Why do we need a sheet straightening machine?

2025-03-28 17:00

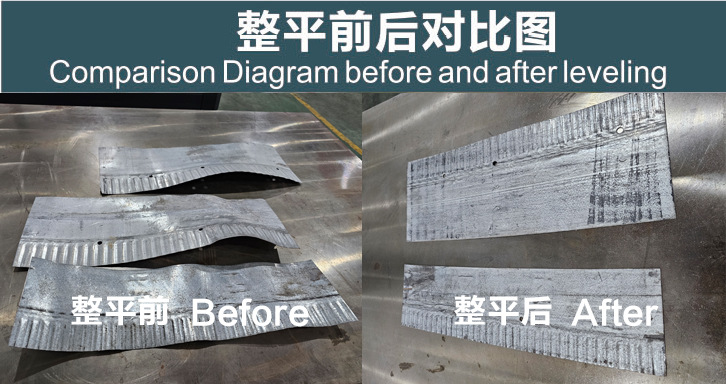

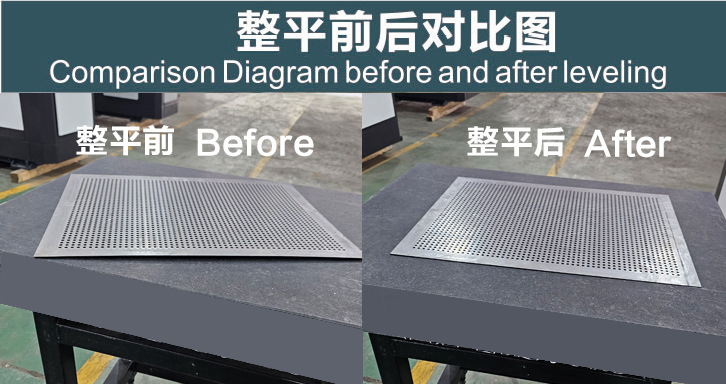

The sheet straightening machine is an important mechanical equipment widely used in the metal processing industry. Its working principle is to put metal objects into the sheet metal straightener, and through a series of staggered leveling rollers, perform multiple positive and reverse bends, thereby reducing the original curvature and alternating bending degree of the material, and finally achieve a reliable leveling effect.

Metal sheet straightening machines play an indispensable role in modern manufacturing. With the advancement of science and technology and changes in market demand, the technology of sheet metal straighteners is constantly innovating, and the application field is also constantly expanding. The efficiency, precision and labor cost saving advantages of metal sheet straightening machines make it an indispensable and important equipment in the production process of various industries. In this article, KINGREAL CEILING MACHINERY will discuss in detail with you the function, application, necessity and position of sheet metal straighteners in the global market.

1. Working principle of sheet straightening machine

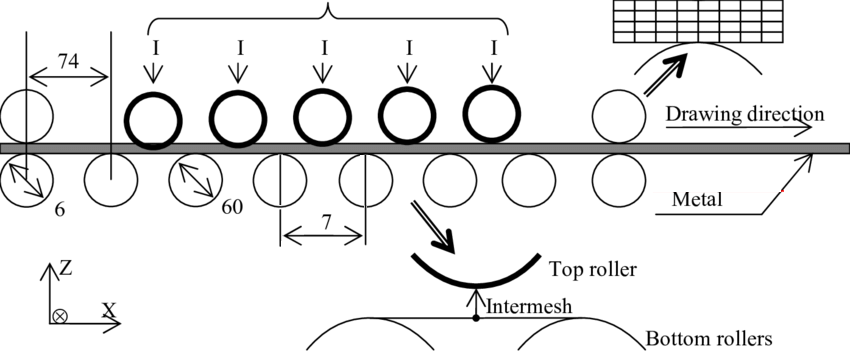

The core of the metal sheet straightening machine is the design of its leveling rollers. These rollers are staggered up and down, and when the material passes through these rollers, it will undergo a series of bends. The function of this bending is to gradually reduce the curvature of metal sheets or other metal materials, making their surface smoother. During the operation of the sheet metal straightener, the material moves between the rollers and is subjected to continuous pressure and stretching. This process achieves the leveling of the material.

1.1 Structure of the metal sheet straightening machine

The sheet metal straightener usually consists of the following parts:

- Feeding port: used to place the metal material to be leveled.

- Leveling roller: This is the core part of the sheet straightening machine, which is leveled in an up and down staggered manner.

- Discharge port: After leveling, the material is discharged through this port.

2. Application scope of the sheet metal straightener

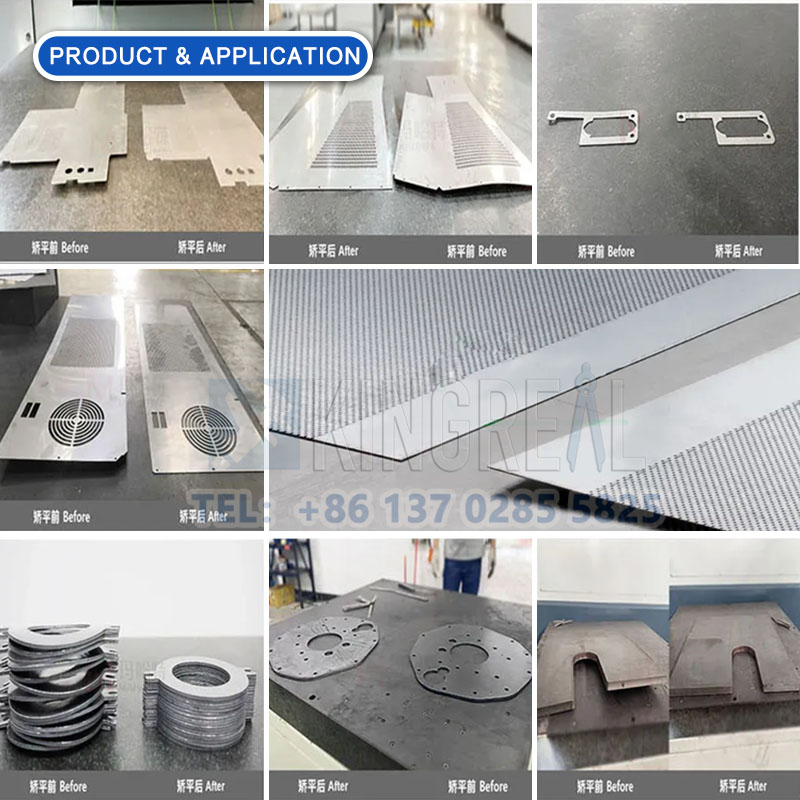

Metal sheet straightening machines are widely used for the leveling of various metal materials, including but not limited to the following:

- Metal parts: such as parts of automobiles, aircraft, etc., which require high surface flatness.

- Metal sheets: used in construction, manufacturing and other industries, commonly found in steel, aluminum, etc.

- Metal mesh: used in construction, agriculture and other fields.

- Metal rods: such as steel bars, etc., need to ensure straightness and surface flatness.

3. Reasons for needing a sheet metal straightener

With the advancement of modernization, the importance of metal sheet straightening machines has become increasingly prominent. The following points are the main reasons why we need a sheet straightening machine:

3.1 Improve efficiency

In modern industrial production, efficiency is an important part of corporate competitiveness. The use of a metal sheet straightening machine can greatly improve the leveling efficiency and ensure that a large number of leveling tasks are completed in a short time. This is especially important for companies pursuing efficient production, and can help companies respond quickly to market demand.

3.2 Improve precision

With the development of science and technology, the requirements for product quality are constantly increasing. Traditional manual leveling can no longer meet the accuracy requirements of modern production. Leveling machines can provide higher leveling accuracy to ensure that the final product meets strict quality standards. Therefore, sheet metal straighteners have gradually replaced traditional leveling methods in modern manufacturing.

3.3 Reduce cost of time and labor

The leveling machine has a high degree of automation and can complete a large number of leveling tasks in a short time. This not only saves production time, but also reduces dependence on labor and reduces labor costs. Enterprises can invest more resources in other more valuable links, thereby improving overall production efficiency.

3.4 Demand in all industries

The flattening of metal materials is a necessary step in the production process of many industries. Whether it is automobile manufacturing, construction, or home appliance production, flattened metal materials are important raw materials. The existence of sheet straightening machines ensures that all industries can obtain qualified raw materials, thereby ensuring the quality of the final product.

4. Application market of metal sheet straightening machines

The application market of metal sheet straightening machinesis all over the world. The following is a market analysis of five major countries:

4.1 China

China is one of the largest metal processing markets in the world, and the demand for sheet metal straighteners is huge. With the rapid development of the manufacturing industry, especially in the automotive and construction industries, the application of sheet straightening machines is becoming more and more extensive. China's sheet metal straightener manufacturing technology is also constantly improving, gradually developing towards high precision and high efficiency.

4.2 The United States

The United States is an important industrial power in the world, and the demand for sheet straightening machines in aerospace, automobile manufacturing and metal processing continues to grow. American companies have high technical requirements for sheet straightening machines and tend to use high-end automation equipment to improve production efficiency and product quality.

4.3 Germany

Germany is famous for its precision manufacturing, and levelers occupy an important position in its industry. German companies focus on the technological innovation of sheet metal straighteners, and many high-end metal sheet straightening machines are developed and produced in Germany. With the advancement of Industry 4.0, the intelligence and automation level of metal sheet straightening machines are also constantly improving.

4.4 Japan

Japan is another technologically advanced country, and its sheet metal straightener market is also vibrant. Japanese companies have extremely high requirements for leveling accuracy, and are also very active in technological innovation and R&D investment in sheet straightening machines. With the development of robotics technology, the automation level of levelers will be further improved.

4.5 India

India's manufacturing industry is developing rapidly, and the demand for sheet straightening machines is also rising. With the advancement of infrastructure construction, the demand for metal materials has increased significantly, and the application prospects of sheet straightening machines in the construction and automotive industries are broad. There is still a lot of room for development in India's sheet straightening machine market, which has attracted the attention of many foreign companies.

Get the latest price? We'll respond as soon as possible(within 12 hours)