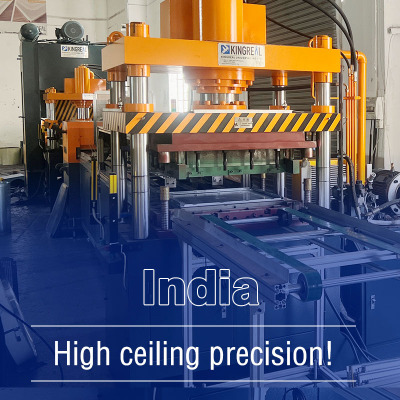

KINGREAL CEILING MACHINERY Case -- Baffle Ceiling Carrier Roll Forming Machine

Baffle Carrier Machine Shipped to UK

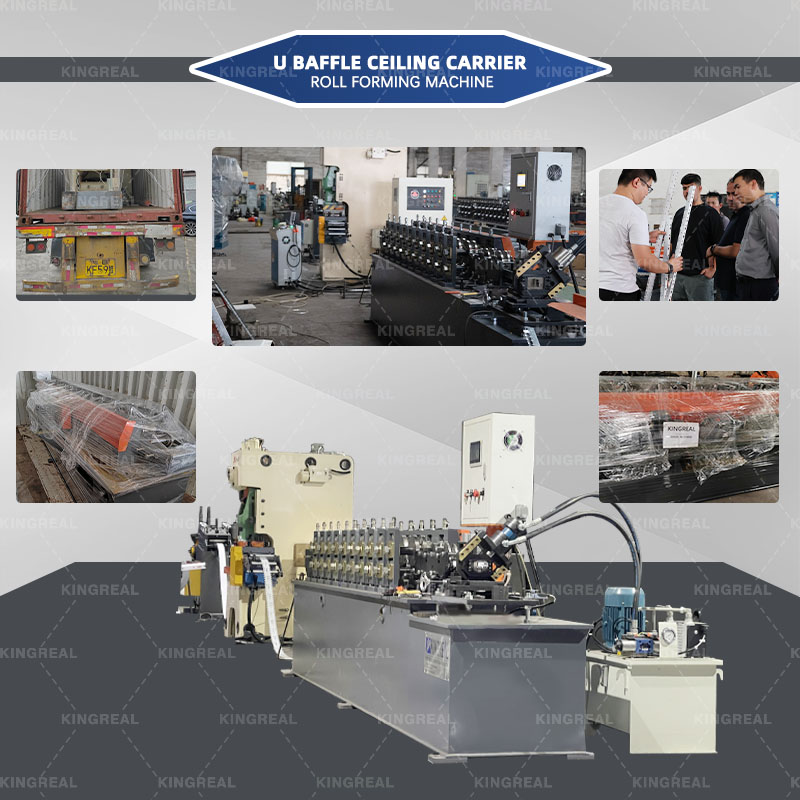

After many days of online communication between KINGREAL CEILING MACHINERY technicians and British customers, and after inviting customers to visit KINGREAL CEILING MACHINERY factory, customers have a full understanding of KINGREAL CEILING MACHINERY's baffle ceiling carrier machine, satisfied with the customized solution the engineer designed for him, he finally ordered the metal ceiling carrier machine from us.

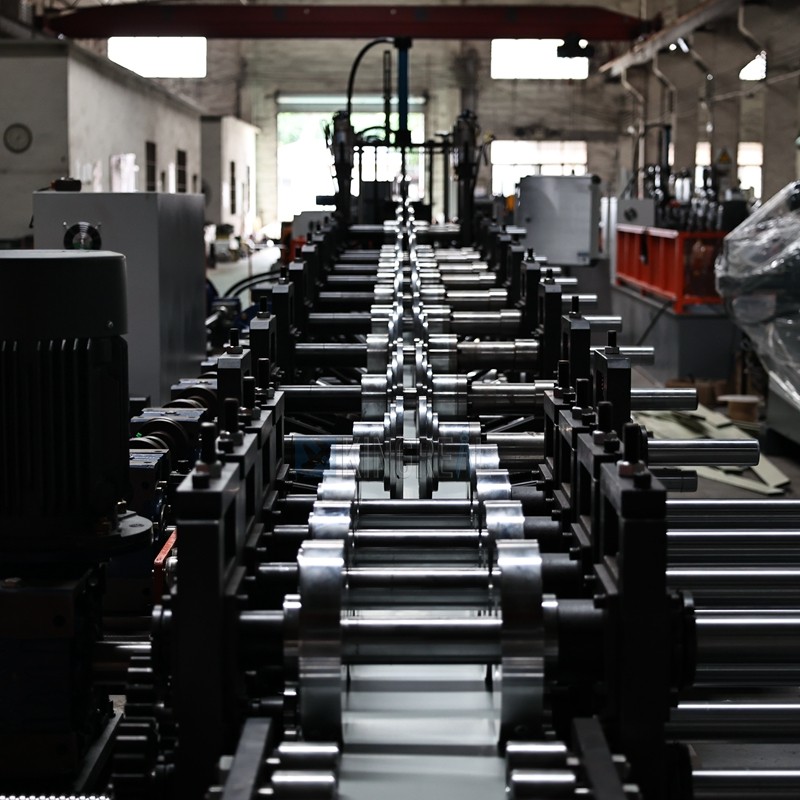

In order to better control the quality of the machines, KINGREAL CEILING MACHINERY not only set up our own factory, but also set up our own technical team. Before shipping, this ceiling carrier production line is tested by KINGREAL CEILING MACHINERY's technical team to ensure that every mechanical and electrical component is in good condition. Now the machine has been successfully shipped to the UK!

In order to maintain the uniformity of the finished u baffle ceiling, many manufacturers who purchased metal baffle ceiling making machine from KINGREAL CEILING MACHINERY will also purchase additional baffle ceiling carrier roll forming machine from us to form a complete production line with the metal baffle ceiling making machine. KINGREAL CEILING MACHINERY baffle ceiling carrier roll forming machines have been successfully sold all over the world, including Russia, Turkey, UAE, Brazil and other places.

Main Features of Baffle Ceiling Carrier Machine

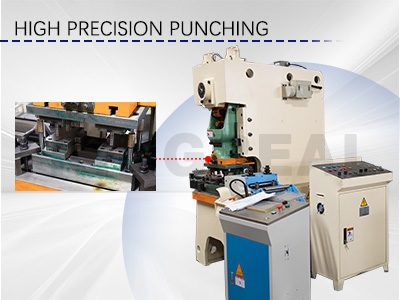

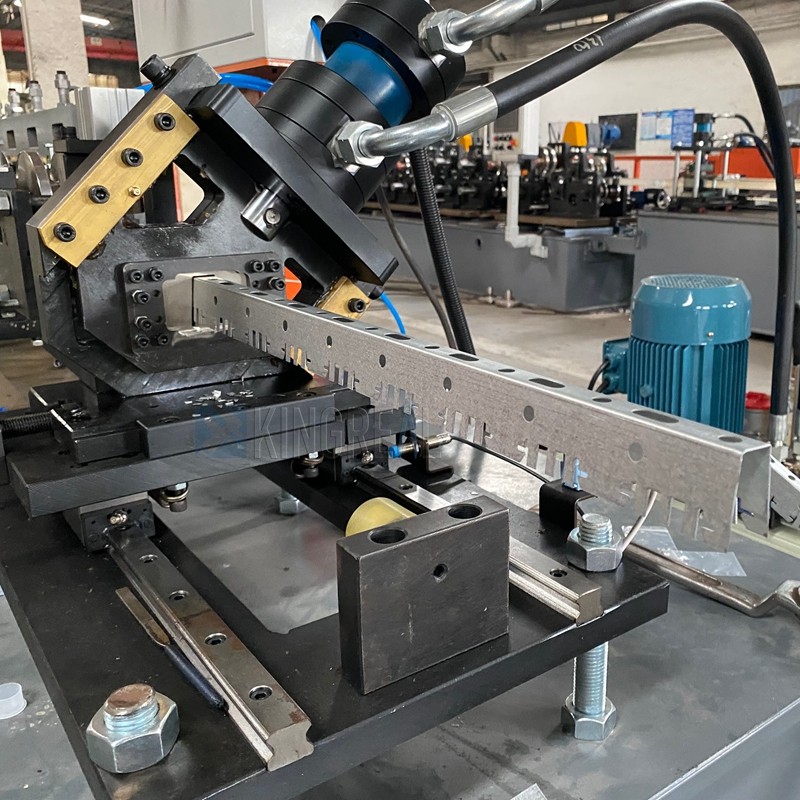

High speed punching

The metal punching machine body and punching die are made of high-hardness raw materials, which are corrosion-resistant and have a long service life. They can withstand high-speed and continuous punching operations.

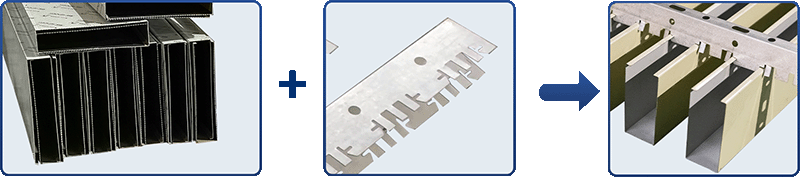

Combination With U Baffle Ceiling Making Machine

Combination baffle ceiling making machine and u baffle ceiling carrier roll forming machine to use is the choice of most u baffle ceiling manufacturers, which is conducive to improving the consistency of finished metal baffle ceiling. KINGREAL CEILING MACHINERY U Baffle Ceiling Making Machine can produce different height of metal baffle ceiling, including 150mm / 200mm / 300mm, other sizes can be customized.

Main Components of the Baffle Ceiling Carrier Machine

KINGREAL CEILING MACHINERY's baffle ceiling carrier machine is well designed and fully functional, meeting the needs of different customers. The following are the main components of the baffle ceiling carrier machine and their functions.

2-in-1 decoiler and leveling machine

The 2-in-1 decoiler and leveling machine is the first process of the baffle ceiling carrier machine which unwinds and levels the metal coil. The design of this equipment has dual functions, which can both uncoil and level, saving space and labor costs. The hydraulic system of the decoiler can ensure that the coil remains stable when unrolling to avoid deformation or damage. The leveling process effectively removes the corrugation and curvature of the coil through the interaction of multiple rollers, so that it reaches the best state when entering the subsequent processing link. The flattened metal coil will have higher processing accuracy, laying a good foundation for subsequent forming and shearing.

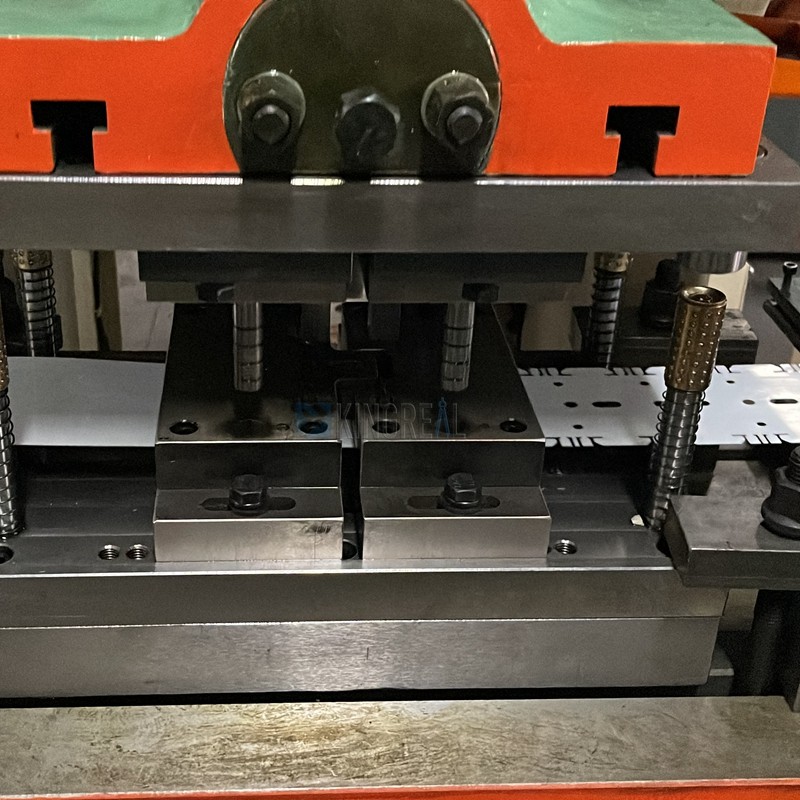

Punching Station

The punching station is a vital component of the baffle ceiling carrier machine. KINGREAL CEILING MACHINERY customizes punching dies according to the drawings provided by customers, which can punch the required holes on the metal coils. These holes are usually designed for installation and connection, ensuring a solid combination between the baffle ceiling carrier and other components. The efficiency and precision of the punching station ensure that the position and size of each hole can be processed strictly according to the customer's requirements, avoiding human errors and improving overall production efficiency.

Roll forming machine

The roll forming machine is one of the core components of the baffle ceiling carrier machine. It rolls the metal coil through a series of high-quality rollers to form the specific shape of the baffle ceiling carrier. The design of the roll forming machine ensures the efficiency and consistency of the forming process, which can meet the production needs of baffle ceiling carriers of different types and specifications. KINGREAL CEILING MACHINERY's roll forming machines are made of high-quality materials, with high strength and durability, and can withstand long-term continuous work. The precision of the roll forming machine directly affects the quality of the finished product, so it is crucial to choose a high-quality baffle ceiling carrier machine.

Shearing station

The shearing station is the last key link of the baffle ceiling carrier machine. The intelligent shearing station can automatically cut the baffle ceiling carrier according to the customer's preset length, ensuring the accuracy and smoothness of the cutting. Through the advanced control system, the shearing station can complete the cutting task quickly and accurately, avoiding the errors and burrs caused by traditional manual cutting. The efficient performance of this equipment significantly increases the production speed, reduces the need for manual intervention, and ensures that the size of each baffle ceiling carrier can meet the specific requirements of the customer.

Complete Baffle Ceiling Solution

In order to meet the diverse market needs, KINGREAL CEILING MACHINERY also provides baffle ceiling roll forming machines, which can produce baffle ceilings of different types and sizes, such as U-shaped baffle ceilings, V-shaped baffle ceilings, and U-shaped baffle ceilings with u-bent.

The baffle ceiling carrier machine and baffle ceiling machine provided by KINGREAL CEILING MACHINERY ensure a perfect match between the two, and customers no longer need to look for multiple manufacturers. This integrated solution simplifies the procurement process, allowing customers to obtain the required equipment in a more efficient way. At the same time, KINGREAL CEILING MACHINERY's professional team will provide customers with a full range of technical support and services to ensure the smooth operation of the equipment.

The combination of baffle ceiling carrier and baffle ceiling not only improves the aesthetics of the overall ceiling, but also enhances the stability and load-bearing capacity of the structure. Through reasonable design and combination, customers can achieve higher space utilization and better decorative effects.

Video About Ceiling Carrier Machine

Quality Assurance

※ Establish a strict quality system

In order to better control the quality of the Baffle Ceiling Carrier Roll Forming Machine, KINGREAL CEILING MACHINERY has established its own factory and technical team. KINGREAL CEILING MACHINERY has established standardized work process standards to ensure that the machine maintains a high standard from manufacturing to debugging. From the selection of parts to the debugging of the machine, KINGREAL CEILING MACHINERY team works strictly in accordance with the standards. To provide customers with professional and high-quality machines, in order to fulfill this promise, KINGREAL CEILING MACHINERY has subdivided the work into every step.

※ Establishing KINGREAL CEILING MACHINERY Factory

In order to better integrate R&D and manufacturing, KINGREAL CEILING MACHINERY has established its own factory. KINGREAL CEILING MACHINERY welcomes friends to visit our factory and see every step of our production. KINGREAL CEILING MACHINERY is looking forward to establishing a long-term and stable cooperative relationship with friends.

Get the latest price? We'll respond as soon as possible(within 12 hours)