Linear Strip Ceiling Machine Shipped to UK

Video About Linear Strip Ceiling Machine

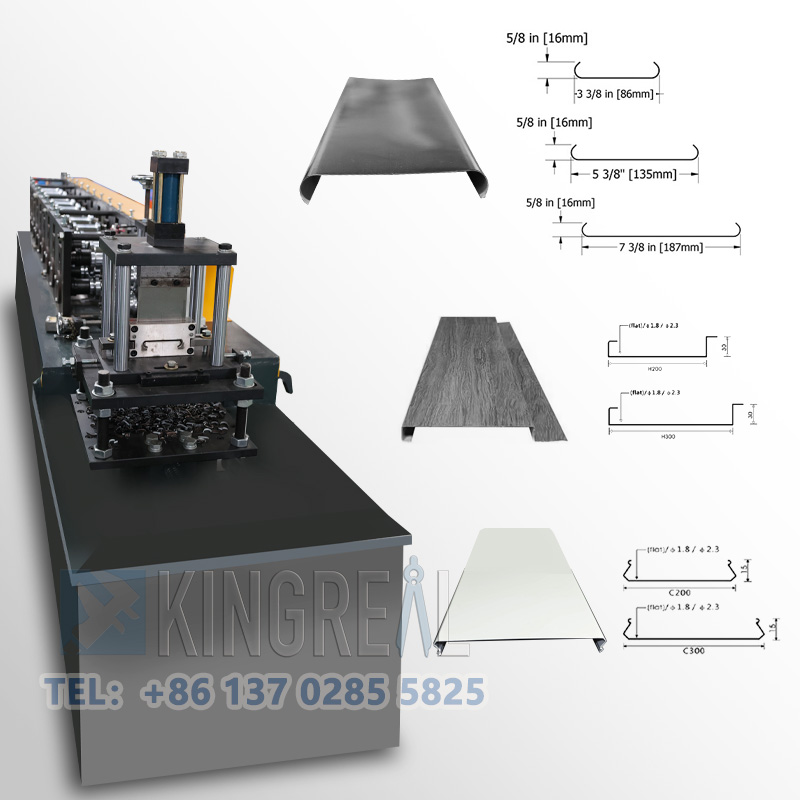

Recently, the KINGREAL CEILING MACHINERY factory successfully completed the production of a linear strip ceiling machine. After a series of rigorous trial machine processes, the staff confirmed that the production speed of the equipment can reach up to 30m/min, and it can efficiently produce strip ceilings with a width range of 100-300mm and extremely high precision, fully meeting the actual production needs of customers. At present, this high-performance equipment has been successfully shipped to the British customer factory!

What is a linear strip ceiling making machine?

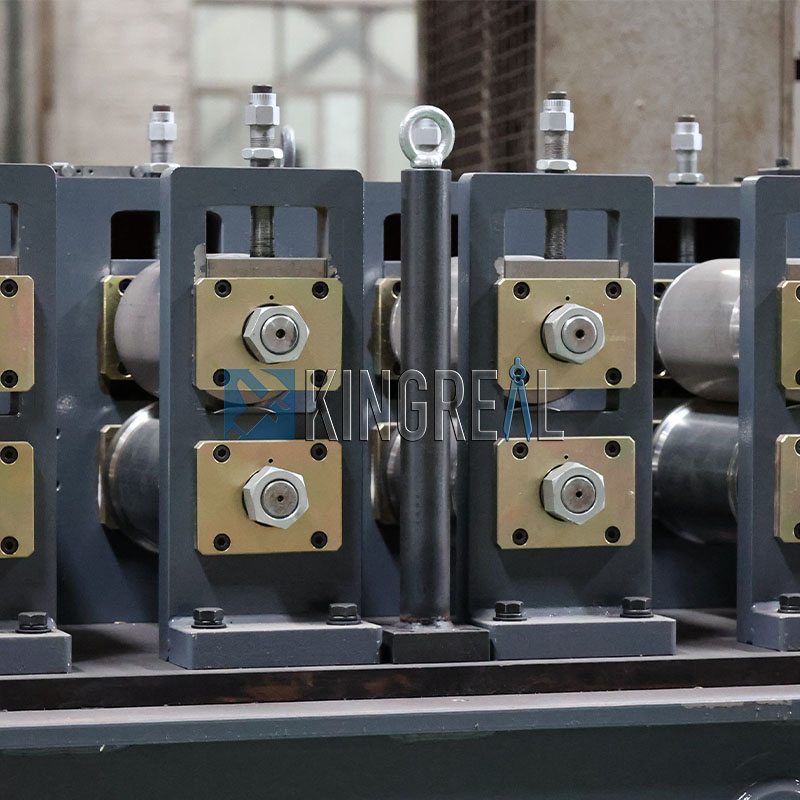

| The linear strip ceiling making machine is an automated equipment that processes metal coils into specific shapes through cold rolling forming technology. Its main working principle is to gradually press the raw materials into shape through a series of roller dies, and finally obtain a finished linear strip ceiling that meets the design requirements. Linear strip ceilings are usually made of aluminum alloy, stainless steel or galvanized steel. These materials are not only light and durable, but also have good corrosion resistance, meeting the dual needs of modern architecture for beauty and functionality. |  |

Why do we need a linear strip ceiling machine?

Linear strip ceiling machine is a kind of equipment specially used for producing strip ceilings. As an important part of modern architectural decoration, linear strip ceilings are widely used in commercial buildings, public places and home decoration due to their simple and beautiful appearance, convenient installation and strong durability. The strip ceiling making machine is the core equipment for realizing the efficient production of this building material.

Position of linear strip ceiling making machine in the market

With the rapid development of the building decoration industry, the demand for linear strip ceilings continues to grow. As a key equipment for the production of this material, the market position of linear strip ceiling making machine is also increasing. The following is the embodiment of its core position in the market:

1. Necessary equipment for the construction industry Linear strip ceilings have become an important choice for modern building decoration due to their beauty, functionality and easy installation. As the core equipment for the production of this material, the strip ceiling making machine directly promotes the popularization of strip ceilings. 2. Driving force of technological innovation The technological progress of linear strip ceiling machines, such as the improvement of automation and the application of intelligent control systems, not only improves production efficiency, but also promotes the technological upgrading of the entire building decoration materials industry.

3. Competitiveness in the international market Globally, the market demand for linear strip ceilings continues to expand, and manufacturers with advanced strip forming technology are more competitive. High-quality linear strip ceiling machines not only meet domestic demand, but also become an important export product, helping manufacturers to expand into the international market. |  |

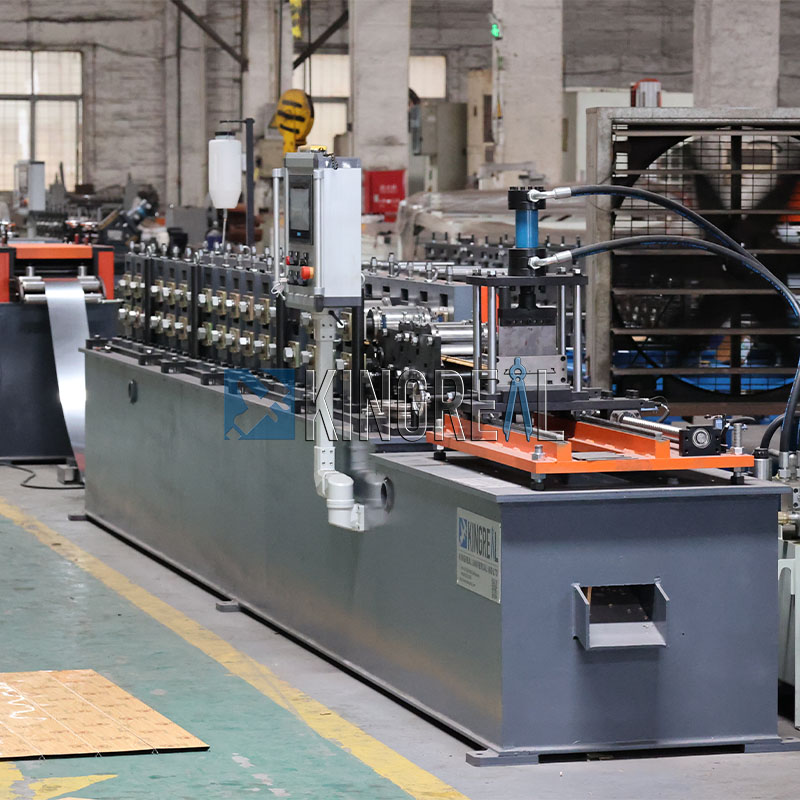

KINGREAL CEILING MACHINERY linear strip ceiling making machine

KINGREAL CEILING MACHINERY linear strip ceiling making machines are known for their simple operation, intelligence and efficiency. Its intelligent control panel and fully automatic production process significantly improve production efficiency and help customers effectively reduce time costs and labor costs. For customers who need to produce ceilings with punched linear strips, they can easily achieve this by simply adding a punching machine to the existing production line without the need to adjust the production line layout on a large scale, thus significantly reducing implementation costs and operational complexity. .

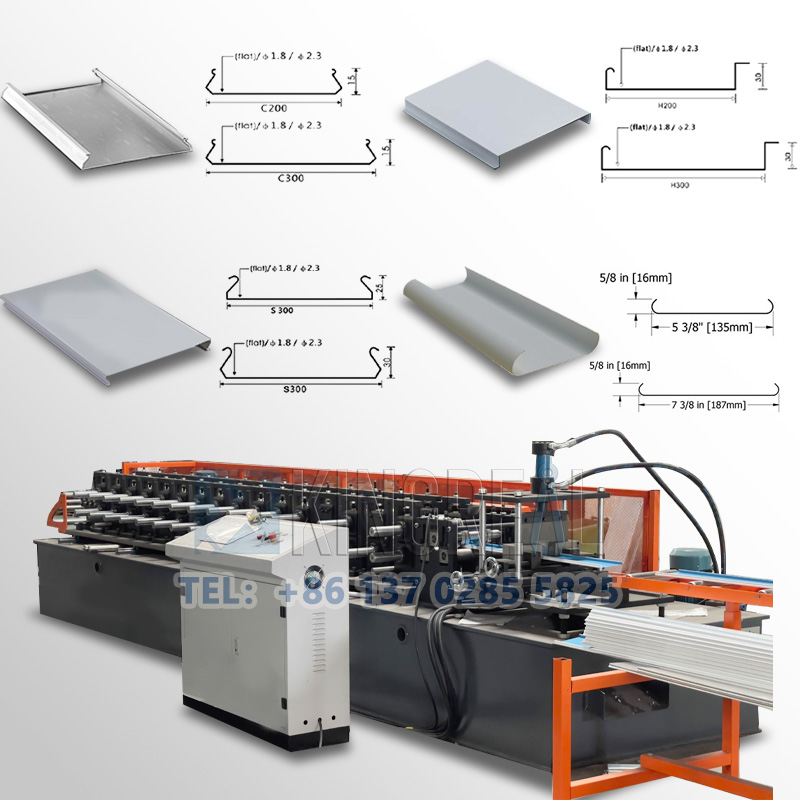

What's more worth mentioning is that the KINGREAL CEILING MACHINERY strip ceiling making machine has the advantage of being multi-purpose and can produce various types of strip ceilings (such as G, F, H, S, R, and C types). By simply changing the roller station, shearing station and mold, you can quickly switch production types to meet the diverse needs of customers.

After the equipment is delivered, KINGREAL CEILING MACHINERY provides comprehensive technical support, including operating instructions through videos or sending engineers to the customer's factory for on-site training to ensure that workers can quickly master the equipment's operating skills.

KINGREAL CEILING MACHINERY's two most popular linear strip ceiling production lines are the economical strip ceiling machine and the adjustable width strip ceiling machine. They each provide cost-effective, flexible and diverse solutions for different customer needs.

● Adjustable width linear strip ceiling machine

KINGREAL CEILING MACHINERY adjustable width linear strip ceiling machine is known for its flexibility and high precision, and is especially suitable for the following customer groups:

1. Customers with multi-size production requirements

This equipment supports the production of various strip widths and can produce strip ceilings with a width range of 100-300mm. Customers only need to adjust the equipment parameters to switch between different sizes without replacing the entire production line, which greatly saves production time and costs.

2. Customers who require high precision of finished products

KINGREAL CEILING MACHINERY adjustable width strip ceiling machine adopts advanced roller forming technology and precision mold design to ensure that each strip ceiling has accurate dimensions and smooth surface, meeting the strict requirements for product quality of high-end architectural decoration projects.

● Economical linear strip ceiling machine

The economical linear strip ceiling machine is specially designed for cost-sensitive customers and is suitable for the following scenarios:

1. Processing of light and thin metal materials

KINGREAL CEILING MACHINERY economical linear strip ceiling machine is mainly used to process light and thin metal sheets, such as aluminum alloy and galvanized steel plates, and is very suitable for projects that require low material thickness.

2. Single size production requirements

The economical linear strip ceiling machine only supports the production of a single size and is suitable for customers who have small requirements for changes in strip ceiling width. Although the accuracy is slightly lower than that of the adjustable width linear strip ceiling machine, it can fully meet the needs of customers who do not require high accuracy of finished products, especially in general decoration or small engineering projects.

Adjustable width strip ceiling machine

Economical linear strip ceiling machine

Get the latest price? We'll respond as soon as possible(within 12 hours)