Baffle Ceiling Machine Shipped to Mexico

Recently, the technical team of KINGREAL CEILING MACHINERY CEILING MACHINERY carried out a strict test on the newly produced machine - U Baffle Ceiling Roll Forming Machine, by putting metal raw materials into the way of baffle ceiling production line operation to test the operation of the machine and the quality of the finished product to meet the customer's requirements. KINGREAL CEILING MACHINERY baffle ceiling production line successfully passed the inspection and has been successfully delivered to the customer's factory in Mexico!

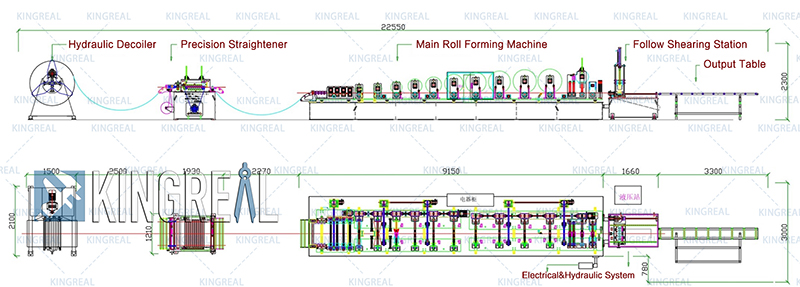

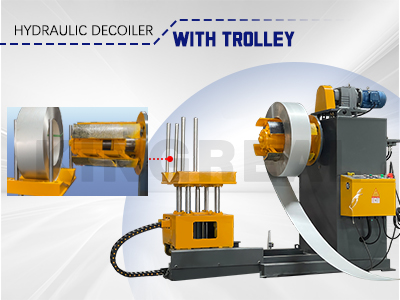

KINGREAL CEILING MACHINERY baffle ceiling machine is based on metal sheet material as raw material, can produce common metal baffle ceiling, such as U-shaped square baffle ceiling, sound-absorbing baffle ceiling, V-shaped baffle ceiling. Baffle ceiling production line is mainly composed of hydraulic decoiler, precision straightener, main roll forming machine, discharge table, electrical system, hydraulic system and shearing system.

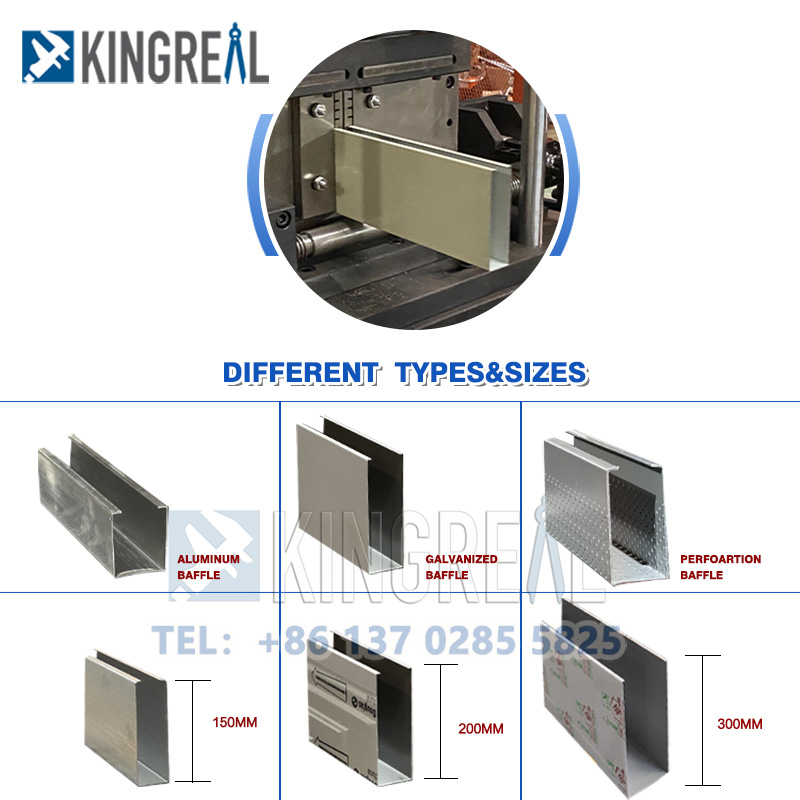

KINGREAL CEILING MACHINERY u baffle ceiling roll forming machine has three models, you can choose according to your actual production needs: 150mm height baffle ceiling machine can produce baffle ceiling height range: 35-150mm, width range: 30-100mm; 200mm height baffle ceiling machine can produce baffle ceiling height range: 35-200mm, width range: 30-100mm; 300mm height baffle ceiling machine can produce baffle ceiling height range: 35-300mm, width range: 50-100mm.

Work Flow of U Baffle Ceiling Roll Forming Machine

Advantages of Baffle Ceiling Production Line

Customized New Design

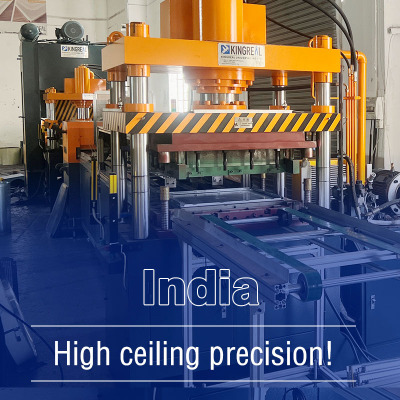

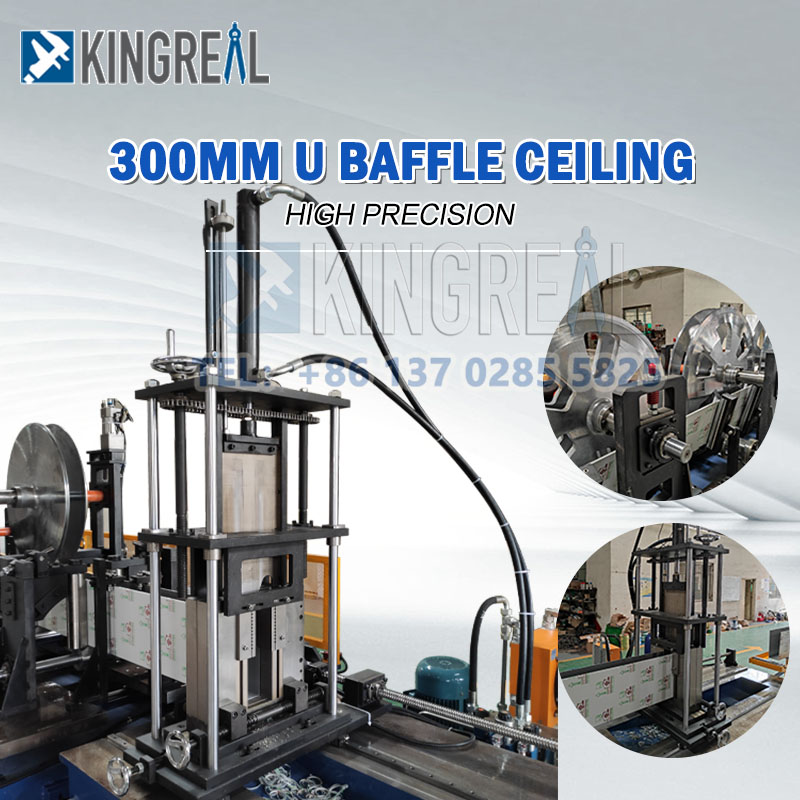

300mm height baffle ceiling machine is a machine customized by KINGREAL CEILING MACHINERY according to the actual production needs of customer Douglas, KINGREAL CEILING MACHINERY can meet the special needs of customers for baffle ceiling production size. If you have new ideas and needs for baffle production, welcome to send your drawings to KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY designers will customize your baffle ceiling production line after full communication with you.

Can Produce Different Sizes of Baffle Ceiling

You do not need to change the machine frequently to produce different sizes of baffle ceiling machines, KINGREAL CEILING MACHINERY u baffle ceiling roll forming machines can automatically adjust the width to produce different sizes of baffle ceiling.

Follow Shearing

The cutting system uses a follow shearing, you only need to enter the required cutting parameters, the system can detect the length of the material through the sensor, and control the tool at the right time to cut. Compared with stop cutting, the advantages of cutting with higher cutting efficiency and accuracy, because it can be adjusted while the material is running, reducing downtime and waste, which can greatly improve your productivity.

Optional Equipment

Trolley. The four-column direct-acting trolley adopts hydraulic transmission, and the speed is 3m/min. It can save manpower, improve production efficiency and reduce safety hazards.

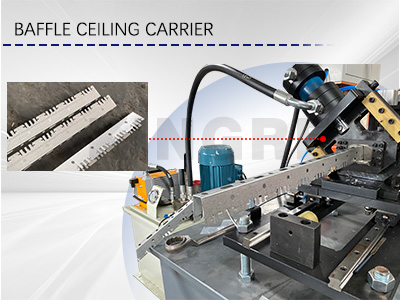

Baffle ceiling carrier machine. The production speed of the ceiling carrier machine is 5-15m/min, the finished product accuracy is ±1.0mm, and the U-shaped baffle ceiling carrier of the corresponding size can be produced for the installation of the baffle ceiling.

Components Details

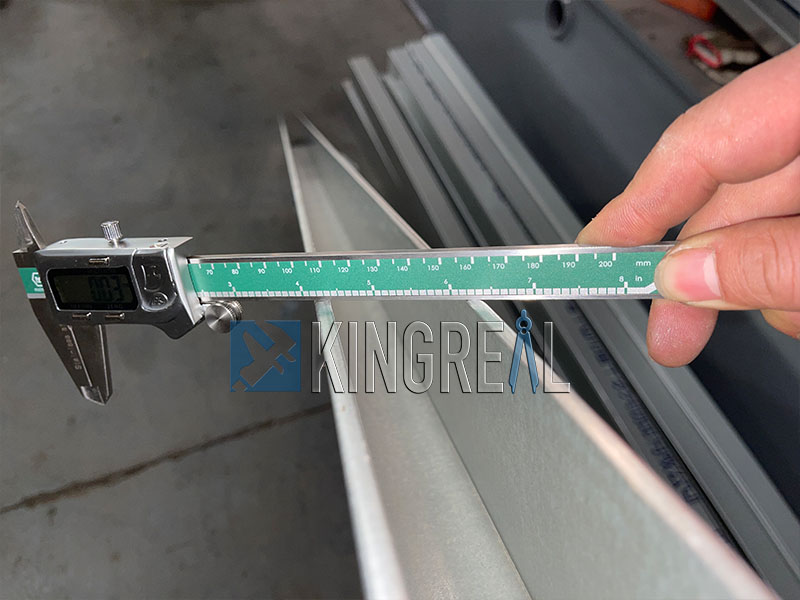

High Precision

KINGREAL CEILING MACHINERY's baffle ceiling production line is equipped with precision straighteners, which have 10 upper wheels and 11 lower wheels, for a total of 21 rollers. More rollers provide more uniform pressure and support, helping to straighten the material more effectively and reduce warping and deformation, thereby increasing the accuracy of the product.

|  |

About KINGREAL CEILING MACHINERY

KINGREAL CEILING MACHINERY is a professional manufacturer of metal ceiling machinery with extensive experience in this industry. And KINGREAL CEILING MACHINERY can provide you with strong technical support and 24 hours online service. If you are interested in the machine, you are welcome to send the drawing to the KINGREAL CEILING MACHINERY, the engineer will make a customized plan for you after full communication with you.

Get the latest price? We'll respond as soon as possible(within 12 hours)