Metal Ceiling Machine Shipped to India

After many days of online communication between KINGREAL CEILING MACHINERY technicians and Indian customers, and inviting customers to visit KINGREAL CEILING MACHINERY factories, the customers finally ordered metal ceiling production lines from KINGREAL CEILING MACHINERY.

In order to better control the quality of the metal ceiling machines, KINGREAL CEILING MACHINERY not only built our own factory, but also established our own technical team. Before shipment, the metal ceiling production line was tested by KINGREAL CEILING MACHINERY's technical team to ensure that every mechanical and electrical component was in good condition. Now the metal ceiling machine has been successfully shipped to India!

The fully automatic metal ceiling production line is one of KINGREAL CEILING MACHINERY's best-selling machines. KINGREAL CEILING MACHINERY has been deeply involved in the field of fully automatic metal ceiling machines for more than 20 years and has successfully accumulated a lot of technical customization experience and local installation experience. KINGREAL CEILING MACHINERY is very honored to gain the trust of Indian customers. It is precisely because of the customer's recognition of our professionalism that this cooperation will be so smooth.

In the metal ceiling market, 600x600mm ceilings are in great demand, so many ceiling tile manufacturers have purchased 600x600mm metal ceiling production lines from KINGREAL CEILING MACHINERY. The main features of KINGREAL CEILING MACHINERY's metal ceiling production line are easy operation and low scrap rate, which is a very economical choice. Customers are very satisfied with the quality of our metal ceiling production line. They said that this production line not only helped them increase production, but also improved the quality of ceilings. This fully automatic metal ceiling production line has been successfully sold to India, Vietnam, Brazil and other places, and has won unanimous praise from customers all over the world.

Advantages of metal ceiling production line

①Fully automatic production line

The self-developed automatic feeding manipulator, automatic turning and automatic stacking system are adopted to realize the fully automatic production of metal ceiling tiles. This metal ceiling machine has the characteristics of easy operation, stable operation, fast output speed and avoidance of work injuries.

②Different types of metal ceilings can be produced

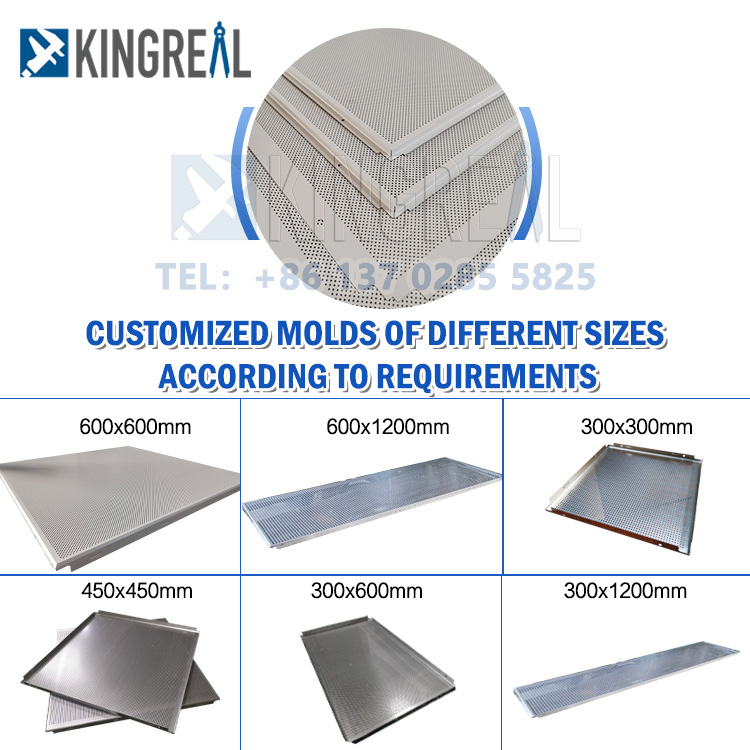

By replacing different bending plate molds, CLIP IN, LAY IN and tegular ceilings can be produced. The mold replacement is very convenient, saving time and the cost of purchasing other machines

③Reduce costs and reduce safety hazards

The fully automatic metal ceiling production line is mechanically controlled and has sensitive movements, and no manual control of accuracy is required. Reducing manpower, reducing costs for enterprises, and reducing safety hazards caused by workers' work.

④Reduce the generation of waste

The hydraulic press cuts the four corners and folds the four edges in one step. Reduce waste and save costs.

Finished Product Display

Metal ceilings are widely used in office, retail, healthcare, education and transportation. They are also durable, hygienic and can be designed to meet different aesthetic and acoustic needs and combined with lighting and other services. Metal ceiling systems come in a variety of shapes and sizes and can be used for both exterior and interior applications.

Get the latest price? We'll respond as soon as possible(within 12 hours)