What is the purpose of a perforated ceiling?

2024-12-03 14:28

Perforated ceiling tile is one of the important parts of interior decoration. It refers to the decoration of the top of the house living environment. In simple terms, it is the decoration of the ceiling. Perforated ceiling tile has multiple functions such as heat preservation, heat insulation, sound insulation, sound absorption, etc. It is also a hidden layer for electrical, ventilation and air conditioning, communication and fire protection, alarm pipeline equipment and other projects.

Functions of perforated ceiling

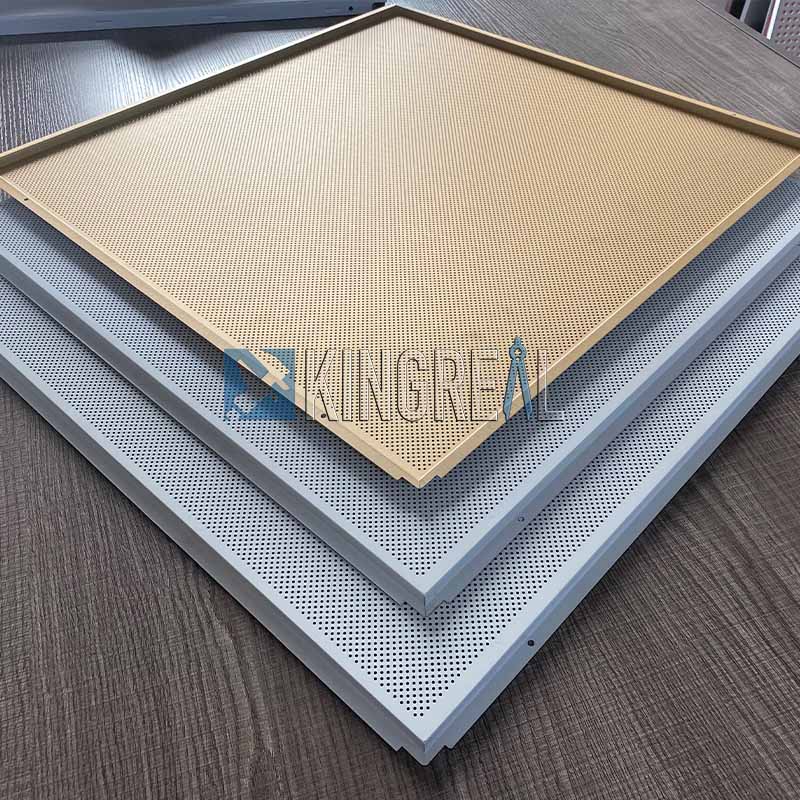

1.The metal perforated ceiling tile is a metal material that is perforated with a certain aperture by perforated sheet making machine and density and then pressed into various shapes by metal ceiling tile production line. It is mainly used in places with high requirements for sound absorption, such as roof bottom plates of movie theaters, stadiums, libraries, etc.

2.The sound-absorbing structure formed by the combination of metal perforated ceiling tile and false ceiling has the characteristics of strong overall sense and beautiful appearance. It can provide a wider sound absorption frequency band, especially for the ideal absorption effect of low-frequency noise.

3.The sound-absorbing structure that combines the sound-absorbing perforated ceiling tile and the wall has a strong overall sense, a luxurious appearance, a wide sound-absorbing frequency band, and is particularly suitable for absorbing low-frequency environmental noise.

Video About Metal Sheet Perforation Line

Working principle of perforated ceiling

1. Sound absorption is the phenomenon of energy loss after sound waves hit the surface of perforated ceiling tile. It can reduce the indoor sound pressure level and reduce noise pollution.

2. The sound absorption materials of perforated ceiling tile include centrifugal glass wool, rock wool, mineral wool, plant fiber spray, etc. These materials contain a large number of tiny pores inside, and sound waves penetrate into the material along these pores, rub against the material, and convert sound energy into heat energy.

3. Even if the sound absorption performance of the perforated ceiling material itself is not good, the structure itself has certain sound absorption performance. For example, perforated gypsum board, wood board, metal plate, etc., they absorb sound energy through mechanisms such as Helmholtz resonance, film or thin plate resonance.

Production process of perforated ceiling

Step 1:material cutting - leveling

Material cutting: Send the raw matal coil or metal plate to the metal coil slitter or cut to length machine for sheet metal slitting or cutting as required width. And the stacked or rewinded them.

Leveling: Use a leveling machine to straighten the metal coil and then send it to the next process.

Step 2: Punching - Notching and shearing - Forming

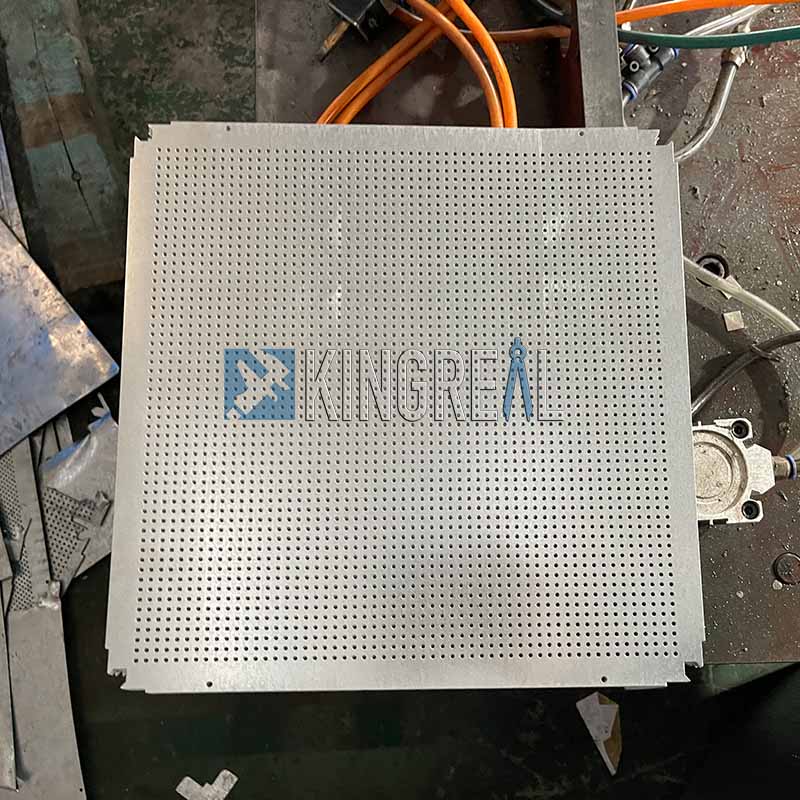

Punching: Use perforated punching machine to complete the perforated sheet metal requirements;

Notching and shearing: The design of the metal ceiling panel notching and shearing must be very precise, and the corner cutting must be in place when cutting, otherwise the intersection angle between the ceiling boards will be uneven when the false ceiling is hoisted;

Forming: Send the metal plate to the perforated punching machine and use the mold to press and form.

Step 3: Stick and dry the non-woven

Stick and dry the non-woven: The aluminium perforated ceiling tiles need to be sticked with dust proof and sound fleece by Acoustic Fleece Sticking Machine. The sound fleece sticking by glue and has a certain humidity, so it needs to be dried by the drying oven in the acoustic fleece sticking machine.

Step 4: Inspection-packing

Inspection: The finished perforated ceiling tile inspection should check the paint quality, flatness, and dimensional error. This link is the most important. Quality inspectors are specially arranged to conduct strict perforated ceiling tile inspections to completely eliminate unqualified products;

Packing: The perforated ceiling tiles that are completely qualified and have no quality defects are packed and then put into storage.

Get the latest price? We'll respond as soon as possible(within 12 hours)