What Is Furring Channel Making Machine?

2025-04-27 17:00

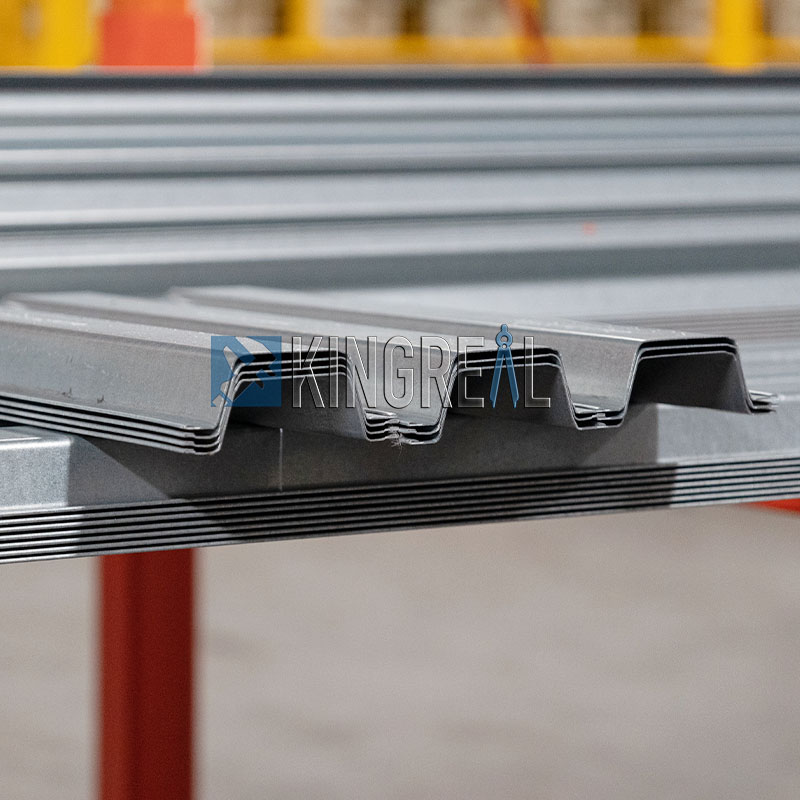

Furring channel making machine, also known as the hat channel machine or omega channel machine, is a device specifically designed for producing furring channels. These profiles are widely used in the construction industry, mainly for creating a flat surface for gypsum boards and other finishing materials. Through the work processes of unwinding, forming, cutting and discharging, KINGREAL CEILING MACHINERY furring channel making machines can efficiently produce high-quality furring channels of different sizes to meet the diverse needs of the market.

Advantages of Furring Channel Making Machines

KINGREAL CEILING MACHINERY is a professional hat channel machine manufacturer with rich experience in design, R&D and sales. Currently, KINGREAL CEILING MACHINERY false ceiling channel machines have been sold to Saudi Arabia, India, Egypt, Qatar, UAE, Turkey and other countries. KINGREAL CEILING MACHINERY engineers have a deep understanding of the differences in furring channel making machine parameters in various countries, and customize the design according to the specific production conditions of customers to meet needs.

Choosing KINGREAL CEILING MACHINERY hat channel machines can not only improve production efficiency but also ensure product quality. Its main advantages include:

Efficiency

With advanced automation technology and streamlined process flow, KINGREAL CEILING MACHINERY hat channel machines are extremely efficient and can produce quickly without affecting quality. The furring channel making machine is equipped with an intelligent touch screen. Users only need to enter the adjustment parameters on the screen, and the hat channel machine will automatically run according to the instructions, which is easy to operate.

Versatility

The furring channel making machine has a wide range of uses and can produce furring channels of various sizes (by adjusting roller groups) to meet diverse construction needs. This flexibility allows users to quickly adjust production strategies according to market changes and customer needs.

Protective shield

In order to protect the safety of workers, KINGREAL CEILING MACHINERY has equipped the hat channel machine with a protective shield. This design not only prevents accidental injuries during operation, but also improves the safety of the working environment and ensures the safety of the staff.

High precision

The furring channel making machine is composed of precision components and can achieve high-precision forming and shearing. In particular, the following cutting system adopted in the cutting station allows the shearing process to be processed without stopping the hat channel machine, ensuring that the produced hat channels have high precision and meet the customer's strict requirements for details.

Customer Needs of Purchasing Hat Channel Machines

In actual applications, customers who purchase furring channel making machines often consider the selection of supporting equipment. When purchasing a hat channel machine, many customers usually purchase an u channel machine and a wall angle profile machine at the same time to form a complete production system. This combination not only improves production efficiency, but also further meets the diverse market needs.

The u channel machine has a similar working principle to the furring channel making machine and can produce u channels. The wall angle machine is used to produce wall angle profiles. Usually, the hat channel machine, u channel machine and wall angle profile machine are used together to form a complete system. This combination allows customers to obtain multiple profiles at the same time during construction, simplifying the procurement process and reducing operating costs.

Application Areas of Furring Channel Making Machines

The finished products produced by hat channel machines are mainly used in construction, especially when dealing with gypsum boards and other finishing materials, providing a flat foundation. The following are the main application areas of furring channel making machines:

1. Surface leveling

Hat channels are used to level irregular surfaces such as masonry, concrete walls and ceilings. By installing hat channels on uneven substrates, the irregularities of the substrate can be effectively hidden, providing a smooth surface for subsequent decoration work.

2. Hiding utilities

Hat channels can leave space for wires, pipes and other utilities without moving materials. This allows for more flexible design arrangements when carrying out construction, keeping the space neat and beautiful.

3. Providing thermal insulation and acoustic performance

Furring channels are not only structural support, but also leave cavity space for thermal insulation and service facilities. The presence of this cavity helps to improve the acoustic performance of walls and ceilings and enhance the overall comfort of the building.

4. Material selection

Hat channels are generally made of high-quality galvanized steel with excellent corrosion and deformation resistance. This ensures long-term reliability in various environments, especially in humid or harsh environments, where the hat channels can still maintain their performance.

Market Prospects of Furring Channel Making Machine

With the continuous development of the construction industry, the demand for hat channels is increasing. Especially in modern buildings, it has become a trend to use hat channels to improve construction efficiency and product quality. With the improvement of people's requirements for the beauty and comfort of buildings, the market prospects of hat channel machines are broad.

1. Growth of market demand

In recent years, with the acceleration of urbanization and the increase in infrastructure construction, the construction industry has flourished. The demand for high-quality building materials has risen accordingly, and the market demand for furring channel making machines as key production equipment has also been increasing.

2. Driven by technological progress

The advancement of science and technology has promoted the technological upgrading of furring channel making machines, which has significantly improved production efficiency and product quality. In the future, with the further development of intelligent manufacturing and automation technology, the application field of hat channel machines will be more extensive.

3. Environmental protection and sustainable development

In today's construction industry, environmental protection and sustainable development have become important issues. The profiles produced by the furring channel making machine meet the requirements of modern construction for environmentally friendly materials due to their durability and recyclability, further promoting the growth of its market.

Get the latest price? We'll respond as soon as possible(within 12 hours)