Coil Perforation Line Shipped to Bangladesh

1. Coil Perforation Line sent to Bangladesh

Last week, KINGREAL CEILING MACHINERY's perforated punching machine was sent to a customer factory in Bangladesh.

The perforated punching machine was strictly tested by KINGREAL CEILING MACHINERY engineers and was judged to be a qualified machine.

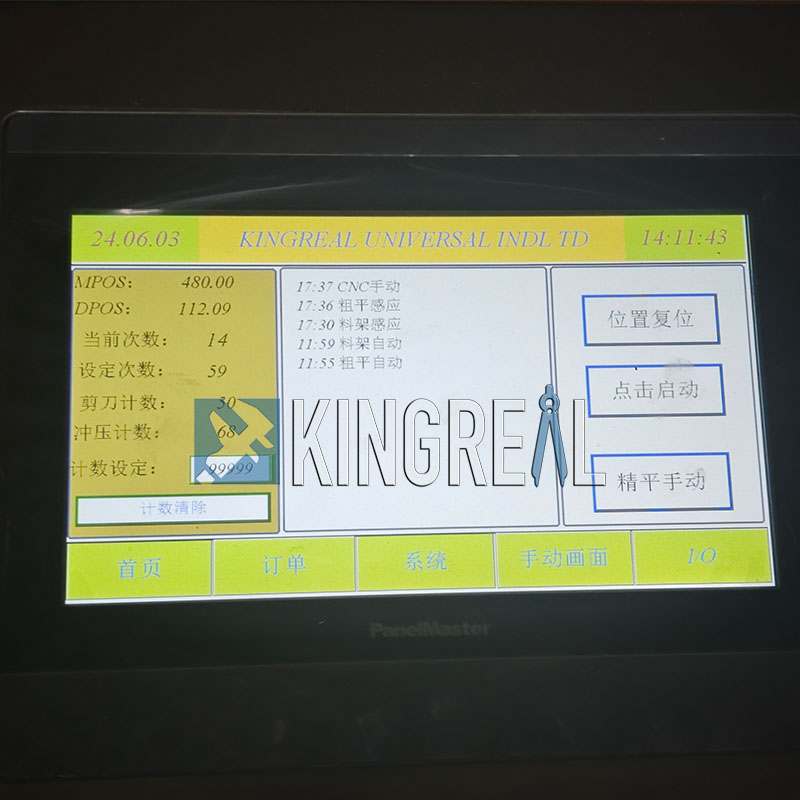

The test results show:

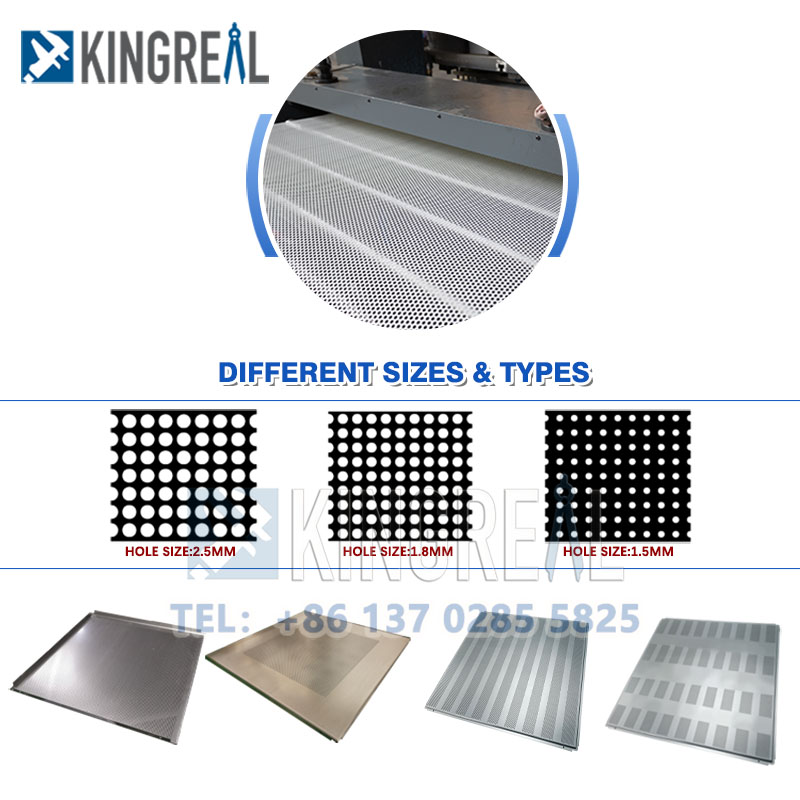

● KINGREAL CEILING MACHINERY coil perforation line can easily punch holes of various shapes such as round, square, oblong, and slot, straight line and staggered hole patterns on metal plates by replacing the punching die.

● KINGREAL CEILING MACHINERY perforated punching machine ensures uniform hole size without error.

● High-speed punching, the maximum speed can reach 180spm/min, and the speed can be adjusted. Customers can adjust it according to actual production needs.

● After the metal coil is leveled by the precision straightener, the plate is flat, making preliminary preparations for subsequent punching processing.

2.KINGREAL CEILING MACHINERY Coil Perforation Line

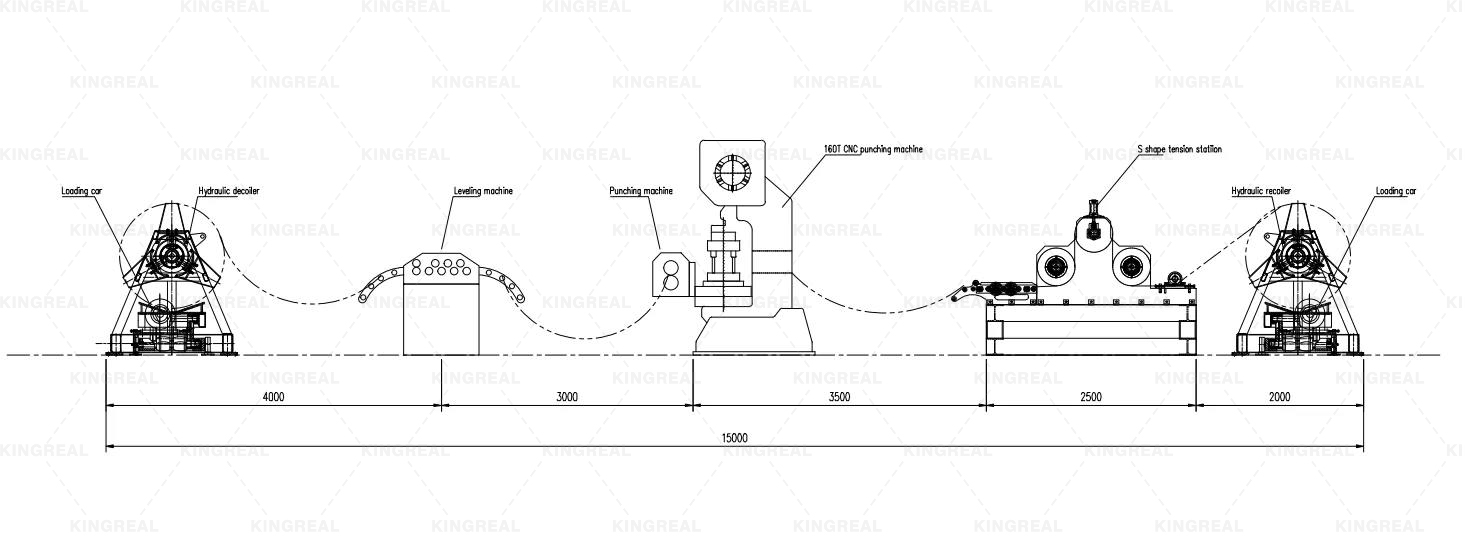

2.1 The workflow of perforated punching machine

2.2 Advantages of perforated punching machine

The coil perforation line is an indispensable equipment in the metal processing industry. Especially in the context of increasingly diversified modern production needs, choosing an efficient, safe and customized punching line is crucial to the production efficiency and quality of the finished product of the enterprise. KINGREAL CEILING MACHINERY coil perforation line has become the first choice of many customers due to its versatility, reliability and flexibility. The following are the four major advantages of KINGREAL CEILING MACHINERY coil perforation line:

① Compatible with a variety of metal raw materials

KINGREAL CEILING MACHINERY perforated punching machine is compatible with a variety of metal raw materials, including steel, aluminum, stainless steel and special alloys. This compatibility allows customers to flexibly choose different metal materials according to their own production needs.

- Adapt to diversified production needs: In the case of changing market demand, companies often need to produce finished products of different materials. The multi-material compatibility of KINGREAL CEILING MACHINERY perforated punching machine provides customers with more choices and avoids the trouble of frequent equipment replacement.

- High-precision processing: Whether it is stainless steel with higher hardness or aluminum with softer texture, KINGREAL CEILING MACHINERY coil perforation line can maintain consistent punching accuracy to ensure the high quality of the finished product.

② Excellent safety performance

The KINGREAL CEILING MACHINERY coil perforation line is equipped with an emergency stop device, which can stop operation immediately when abnormal operation or potential problems are detected to ensure the safety of workers.

- Real-time monitoring: The intelligent monitoring system built into the equipment can capture abnormal conditions in operation in real time, such as improper placement of the plate or obstruction of the punching head.

- Risk reduction: Through the emergency stop function, the machine can avoid equipment damage or worker injury at the first time, minimizing possible production risks.

- Safety training: KINGREAL CEILING MACHINERY also provides customers with detailed safety operation training to ensure that workers can operate the equipment correctly in daily use.

③ Customized design

KINGREAL CEILING MACHINERY provides highly customized machine manufacturing solutions, which are completely guided by the actual production needs of customers.

- Multi-dimensional customization: Customers can make requirements based on the thickness of metal materials, punching patterns, aperture size, punching speed and other aspects, and KINGREAL CEILING MACHINERY can provide tailor-made solutions.

- Flexible response to market changes: As the market demand for personalized products increases, customized coil perforation lines can help customers quickly adjust production plans to meet different order requirements.

- Optimize production efficiency: Through customized design, the machine can fit the customer's production process to the greatest extent, reducing unnecessary waste and adjustment time.

④ Suitable for a variety of different finished product processing

KINGREAL CEILING MACHINERY perforated punching machine can not only be used alone, but also can be matched with other machines to adapt to a variety of processing occasions.

- Metal Ceiling production: The coil perforation line can be used in conjunction with the metal ceiling production line to produce high-quality perforated metal ceilings, which are widely used in the building decoration industry. |  |

- Wallboard manufacturing: After matching the cutting station, the punched metal sheet can be cut into the length specified by the customer for subsequent manufacturing of finished products such as punched wall panels. |  |

- Automatic recoiler: The perforated punching machine can also be connected to the recoiler to directly roll the punched metal sheet into a finished product for the manufacture of products for specific purposes such as bread trays. |  |

3. KINGREAL CEILING MACHINERY's comprehensive advantages

KINGREAL CEILING MACHINERY not only excels in the technology of the perforated punching machine, but also has significant competitive advantages in service and experience. The following are the three core advantages of KINGREAL CEILING MACHINERY as a metal processing equipment supplier:

① Rich industry experience

KINGREAL CEILING MACHINERY has more than 20 years of experience in machine manufacturing and has established close cooperative relations with customers in India, Russia, Bangladesh, Brazil, Greece, South Korea, the United States and other countries.

- Deep understanding of market demand: Through years of industry accumulation, KINGREAL CEILING MACHINERY has a deep understanding of the market demand and technical standards of different countries and regions, and can quickly respond to customers' special needs.

- Superb technology: Long-term production practice has enabled KINGREAL CEILING MACHINERY to know every detail of equipment manufacturing and ensure stable and reliable product quality.

② Factory visit service

KINGREAL CEILING MACHINERY welcomes customers to visit the factory and observe the operation of the perforated punching machine at close range.

- Professional reception: KINGREAL CEILING MACHINERY provides pick-up and drop-off services, and arranges professionals to accompany customers throughout the process, explaining the technical characteristics and operating points of the equipment in detail.

- Practical experience: Customers can operate the machine in person and verify the performance of the equipment by measuring the accuracy of the finished product, enhancing their trust in the product.

③ Comprehensive installation service

KINGREAL CEILING MACHINERY provides comprehensive installation services to ensure that customers can smoothly put into production.

- On-site installation: When the perforated punching machine is delivered to the customer's factory, KINGREAL CEILING MACHINERY will send experienced engineers to the site to install the equipment and ensure that the equipment is debugged to the best state.

- Operation training: Engineers will provide comprehensive operation training for customers' workers, including basic machine operation, maintenance techniques and solutions to common problems.

- Long-term support: KINGREAL CEILING MACHINERY also provides follow-up technical support services. Customers can contact engineers at any time for help to ensure the long-term and efficient operation of the equipment.

Get the latest price? We'll respond as soon as possible(within 12 hours)