U Baffle Ceiling Machine Successfully Shipped to Spain

After several days of online communication between KINGREAL CEILING MACHINERY technicians and our Spanish client, as well as an invitation for the client to visit the KINGREAL CEILING MACHINERY factory for an on-site tour, the client ultimately placed an order with us for the u baffle ceiling roll forming machine.

To better control the quality of KINGREAL CEILING MACHINERY machines, KINGREAL CEILING MACHINERY has not only established our own factory but also set up our own technical team. Before shipment, the u baffle ceiling making machine underwent testing by the KINGREAL CEILING MACHINERY technical team to ensure that every mechanical and electrical component was in perfect condition. This baffle false ceiling roll forming machine has now been successfully shipped to Spain!

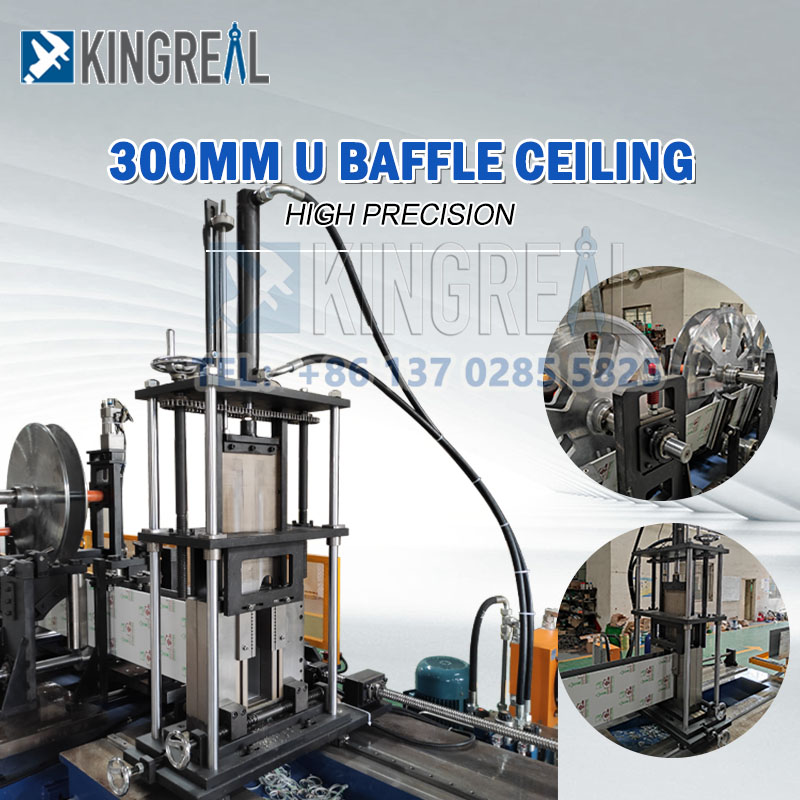

Features of the Baffle Ceiling Machine

Automatic Width Adjustment

The KINGREAL CEILING MACHINERY baffle ceiling making machine can produce u-shaped baffle ceilings of varying lengths and widths on a single machine. Dimensions are controlled by a rotary encoder and can be set via a touchscreen. Baffle ceilings range from the smallest size (30-150mm) to a maximum height of 300mm. Customers can flexibly choose the product dimensions.

Follow-Up Cutting Station

KINGREAL CEILING MACHINERY has equipped its duct production line with an advanced hydraulic follow-up cutting station, which significantly enhances the performance of the line. This follow-up cutting station synchronizes in real-time with the production speed and performs precise cuts, allowing the entire production line to achieve speeds of up to 30 meters per minute. This efficient cutting capability not only boosts production efficiency but also ensures the precision and consistency of the products.

Unique Design

The KINGREAL CEILING MACHINERY 300mm baffle false ceiling roll forming machine, is one of our most distinctive products. This production line has been specifically designed and manufactured for Hunter Douglas Group to meet the demands for high-quality, large-sized baffle ceilings. The line efficiently produces baffle ceilings with a width of up to 300mm.

Can Be Used With Other Equipment

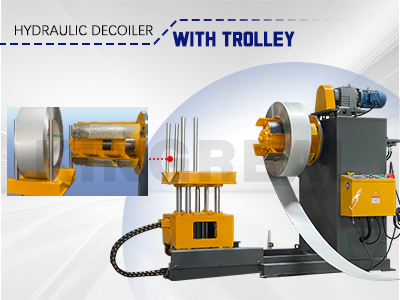

Loading Trolley

The four-column direct-acting loading trolley adopts hydraulic drive transmission with a speed of 3m/min. It can save manpower, improve production efficiency and reduce safety hazards.

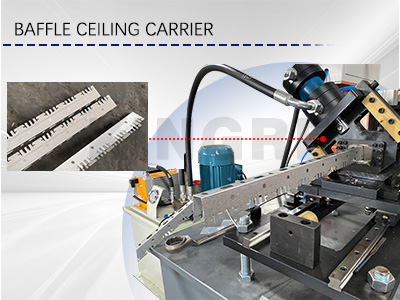

Baffle Ceiling Carrier Roll Forming Machine

The baffle ceiling carrier machine has a production speed of 5-15m/min, and the finished product accuracy is ±1.0mm. It can produce u-shaped baffle ceiling frames of corresponding sizes for installing baffle ceilings.

Diverse U Baffle Ceiling Solutions

You can choose KINGREALCEILING MACHINERY's u baffle ceiling roll forming machine according to the size requirements for producing baffle ceilings. The 150 baffle machine can produce baffle ceilings with a height range of 35-150mm and a width range of 30-100mm; the 200 baffle machine can produce u baffles with a height range of 35-200mm and a width range of 30-100mm; the 300 u baffle machine can produce baffles with a height range of 35-300mm and a width range of 50-100mm.

150mm baffle false ceiling roll forming machine

200mm baffle false ceiling roll forming machine

300mm baffle false ceiling roll forming machine

As a professional metal processing machinery manufacturer from China, KINGREAL CEILING MACHINERY has over 20 years of experience in design, production, installation, and after-sales service. KINGREAL CEILING MACHINERY thanks our Spanish client for their trust in KINGREAL CEILING MACHINERY and look forward to collaborating with more manufacturers from around the world!

Get the latest price? We'll respond as soon as possible(within 12 hours)