforation line. During the manufacturing process, KINGREAL CEILING MACHINERY has a professional technical team to supervise the whole process to ensure that every metal sheet perforated machine sent to the customer's factory meets industry standards and customer expectations.

This strict control of quality has made KINGREAL CEILING MACHINERY's sheet metal perforation lines widely praised in the market. Customers have said that KINGREAL CEILING MACHINERY's equipment has a high return on investment, low maintenance costs, and extremely strong durability of the machine. This high-quality perforated sheet making machine enables customers to maintain efficient production capacity during long-term use, thereby achieving the best balance between cost and benefit.

(3)After-sales service

KINGREAL CEILING MACHINERY after-sales team is composed of a group of strictly trained professionals who not only have solid technical knowledge but also have rich field experience. Whether it is equipment commissioning, troubleshooting, or daily maintenance, they can handle it with an efficient and professional attitude. When the perforated sheet making machine encounters a fault, the after-sales team can find the problem as quickly as possible and conduct a detailed analysis to ensure that the normal operation of the equipment is restored in the shortest time. Through quick response, KINGREAL CEILING MACHINERY helps customers minimize downtime and ensure the continuity and stability of the sheet metal perforation line.

How To Get Sheet Metal Perforation Line Solutions?

Please send your production requirements to KINGREAL CEILING MACHINERY, and we will have professional staff to contact you to start customization!

1. Coil thickness

2. Coil width

3.Coil material

4.Punching design

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)