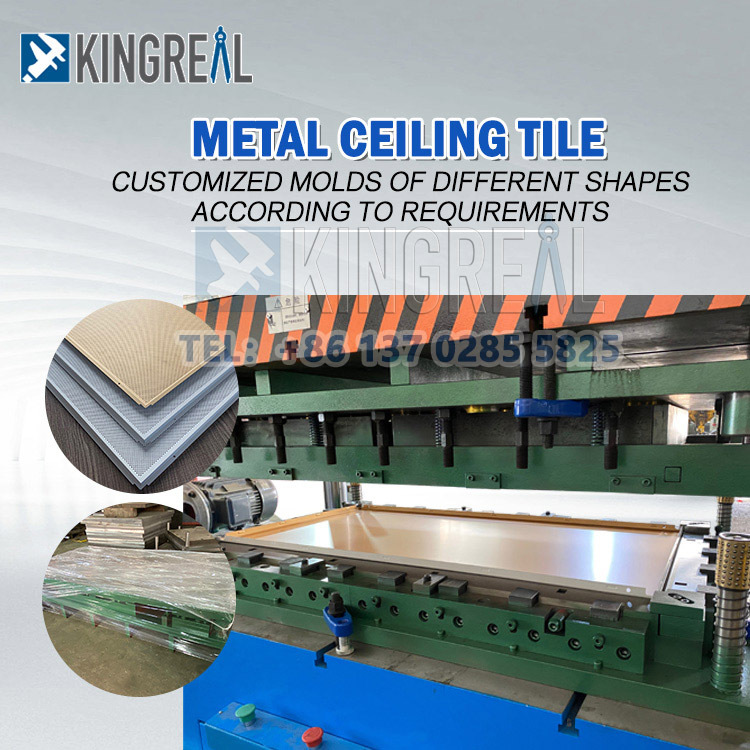

Metal Ceiling Tiles Bending Forming Machine

KINGREAL CEILING MACHINERY Metal Ceiling Tile Bending Forming Machine is driven by hydraulic system, can realize continuous production. This hydraulic press forming machine is characterized by high degree of precision and high speed, is the best choice for your metal plate bending.

- KINGREAL CEILING MACHINERY

- China

- 60 Days

- 9999

Details

Video About Metal Sheet Bending Machine

What KINGREAL CEILING MACHINERY can Provide

For more than 20 years of accumulation, KINGREAL CEILING MACHINERY has been focusing on design - production - installation - after-sales. KINGREAL CEILING MACHINERY is able to customize production solutions according to customer's drawings and specific parameter requirements and stocked many successful customized roll forming machine cases.

Description of Metal Ceiling Tile Bending Machine

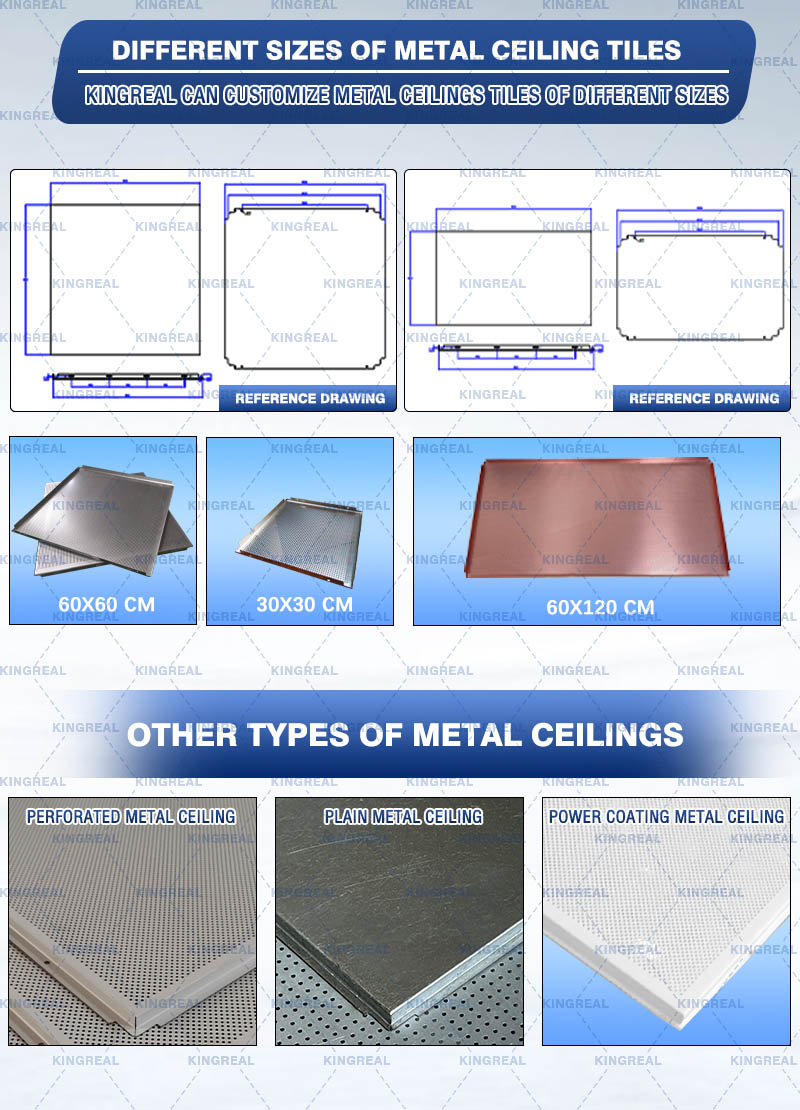

KINGREAL CEILING MACHINERY Metal Ceiling Tile Press Bending Machine is for the bending forming of different sizes of metal ceiling tiles including 120*60CM suspended ceiling panels, 60*60CM metal ceiling tiles, 30*30CM aluminum ceiling tiles. It can be combinated with semi-automatic metal ceiling tile production line to realize the production from coil to ceiling molding.

KINGREAL CEILING MACHINERY hydraulic press forming machine can do the bending forming of CLIP IN, LAY IN, Tegular on tiles by changing different bending forming mold sets. With KINGREAL CEILING MACHINERY's specially designed auto feeding system, KINGREAL CEILING MACHINERY metal sheet bending machine can produce the metal ceiling tiles full automatically.

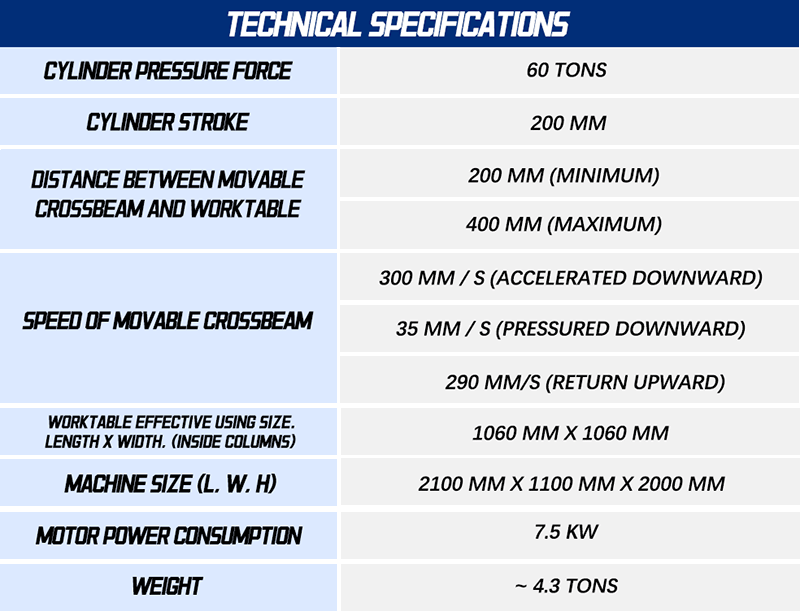

Parameter of Press Bending Machine

What KINGREAL CEILING MACHINERY Hydraulic Press Forming Machine can Provide

(1) Facilitated Production

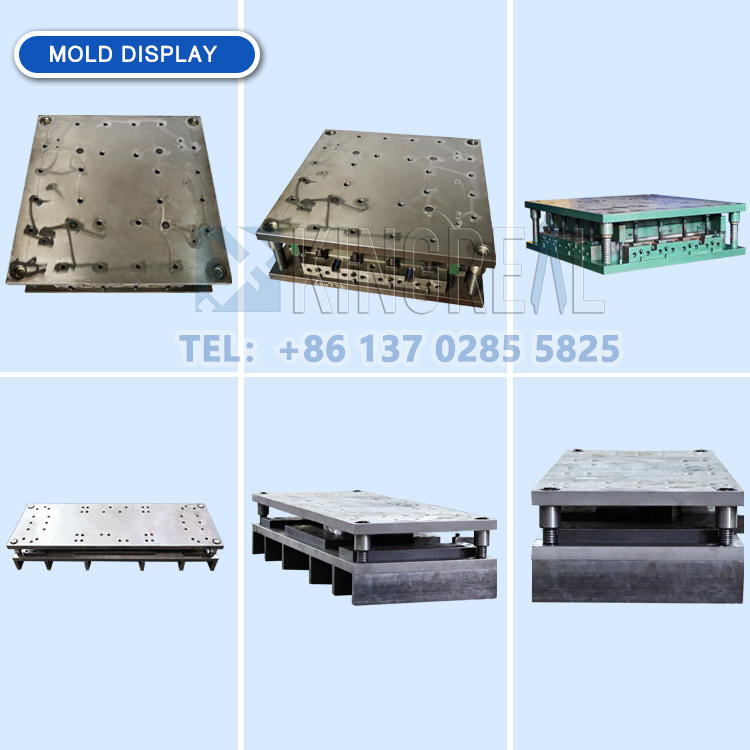

KINGREAL CEILING MACHINERY hydraulic press bending machine just needs to replace the mold to achieve bending forming of metal ceiling tiles' different sizes and types. The operation is easy, can effectively reduce personnel training costs and increase production capacity.

(2) High Precision Metal Ceiling Tiles

Servo motor is adopted in KINGREAL CEILING MACHINERY metal ceiling tile bending forming machine, which is key to realizing high precision positioning and bending and the 60tons cylinder pressure ensures the precision of the finished metal ceiling panels.

(3) Long Service Life

The body of the metal sheet bending machine is made of steel structure, which has the advantages of strong load-bearing capacity and stable operation, it greatly extends the service life of the machine and also ensures the stability of the machining process.

Customized Design

With KINGREAL CEILING MACHINERY developed auto feed manipulator, auto turn and auto stack system, it can achieve full automatic production of metal ceiling tiles. The machine is featured with easy to operate, stable running, high speed output and can also avoid working injuries.

After years of experience accumulation,KINGREAL CEILING MACHINERY has successfully customized diverse solutions in different metal ceiling production areas, such as Punching Press with Acoustic Baffle Production, Acoustic Metal Ceiling Production etc.. If you have special metal ceiling production needs, welcome to contact us!

Application Of Metal Sheet Bending Machine

By changing different mold sets, KINGREAL CEILING MACHINERY machine can produce CLIP IN ceiling tiles, LAY IN suspended metal ceiling boards, Tegular on square metal ceiling plates, LAY ON ceiling tiles, Access Panel and also other different types of products. KINGREAL CEILING MACHINERY hydraulic press bending machine is equipped with a safety light curtain to ensure safety production and continously production.

KINGREAL CEILING MACHINERY machine can bend forming different sizes of metal ceiling tiles, most common products including 30*30CM aluminum ceiling tiles, 60*60CM metal ceiling tiles, 60*120CM metal ceiling tiles, 30*120CM ceiling boards, 45*45CM, 60*180CM, 120*120CM suspended ceiling system.

Related Project

A high-performance Hydraulic Press Forming Machine from KINGREAL CEILING MACHINERY has arrived at the factory of an Indian customer. This metal ceiling tile bending machine will be used in conjunction with the customer's existing metal ceiling production line to jointly improve production efficiency and product quality. After the Hydraulic Press Forming Machine arrived, the engineering team of KINGREAL CEILING MACHINERY quickly went to the customer's factory to carry out offline installation and commissioning work to ensure that the equipment can be put into production smoothly.

During the installation process, the engineers of KINGREAL CEILING MACHINERY first conducted a detailed inspection of the press to ensure that the Hydraulic Press Forming Machine was not damaged during transportation. Then, they connected the press with other equipment of the metal ceiling production line according to the established installation process. In order to ensure the smooth operation of the production line, the engineering team also fine-tuned the mechanical linkage part to ensure the coordination between various links.

After the installation, the engineers conducted a comprehensive functional test, including the pressure regulation, speed control and safety protection system inspection of the Metal Ceiling Tile Bending Forming Machine. This series of tests not only ensures the normal operation of the equipment, but also provides customers with operating instructions to help them quickly master the use of the metal ceiling tile bending machine.

KINGREAL CEILING MACHINERY in Diverse Exhibition

At each exhibition, KINGREAL CEILING MACHINERY carefully prepared a variety of featured machines, including metal ceiling production lines, baffle ceiling machines, open cell ceiling machines, linear strip ceiling machines and metal sheet perforation lines. These equipment attracted a lot of visitors' attention at the exhibition, showing KINGREAL CEILING MACHINERY strong strength in metal processing and building materials manufacturing.

KINGREAL CEILING MACHINERY staff will provide detailed product introductions and technical support to ensure that customers can get professional advice and solutions while understanding the products.

During the exhibition, the KINGREAL CEILING MACHINERY team had in-depth exchanges and interactions with customers from all over the world. KINGREAL CEILING MACHINERY listened carefully to customers' needs and feedback and understood their actual challenges in the production process. This face-to-face communication method enables us to respond quickly to customers' needs and provide them with tailor-made solutions.

Many visitors showed great interest in KINGREAL CEILING MACHINERY equipment and asked about technical details and cooperation opportunities. Through these interactions, KINGREAL CEILING MACHINERY not only enhanced customers' trust in the brand, but also laid a good foundation for future cooperation.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)