False Ceiling Machine Shipped to India

KINGREAL CEILING MACHINERY False Ceiling Machine Shipped to India

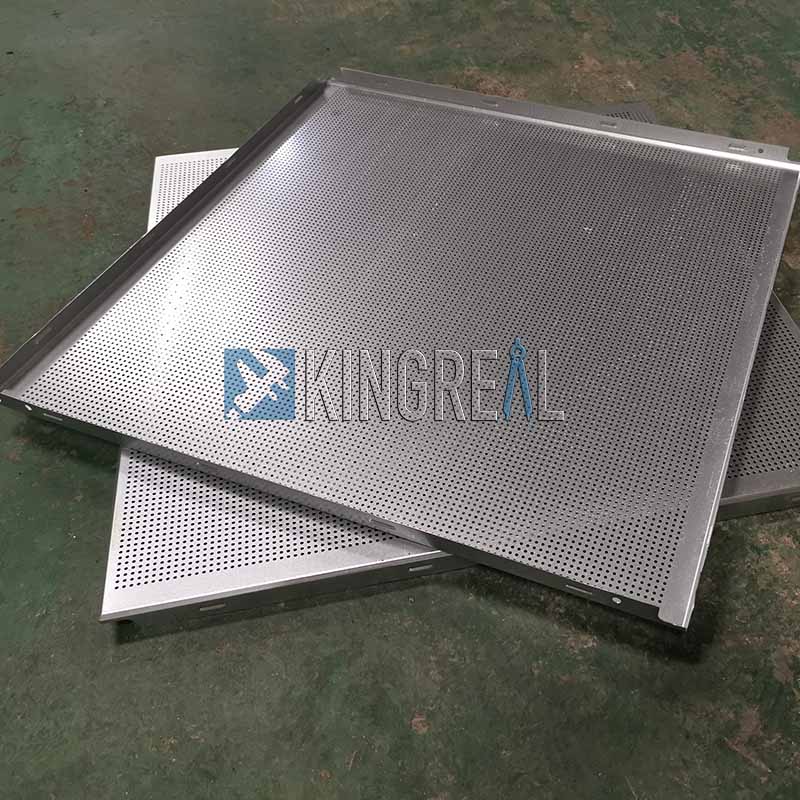

Recently, KINGREAL CEILING MACHINERY's metal ceiling panels making machine has successfully completed manufacturing and passed the strict machine test and finished product accuracy test by engineers.

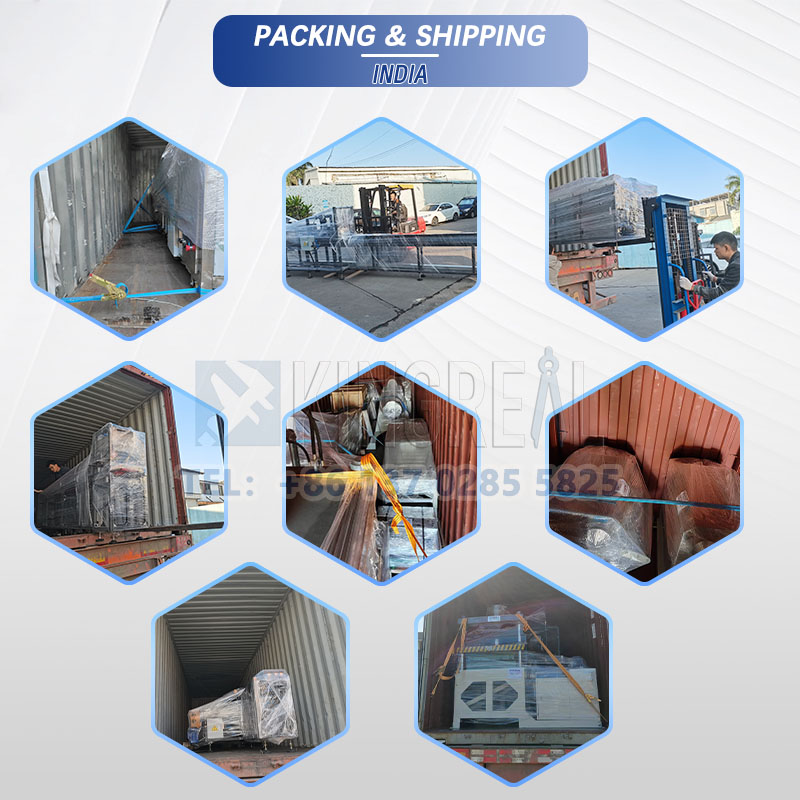

It was finally confirmed that the machine can run stably and the accuracy error is controlled within ±0.1mm. The false ceiling machine can efficiently manufacture ceilings of different sizes such as 30x30cm, 60x60cm, 60x120cm, and has passed quality inspection to ensure that each ceiling meets international quality standards. The false ceiling machine has now been shipped to the Indian customer factory.

KINGREAL CEILING MACHINERY's false ceiling machine has been widely recognized for its high precision, high efficiency and high degree of automation. The advantages and core features of this metal ceiling panels making machine will be introduced in detail below.

Advantages of KINGREAL CEILING MACHINERY's false ceiling machine

Semi-automatic production equipment

(1) High-precision control

KINGREAL CEILING MACHINERY's semi-automatic metal ceiling panels making machine is equipped with an advanced automatic control system, which can accurately control the operation of each link through precise mechanical movement and sensor systems. This allows the size error of each ceiling to be controlled within ±0.1mm, ensuring the accuracy and consistency of the finished product.

(2) Reduce manual intervention

The large-scale application of semi-automated metal ceiling production lines has greatly reduced the chances of manual intervention in the production process. This not only improves production efficiency, but also reduces the incidence of human errors. At the same time, due to the high degree of automation, labor costs can be greatly reduced, and the overall operating costs of the enterprise are also effectively controlled.

(3) Improve production efficiency

The automation level of the KINGREAL CEILING MACHINERY metal ceiling panels making machine greatly improves the production speed. The entire production process from unwinding to discharging only takes 5-6 pieces per minute, and the production speed far exceeds the efficiency of traditional manual operation. At the same time, the production speed can be adjusted on the control panel according to customer needs, and flexibly respond to different production needs.

(4) Product consistency and stability

The semi-automated metal ceiling production line ensures that each link can be strictly executed according to the set procedures, which not only improves production efficiency, but also ensures the consistency and stability of each batch of ceilings, and reduces errors and instability caused by manual operation.

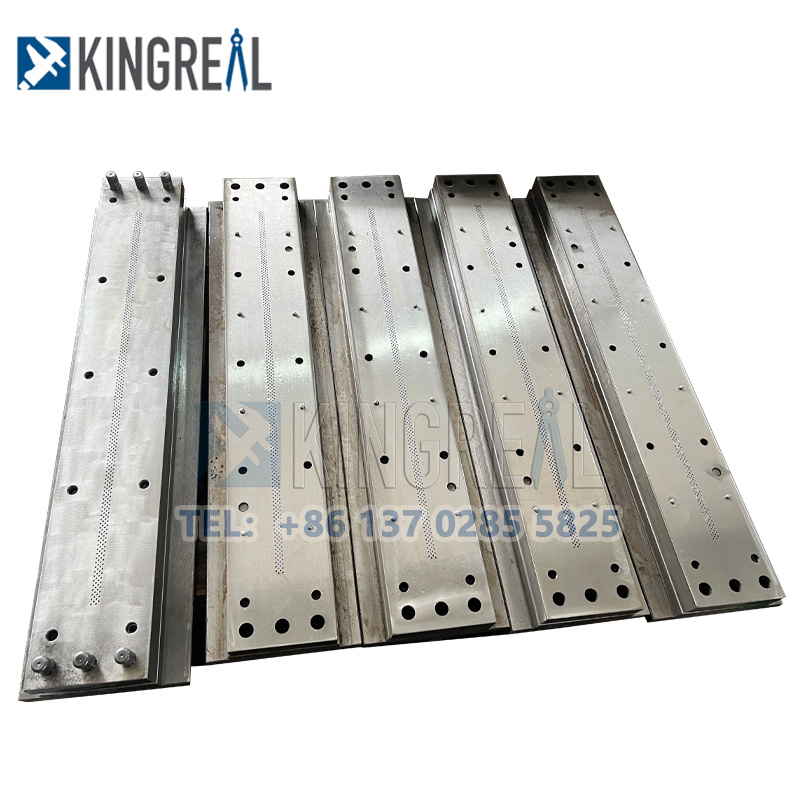

Customized metal ceiling production line

KINGREAL CEILING MACHINERY fully considers the production needs and industry characteristics of different customers when designing and manufacturing metal ceiling production lines, and provides customized solutions. This customized production line can not only meet the special needs of customers, but also optimize the design according to the actual production situation.

(1) Personalized design

KINGREAL CEILING MACHINERY is tailored according to the actual production needs of customers or the samples provided. The components and machine parameters of each ceiling production line will be adjusted accordingly according to the specific requirements of customers. For example, the length, width, processing speed and required process of the production line will be tailored according to the needs of different customers.

(2) Strong flexibility

KINGREAL CEILING MACHINERY's customized metal ceiling production line has strong flexibility. Whether it is the production of small batches of special customized products or large-scale standardized production, it can provide corresponding solutions. This flexibility helps customers better cope with market changes and fluctuations in production requirements.

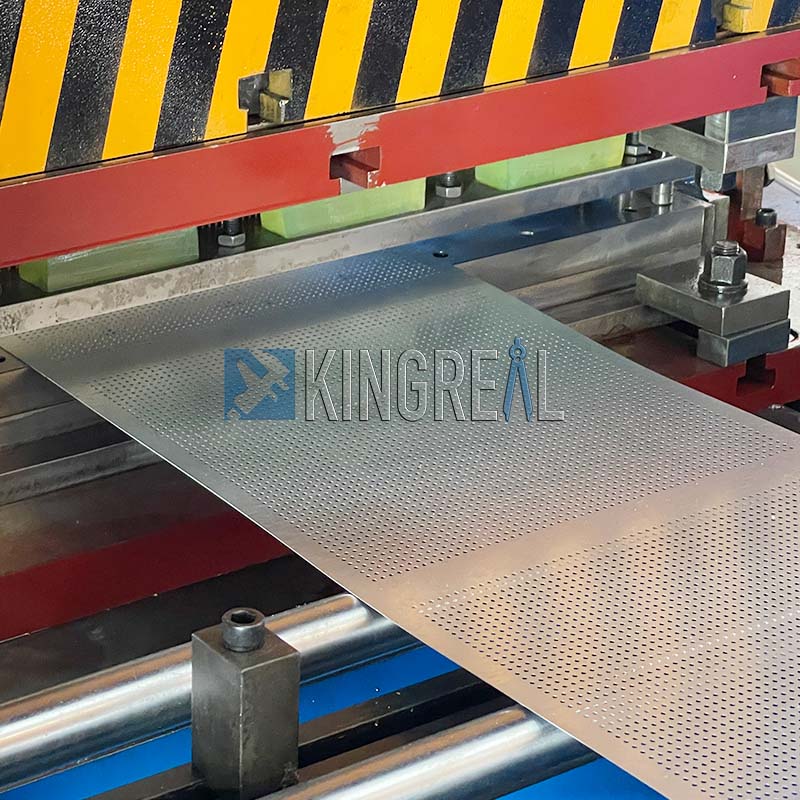

Special punching molds

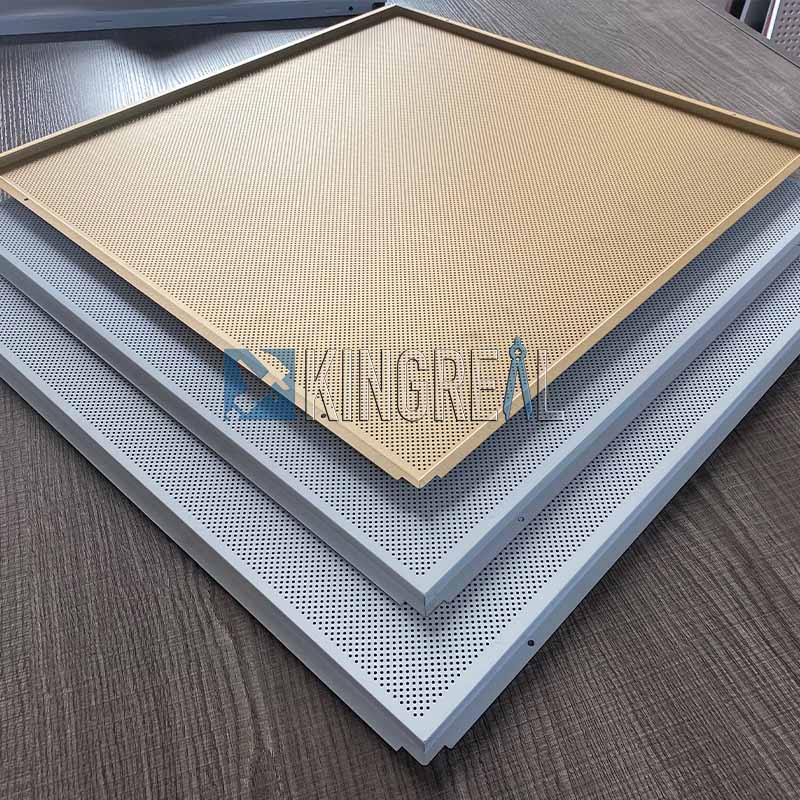

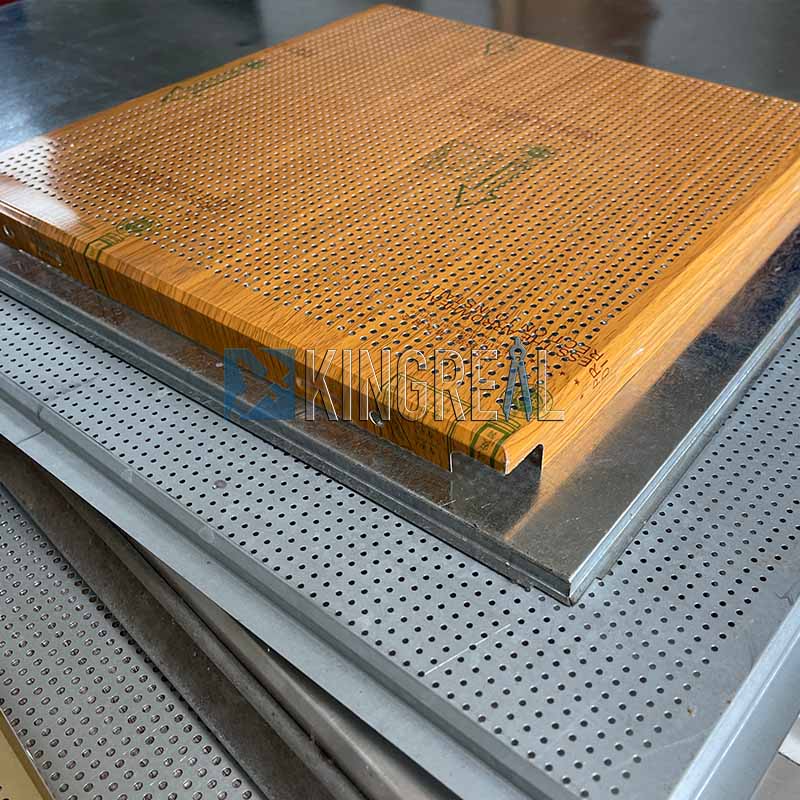

Punching is a key link in the ceiling production process. In order to meet the product needs of different customers, KINGREAL CEILING MACHINERY provides special punching dies, which can design and produce specific hole types and apertures according to customer drawings.

(1) High-quality mold materials

KINGREAL CEILING MACHINERY's molds are usually made of CR12 or CR12MOV materials. These materials are heat-treated to HRC58-60 degrees, have extremely high wear resistance and impact resistance, and can ensure the long-term stability and precision of the mold.

(2) Design according to customer requirements

KINGREAL CEILING MACHINERY can design various complex hole types and apertures according to the specific requirements of customers. If the customer has special customization needs, KINGREAL CEILING MACHINERY will provide a detailed design plan and produce according to the customer's drawings to ensure that the hole type and aperture of each ceiling meet the customer's requirements.

Compatible with a variety of metal materials

One of the biggest features of KINGREAL CEILING MACHINERY's metal ceiling panels making machine is its strong adaptability and ability to handle different types of metal materials. This makes the production line extremely flexible and able to meet the needs of different industries.

(1) Compatibility with multiple metal materials

The KINGREAL CEILING MACHINERY metal ceiling panels making machine is compatible with a variety of metal materials such as stainless steel, aluminum, iron, galvanized steel, cold-rolled steel, hot-rolled steel, copper, brass, titanium, etc. This makes the false ceiling machine not only suitable for general ceiling production, but also can produce ceilings of different materials and specifications according to customer needs, greatly improving the scope of application of the false ceiling machine.

(2) Flexible material switching

Different metal materials have different requirements for production processes. The KINGREAL CEILING MACHINERY false ceiling machine can adjust the processing technology according to different raw materials to ensure that the ceiling of each material can achieve the best production effect.

High-speed production

Production efficiency is an important measure of the metal ceiling panels making machine. The high-speed production capacity of the KINGREAL CEILING MACHINERY false ceiling machine is a highlight. By optimizing the production process and introducing an efficient automation system, the KINGREAL CEILING MACHINERY metal ceiling panels making machine can significantly increase the production speed and help customers shorten the production cycle.

(1) Fast production speed

The production speed of KINGREAL CEILING MACHINERY's false ceiling machine is as high as 5-6 pieces per minute, which means that customers can produce more ceilings in the same time and significantly improve production efficiency.

(2) Flexible adjustment of production speed

According to the actual needs of customers, the production speed of the false ceiling machine can be adjusted on the control panel. This flexible speed adjustment capability enables customers to flexibly adjust the production speed according to the urgency of the order or the production load to maximize production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)