How to Prevent High Oil Temperature in Press Bending Machine?

2024-11-07 16:05

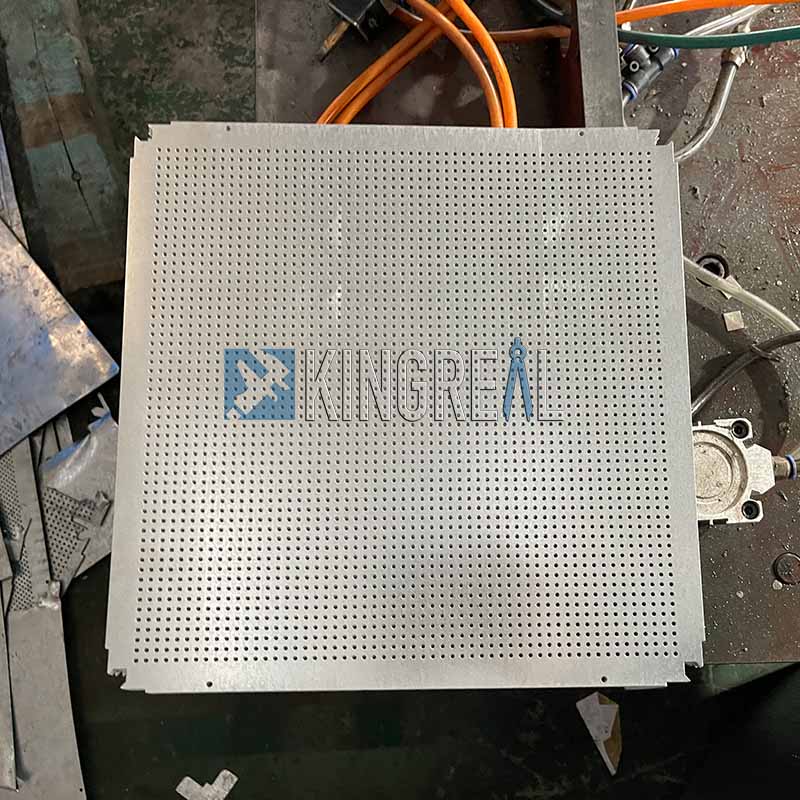

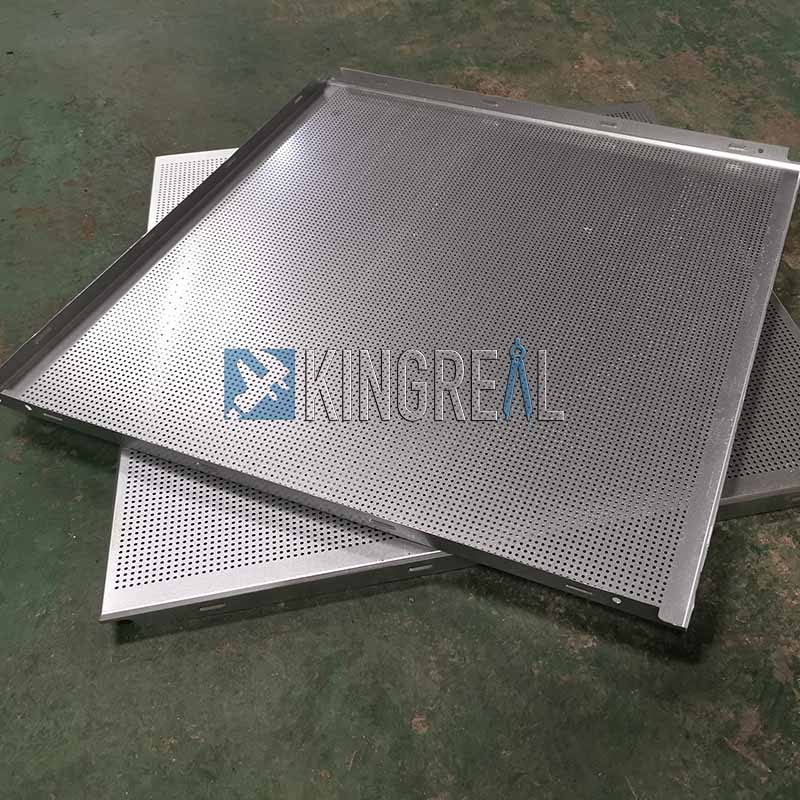

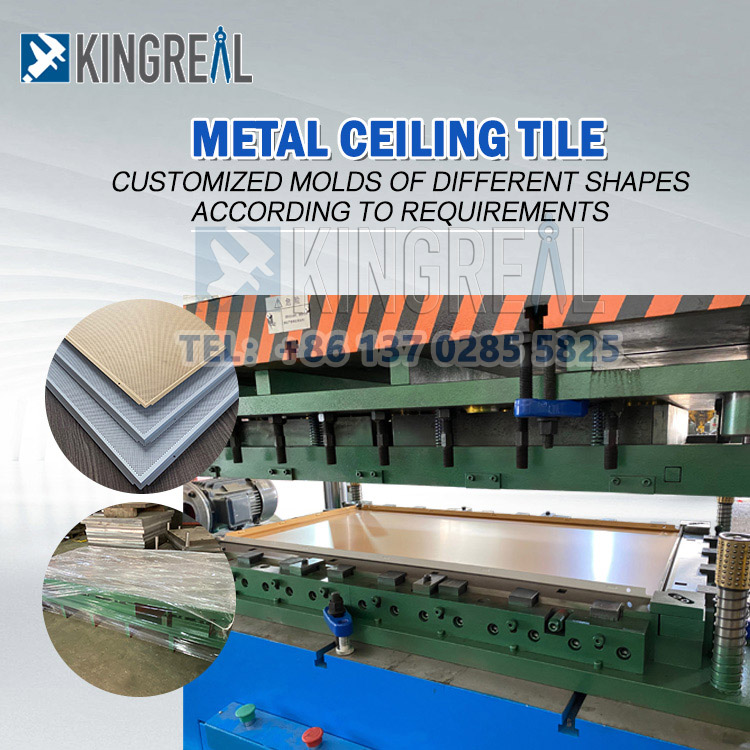

KINGREAL CEILING MACHINERY metal ceiling bending machine is suitable for bending 120*60CM ceiling, 60*60CM metal ceiling, 30*30CM aluminum ceiling and other different sizes of metal ceiling. It can be combined with semi-automatic metal ceiling tile production line to realize the production from metal sheet to ceiling molding.

In the daily operation of the metal sheet bending machine, many people will encounter the oil temperature is too high. So what can be done to avoid this problem in the process of using the press bending machine? Today's article will give you the answer.

How to Prevent High Oil Temperature in Press Bending Machine?

1. Use the hydraulic oil recommended by the manufacturer of the hydraulic press and the hydraulic oil with the appropriate viscosity. If the hydraulic oil has a high viscosity, especially in areas where the ambient temperature is relatively low, it will cause an increase in flow friction and overheating.

2. Keep the outside and inside of the oil system clean. The contaminants outside the system can isolate and hinder normal oil cooling. The contaminants inside the system will cause wear and tear and cause oil leakage. Both situations will occur. Cause heat generation.

3. The hose should be clamped and positioned reliably, and the pump, hydraulic cylinder and other hydraulic components should be replaced in time when they are worn out. Because worn components will increase the leakage, the pump will output full flow for a long time, and the oil passing through the narrow leakage gap will cause a large pressure drop. The increase of time in the case of slow flow output also increases fluid friction. The time for which the force is generated, therefore, the temperature of the oil will rise.

4. Regularly replace the filter element of the metal ceiling tile bending forming machine to avoid clogging of the filter.

5. Regularly check the water cooler of the metal ceiling tile bending forming machine and regularly descale the water cooler.

6. Excessive oil return pressure is also one of the reasons for high oil temperature. The reason for the increase of the backup pressure should be checked and eliminated.

7. Check the fluid level of the oil tank of the metal ceiling tile bending forming machine frequently. If the oil level is too low, the system will not have enough fluid to take away the heat.

Features of KINGREAL CEILING MACHINERY Press Bending Machine

1. High degree of precision

KINGREAL CEILING MACHINERY Bending Forming Press adopts a servo motor to realize high precision positioning and bending.

2. Flexible forming

The machine is compatible with different sizes and different types of metal ceiling tiles. The sizes of ceiling tiles can be 30*30cm/ 60*60cm / 60*120cm, and the types of ceiling tiles can be clip-in, lay-in etc.

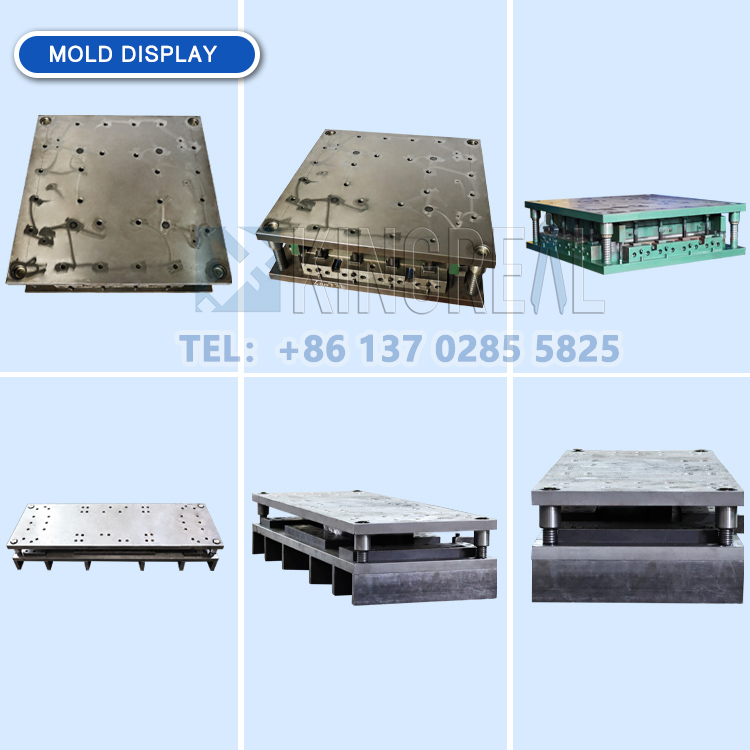

3. Easily change the molds

KINGREAL CEILING MACHINERY also provides molds, changing molds is convenient and fast, suitable for you to quickly switch between different productions, greatly improving production efficiency. KINGREAL CEILING MACHINERY can not only provide molds but also provide technical support services.

If you have any questions about hydraulic press forming machine, please contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)