What kind of metal is the ceiling made of?

2024-12-02 11:58

The ceiling is an indispensable part of modern architecture, which not only plays a beautiful and decorative role, but also needs to have certain functions, such as sound insulation, heat insulation, fire prevention and so on. With the development of building materials, metal ceilings have gradually become the material of choice in many commercial and industrial buildings.

For projects with high requirements for quality and aesthetics, metal ceilings can provide a modern design while also meeting the needs of durability and functionality. So what kind of metal is the ceiling made of? How do we process these materials through the metal ceiling production line?

The type of metal commonly used in ceilings

1. Aluminum alloy

Aluminum ceiling is widely used in modern architecture because of its light weight, corrosion resistance and excellent plasticity. The surface of the aluminum alloy ceiling can be treated in various ways, such as spraying, oxidation, drawing, etc., to meet the needs of different design styles and decorative effects. Aluminum ceiling not only has a modern appearance, but also has a good oxidation resistance, suitable for long-term use and easy maintenance.

2. Steel

Steel is one of the most widely used metals in the construction industry, and steel ceilings have extremely high strength and durability to meet the requirements of high-intensity environments. Although the steel itself may be affected by oxidation, the steel ceiling treated with an anti-corrosion coating can effectively avoid rust and extend the service life. The steel ceiling has a low cost and is suitable for large area and standardized construction needs.

3. Stainless Steel

Stainless steel ceiling with its high corrosion resistance and high strength characteristics, widely used in high-end buildings and special requirements of the environment, such as hospitals, laboratories, etc. They often have a mirror-gloss appearance that adds a modern feel to a space. Although stainless steel ceilings cost more, their excellent durability and aesthetics make them very popular in some high-end projects.

4. Copper alloy

Copper alloy ceiling with its special color and excellent electrical conductivity, often used in some occasions that require unique decorative effects. Copper alloy ceilings can gradually oxidize over time, showing a unique color change, which also makes copper ceilings in some special designs have a unique charm. Although the cost is higher, its unique appearance and material characteristics make it a place in high-end decoration.

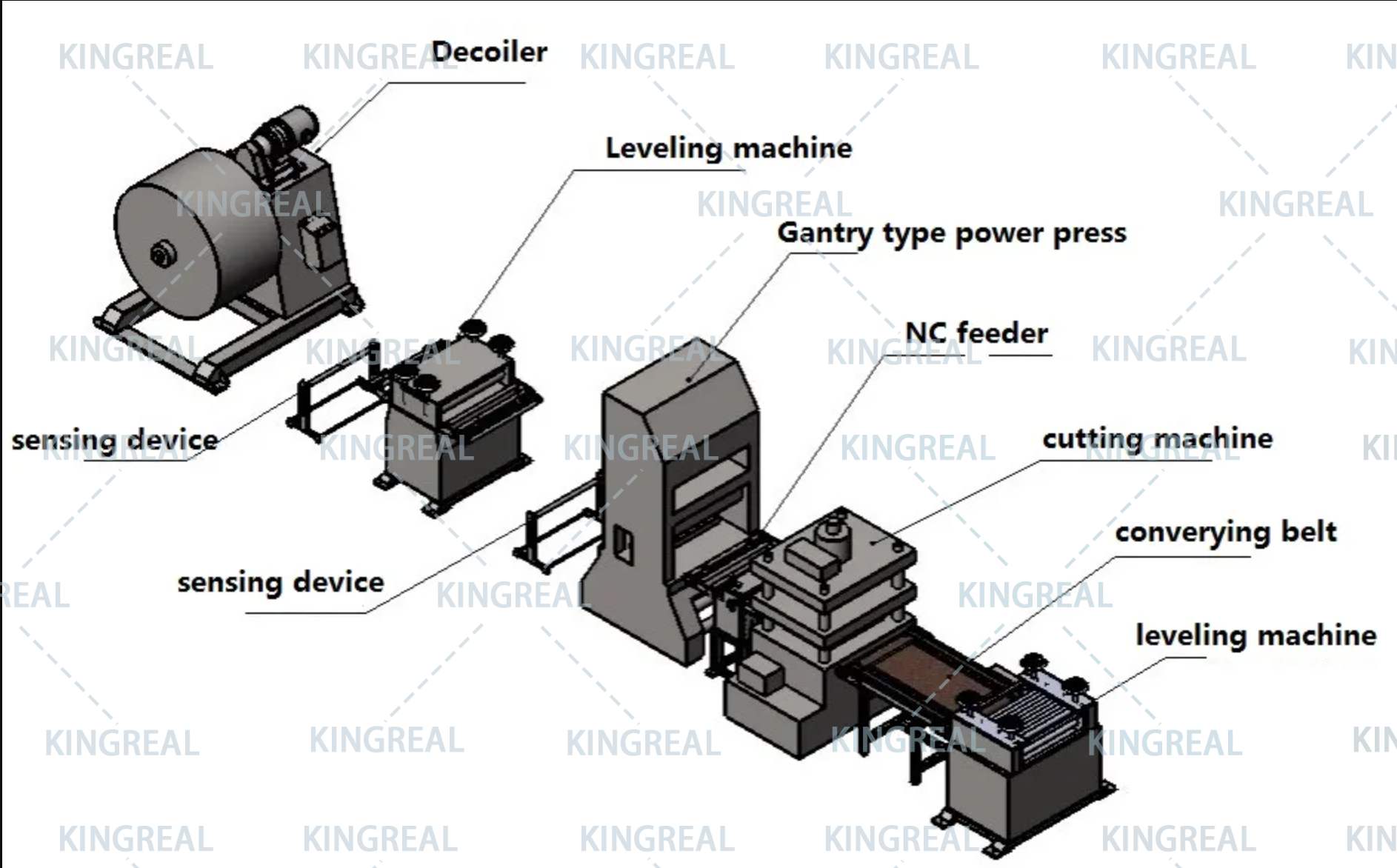

Features of false ceiling machine

The production of metal ceilings not only depends on the choice of raw materials, but also needs to be processed by professional metal ceiling production lines. At this time, the role of the metal ceiling production line is particularly important. False ceiling machine is a set of automatic equipment specially used for metal ceiling processing, it can be different metal materials, such as aluminum, steel, stainless steel, etc., through a series of precision machining, to produce metal ceilings that meet the specifications.

Main process flow

1. Supply and treatment of metal coils

The first step in the metal ceiling production line is to feed the metal coil into the production line. Usually these coils are cut and trimmed before proceeding to the next stage of processing. In this process, the false ceiling machine will smooth and stretch the metal coil to ensure that the metal sheet has no defects and has good surface quality.

2. Stamping and modeling

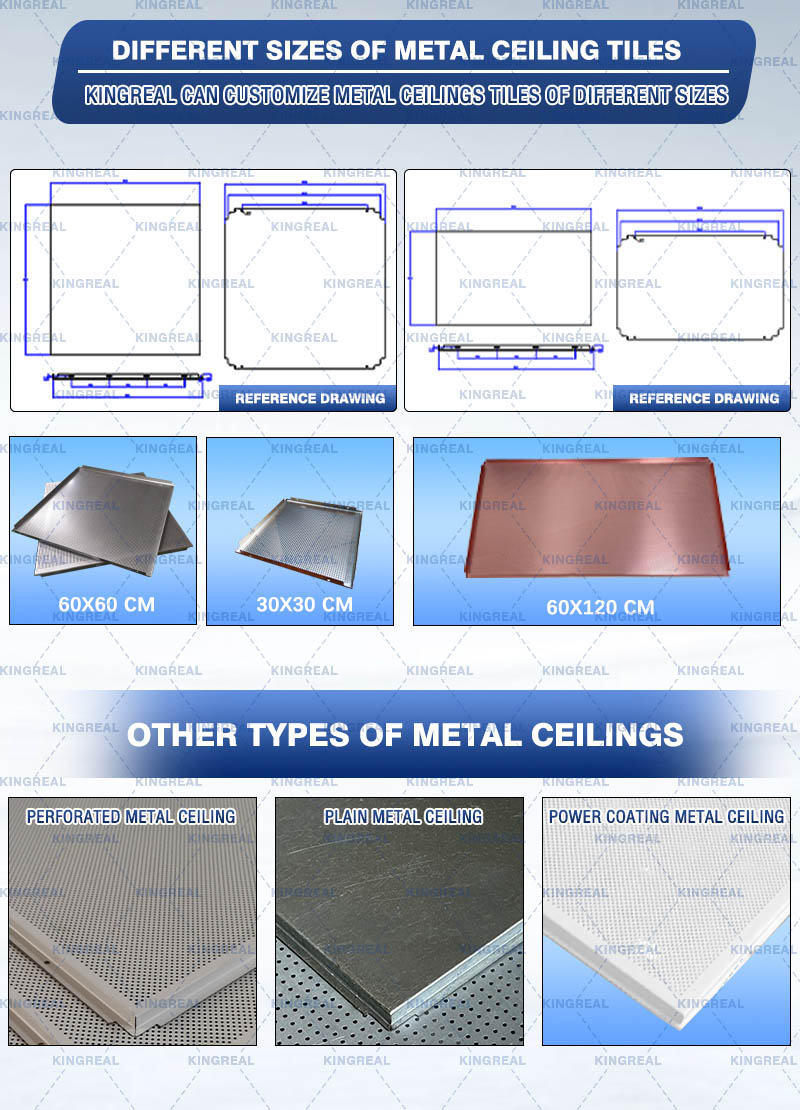

Metal ceiling production lines are usually equipped with punching machines, bending machines and other equipment for processing sheet metal into various shapes of ceiling panels. Whether it is flat, curved, or with a special pattern of the ceiling, the mold and stamping equipment on the production line can accurately process the design requirements.

3. Surface treatment

The appearance requirements of the metal ceiling are very high, and the surface treatment link on the metal ceiling production line is particularly important. Common surface treatment processes include spraying, coating, oxidation, wire drawing, etc. These processes can not only enhance the beauty of metal ceilings, but also enhance their corrosion resistance and wear resistance.

4. Cutting and shaping

After the surface treatment of the metal sheet will enter the cutting and shaping link, the cutting machine on the metal ceiling production line, the shearing machine and other equipment will be according to the requirements of the product design, the metal ceiling will be cut into the required size and shape. Each piece of ceiling will be finished under strict workmanship standards to ensure the quality of each product.

5. Assembly and packaging

Finally, the false ceiling machine will complete the assembly and packaging of the metal ceiling. The certified ceiling panels will be packaged and ready for delivery to the customer site. Automated packaging processes can increase production efficiency and reduce errors caused by human operation.

How to choose metal material?

When selecting the metal material of the ceiling, in addition to considering the appearance and decorative effect, it should also consider its functional requirements, such as fire resistance, corrosion resistance, strength and weight. Different types of metal materials have different processing difficulties in the metal ceiling production line, so when selecting materials, the balance of production process and cost should also be taken into account.

Sum up

There are many kinds of metal materials used in the ceiling, aluminum alloy, steel, stainless steel and copper alloy can be selected according to different building needs. The metal ceiling production line plays a crucial role in the processing of these metal materials. Through efficient and sophisticated equipment, the false ceiling machine ensures the quality and appearance of the ceiling to meet the diverse needs of ceilings in modern buildings. When choosing metal materials, we should not only pay attention to their beauty and functionality, but also consider the adaptation of production costs and processing processes.

Get the latest price? We'll respond as soon as possible(within 12 hours)