How to manufacture metal ceiling tiles?

2024-11-29 11:11

No good product comes into existence easily, its production involves a challenging process. In everyday life, we often only see the finished results of many products, while the production process behind them remains unclear. So, what is the manufacturing process for metal ceiling tiles? How are false ceiling panels made? Let's explore this together!

The production of metal ceiling tiles requires metal ceiling tile machines, also known as metal ceiling panel production line.

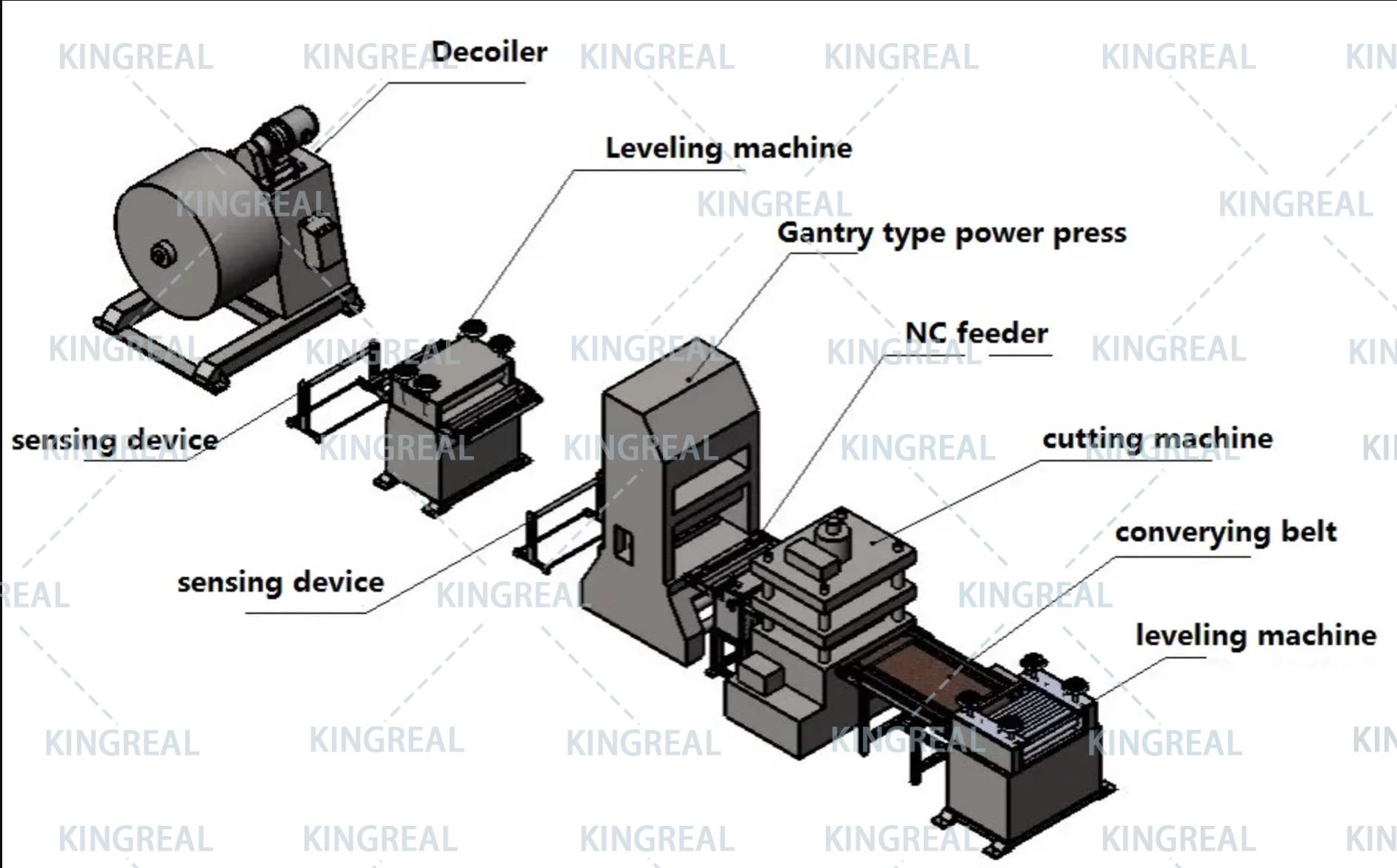

Components of ceiling panel production line

A metal ceiling panel production line consists of an decoiler, a pre-straightener, a punching machine, an NC servo feeder, a hydraulic notcher and shearer, a conveyor, a precision straightener, an automatic tile flipper, an automatic feeding robotic arm, a hydraulic bending machine, and an electrical control system.

Workflow of metal ceiling tile machine

The process begins with placing the metal raw materials on the decoiler. The decoiler then unfolds the coiled material and feeds it forward to the leveling machine. Once the material reaches the leveling machine, it is flattened to ensure a smooth surface. The flattened material is then fed into the punching machine, where it is punched. The punched material is conveyed to the first conveyor by the feeder. The first conveyor then moves it to the shearing machine, which cuts the material to the required dimensions. The cut material is subsequently transported to a designated collection point by the second conveyor, completing the production of the metal ceiling tiles.

Advantages of KINGREAL CEILING MACHINERY Metal Ceiling Tile Machine

1. Production of Various Sizes

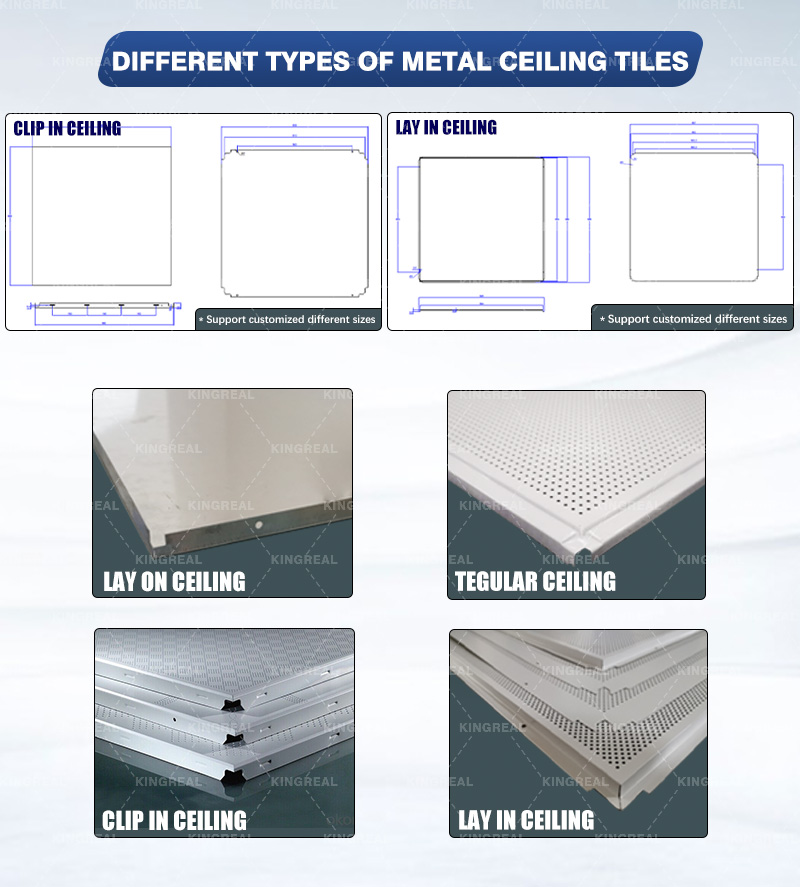

The metal ceiling tile notching mold is designed as integral design and it can produce 30*60CM metal false ceiling panel, 60*60CM metal ceiling tile and 120*60CM metal ceiling tile on the same mold. KINGREAL CEILING MACHINERY metal ceiling panel production line is featured with easy to operate, high speed output and full automatically running.

2. Automated Design Reduces Production Costs

The aluminum ceiling bending is fully automated. An automatic robotic arm feeds perforated sheets into the bending hydraulic machine and ejects the finished product from the mold. This type of metal ceiling tile machine effectively reduces machine costs and saves space, reflecting current market trends. KINGREAL CEILING MACHINERY’s hydraulic ceiling bending machine can complete the bending of metal false ceiling panels automatically, with perforated sheets being fed into the hydraulic bending machine by the robotic arm. The fully automated design of KINGREAL CEILING MACHINERY’s metal ceiling panel production lines reduces the risk of workplace injuries and lowers labor costs, which are rising rapidly in many countries.

3. Unique Hydraulic Design

The hydraulic machine performs the bending process. After the metal ceiling tile is bent, it is ejected, and a new perforated sheet is inserted into the hydraulic machine. KINGREAL CEILING MACHINERY’s hydraulic ceiling tile bending machine is a 140-ton high-capacity hydraulic machine.

4. Multiple Options Available

KINGREAL CEILING MACHINERY offers both fully automatic and semi-automatic ceiling panel production line solutions to meet different production scales and requirements. The fully automatic option is ideal for large-scale production, significantly improving efficiency and consistency, while the semi-automatic option is suitable for medium to small-scale production, offering flexibility and cost-effectiveness. Additionally, KINGREAL CEILING MACHINERY provides various auxiliary equipment, including feeding trolleys and cloth-pasting machines, which can be integrated with the metal ceiling tile machine to further optimize the production process, enhance operational convenience, and improve product quality. Whether you need efficient large-scale production or flexible medium-to-small-scale production, KINGREAL CEILING MACHINERY can provide customized solutions to fully meet your production needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)