How do you perforate metal sheets?

2024-12-05 17:33

Video About Metal Sheet Perforated Machine

Introduction to Metal Sheet Perforated Machine

Metal sheet perforation technology occupies an important position in industrial manufacturing, architectural design and home decoration, and is widely used in ventilation systems, screening equipment, decorative structures and other aspects. In this processing process, the metal sheet perforated machine as an efficient and precise key equipment has greatly promoted the development of the industry. This article will introduce in detail the process of metal sheet perforated machine, the structure and advantages of the metal sheet perforated machine, the practical application and its future development direction, and fully demonstrate the core role of the metal sheet perforation machine. |  |

Basic Overview of Metal Sheet Perforation

1. Definition and Function of Perforation

Metal sheet perforation machine forms regular or irregular holes on the surface of metal sheets through mechanical or other process means. Its main functions include:

※Functionality:Improve ventilation and heat dissipation performance, used for filtering, sound insulation and shading.

※Aesthetics:Improve the decorative effect by designing specific patterns, and is widely used in building curtain walls, home decoration and other fields.

※Practicality:Used to make functional components such as sifters and filters.

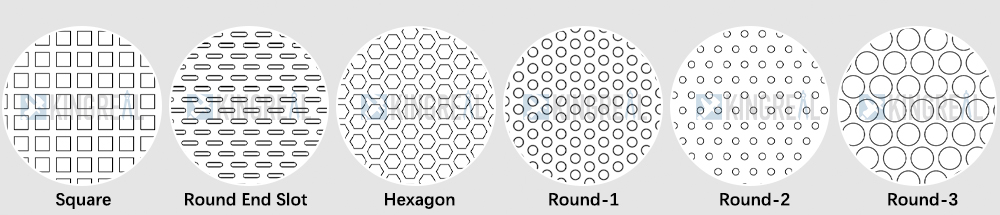

2. Common perforation patterns

The perforation pattern depends on the application requirements. Common shapes include: round, square, oval, hexagonal, and more complex custom patterns such as waves and stars.

Traditional methods and limitations of metal plate perforation process

Traditional metal plate perforation methods mainly include:

※Manual punching:suitable for small batch and personalized processing, but low efficiency and difficult to ensure accuracy.

※Stamping die processing: batch perforation through fixed die, high production efficiency, but limited by the flexibility of die design.

※Laser cutting: complex patterns can be achieved, but the equipment cost is high and the processing speed is slow.

These traditional methods have met the early needs to a certain extent, but there are deficiencies in accuracy, efficiency and cost control. With the improvement of market requirements for perforation technology, the application of sheet perforation machines has gradually become popular.

Core role and technical advantages of sheet perforation machines

Metal perforated making machines are automated equipment designed for metal plate perforation. They use advanced mechanical and CNC technology and can efficiently complete large-scale processing tasks. The following are the detailed advantages of the perforated punching machine:

1. High-precision processing

The metal perforated making machine relies on high-quality molds and precision control systems to achieve consistency in hole diameter and hole spacing, greatly reducing the error rate and meeting high-demand industrial standards.

2. Fast production capacity

Modern metal perforated making machines can complete hundreds of punching operations per minute, greatly improving production efficiency, and are particularly suitable for mass production needs.

3. Diversified design support

The metal perforated making machine can process hole patterns of various shapes, support users to customize complex patterns, and provide more possibilities for product design.

4. Automation and intelligence

The metal perforated making machine equipped with a CNC (computer numerical control) system can realize automated operation through programming, including feeding, punching, waste discharge and other steps, greatly reducing dependence on manual labor.

5. Compatible with a variety of materials

The metal materials that can be processed by the metal perforated making machine include stainless steel, aluminum, copper and carbon steel, etc., and the application field is very wide.

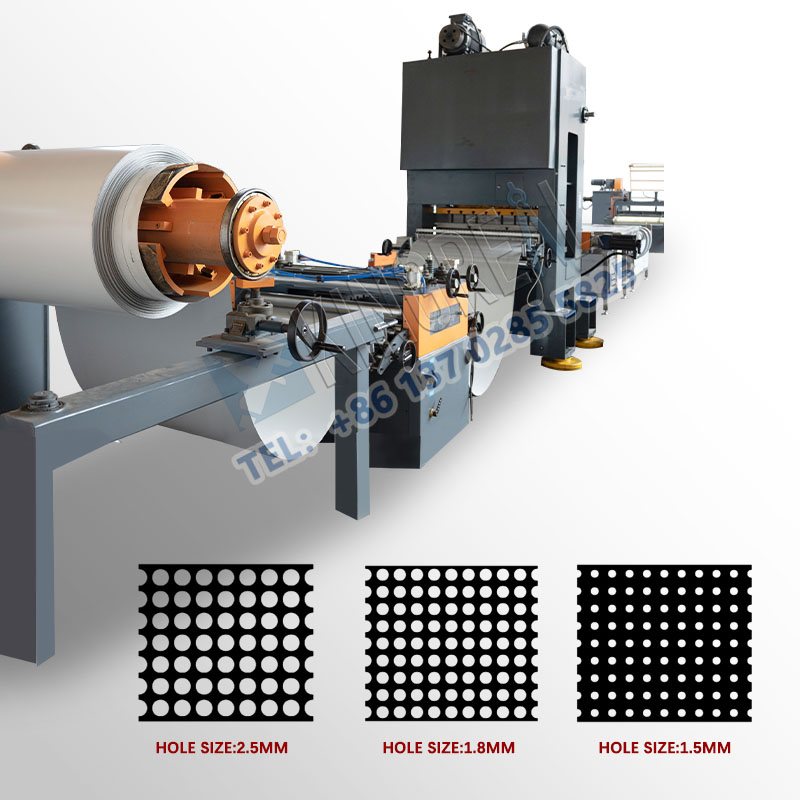

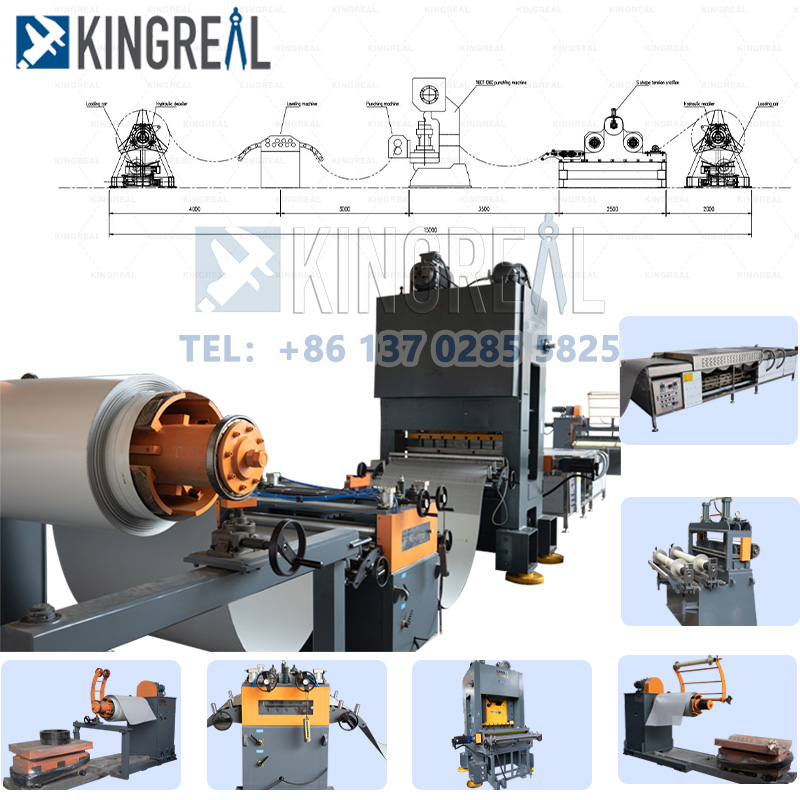

Structure and Working Principle of Metal Perforated Making Machine

1. Main components of metal perforated making machine ※Punching system for metal perforated making machine: including main frame, punch and die, responsible for punching operation. ※Feeding device for metal perforated making machine: used for precise positioning and continuous feeding to ensure efficient production. ※Control system for metal perforated making machine: CNC system provides programming support for pattern design and operating parameters. ※Waste handling system for metal perforated making machine: collects waste generated during the punching process for easy cleaning and recycling. 2. Working principle of metal perforated making machine The metal perforated making machineapplies vertical pressure to the metal plate through the cooperation of the die and punch, punching out holes in part of the plate. The feeding system is responsible for moving the metal plate according to the set rhythm to ensure the precise arrangement between the holes. |  |

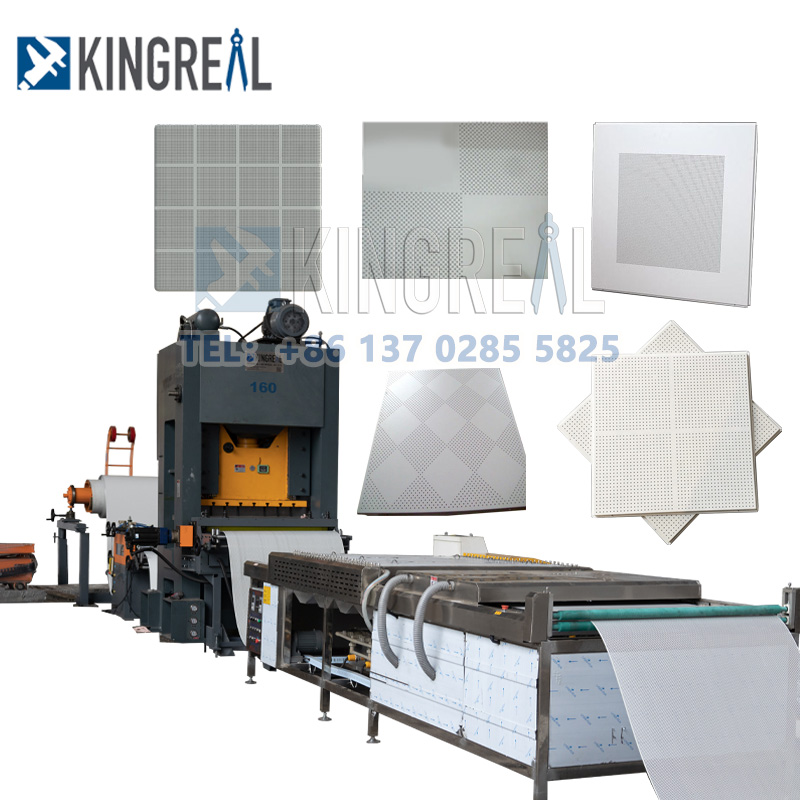

Application of Metal Perforated Making Machine

| 1. Metal perforated making machine in construction field Punching metal plate has a wide range of uses in architectural decoration, such as: ※Curtain wall decoration: adds a modern feel to the facade of the building, while also having ventilation and insulation functions. ※Sound-absorbing wall: In indoor applications, perforated plates combined with sound-absorbing materials can significantly improve the acoustic environment.

|  |

2. Metal perforated making machine in industrial manufacturing Metal plates manufactured by metal perforated making machines are widely used in: ※Screening equipment: such as key components in industries such as ore screening and grain separation. ※Ventilation systems: used in industrial equipment and vehicle vents.

3. Metal perforated making machine in home decoration The application of perforated plates in furniture manufacturing includes: ※Lampshades: creating artistic lighting effects through unique hole design. ※Furniture components: such as table and chair surfaces and decorative screens. |  |

Economic and environmental value of sheet punching machines

1. Cost control

※Reduce labor costs: The automation characteristics of perforated punching machines reduce dependence on highly skilled labor.

※Optimize material utilization: High-precision perforation processing reduces the proportion of waste.

2. Environmental benefits

※The sheet punching machine adopts an energy-saving drive system to reduce energy consumption.

※The waste recycling system facilitates the reuse of scraps and reduces resource waste.

Development Trends and Prospects of Metal Perforated Making Machine

1. Intelligent Upgrade Future metal perforated making machines will further integrate artificial intelligence technology to optimize processing efficiency through real-time monitoring and adjustment.

2. Multi-functionality The new generation of metal perforated making machines may integrate multiple metal processing functions, such as bending, cutting and surface treatment, to provide a one-stop solution.

3. Sustainable Development Under the general trend of green manufacturing, metal perforated making machines will pay more attention to energy efficiency and environmental protection performance, and promote the industry to move towards a low-carbon economy. |  |

Conclusion

Metal plate perforation technology occupies an important position in modern industry, and metal perforated making machines are the core tools for the efficient implementation of this technology. With its high precision, diversity and environmental protection performance, metal perforated making machines not only improve the efficiency and quality of metal processing, but also provide more possibilities for the design and manufacturing fields.

With the continuous development of technology, metal perforated making machines will continue to lead the innovation of metal plate perforation technology in the future and promote the industry to a more intelligent and sustainable future.

Whether it is mass production or personalized design, the metal perforated making machine is undoubtedly the best choice for metal plate perforation processing.

Get the latest price? We'll respond as soon as possible(within 12 hours)