How does perforated metal machine change way of production?

2025-04-23 17:00

In modern manufacturing, perforated metal machine, as an efficient production equipment, is gradually changing the traditional production methods. It not only improves production efficiency, but also improves product quality and meets diversified market needs. In this article, KINGREAL CEILING MACHINERY will discuss more about the steel perforated machine with you.

Background of People Using Sheet Metal Perforation Machine

In many industries, users of steel perforated machines mainly include enterprises that need to perform secondary processing on metal sheets or metal coils. These enterprises usually involve multiple fields such as construction, automobile manufacturing, home appliance production, mechanical processing, etc. Their products include but are not limited to:

Perforated screen: widely used in mining, chemical and food industries as a key part of filtration and separation.

Perforated bread tray: In the food industry, it is used to make trays for baked products to ensure uniform heating and exhaust.

Perforated chair: In the furniture industry, the perforated design not only provides beauty, but also reduces the use of materials and improves lightness.

Perforated muffler: In automobiles and mechanical equipment, the perforated muffler effectively reduces noise through its aperture design.

Perforated wall panels: In the construction industry, perforated wall panels are not only used for structural support, but also as architectural decoration to enhance aesthetics.

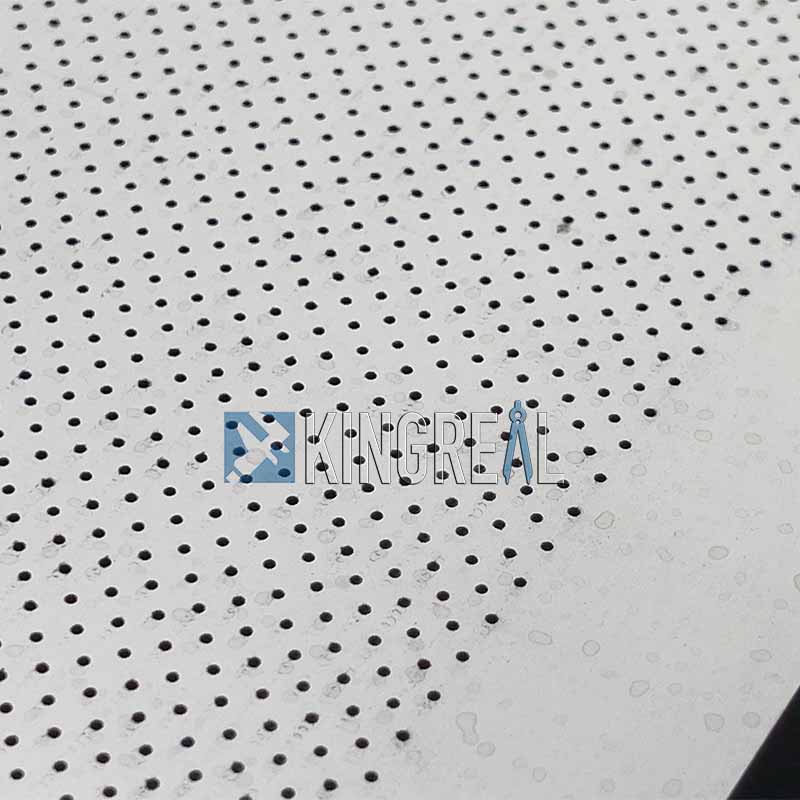

Perforated baffle ceilings: used for interior decoration, providing good ventilation and aesthetic effects.

The production of these products requires high-precision punching technology to ensure functionality and aesthetics. The introduction of sheet metal perforation machines has fundamentally changed the production methods of these industries.

Aspects of Steel Perforated Machines Changing Production Methods

(1) Improve production efficiency

The sheet metal perforation machine significantly improves production efficiency with its fully automated design. Traditional punching methods usually rely on manual operation, which is inefficient and prone to errors. Modern perforated metal machines are equipped with automated decoilers, leveling machines and punching machines, which can save manpower to the greatest extent.

Fully automated decoiler: This equipment can automatically unwind metal coils, reduce manual intervention, and reduce operational risks. Compared with manual unwinding, fully automated unwinding machines not only increase production speed, but also reduce material loss.

The role of the leveling machine: The leveling machine can effectively eliminate the corrugation and unevenness of the metal coil, ensure the flatness of the metal, and provide a high-quality foundation for subsequent punching. The automation of this process greatly improves work efficiency and ensures the continuity of production.

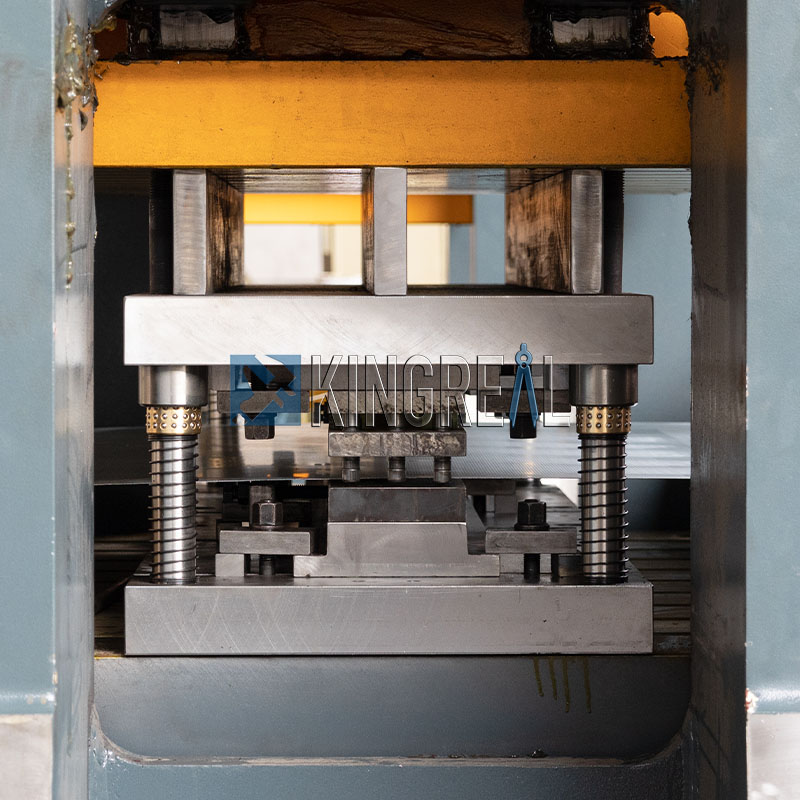

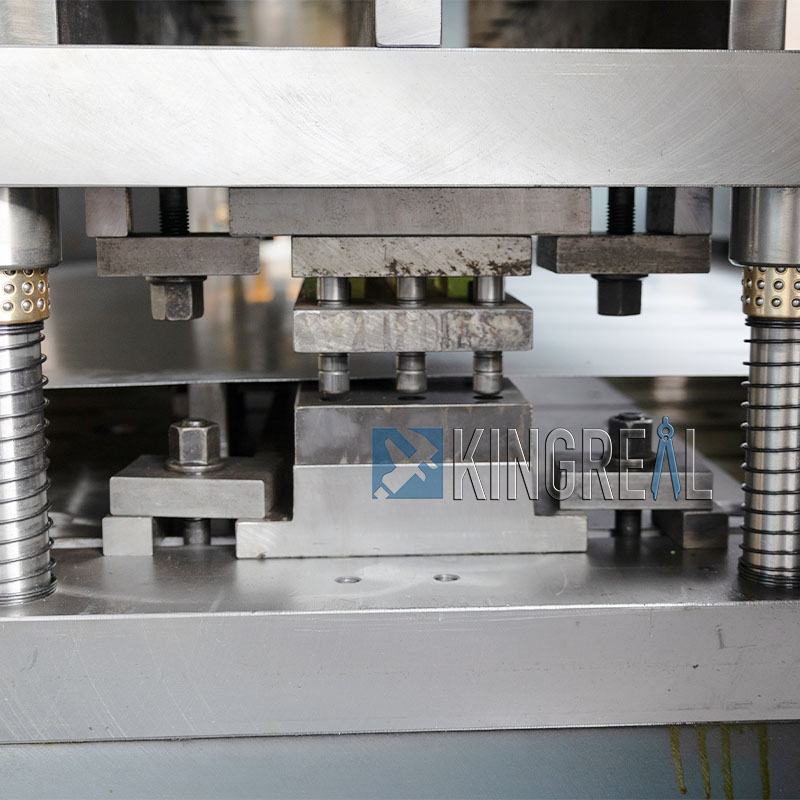

Efficient punching machine: The punching machine of the sheet metal perforation machine can complete high-precision punching in a short time, ensuring the stability and consistency of production. Through automated control, human errors in the production process are effectively controlled, and the qualified rate of products is improved.

(2) More flexible production

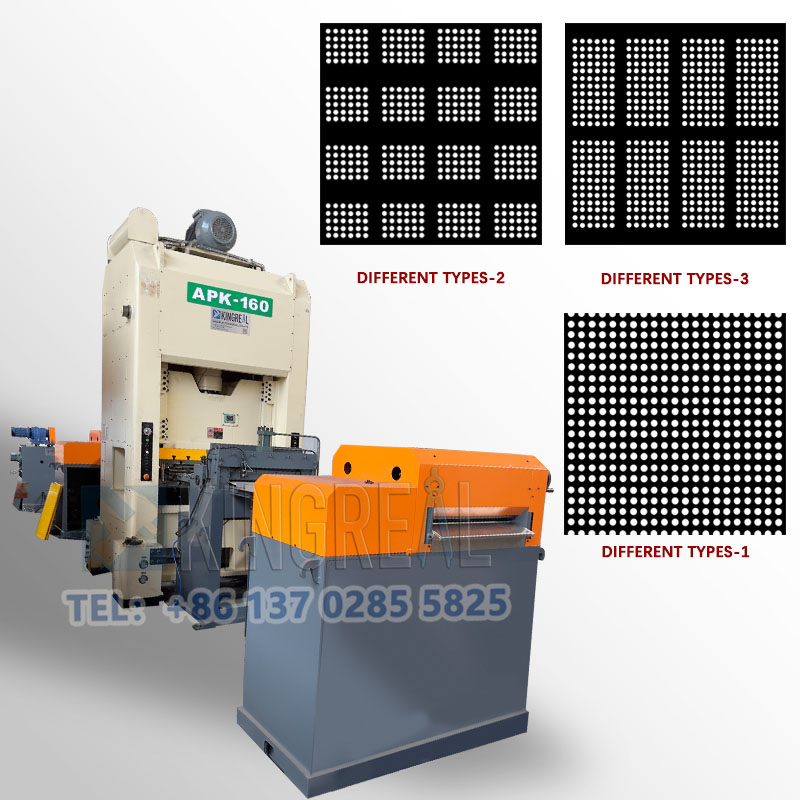

Another major advantage of the steel perforated machine is its production flexibility. By replacing the punching die, the company can manufacture products of different types or apertures on the same sheet metal perforation machine. This flexibility is particularly important in a rapidly changing market environment and can help companies quickly adapt to customer needs.

Customized punching dies: KINGREAL CEILING MACHINERY engineers can customize according to the customer's actual drawings to ensure that the punching die meets specific production requirements. Such personalized services not only improve customer satisfaction, but also ensure the efficiency of production.

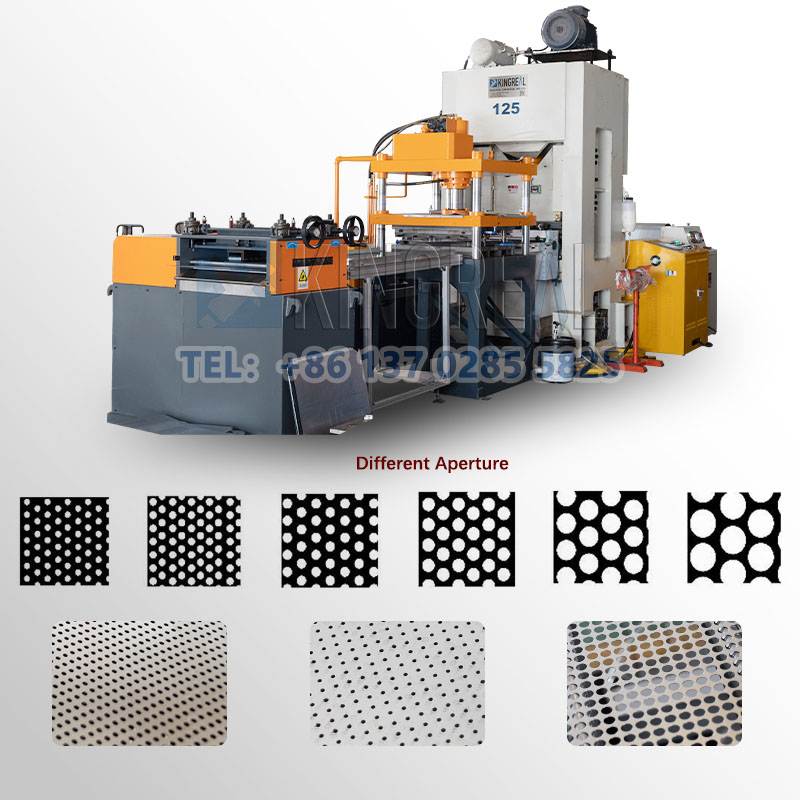

Achievement of multiple apertures and shapes: By replacing different punching dies, the perforated metal machine can quickly achieve punching of different apertures and shapes. This feature enables enterprises to easily switch production lines, quickly respond to market changes, and meet the needs of different customers.

Reduce production cycle: Flexible production mode enables enterprises to complete the production of different products in a short time, reducing the production cycle. This is especially important for industries that require fast delivery, such as the construction and home appliance industries.

(3) Design of targeted steel perforated machines

KINGREAL CEILING MACHINERY provides a variety of steel perforated machines, including coil to coil perforation lines, steel perforated machines with cutting, and metal ceiling perforation lines. Each perforated metal machine is carefully designed to target specific application scenarios and product requirements to ensure production efficiency and product quality.

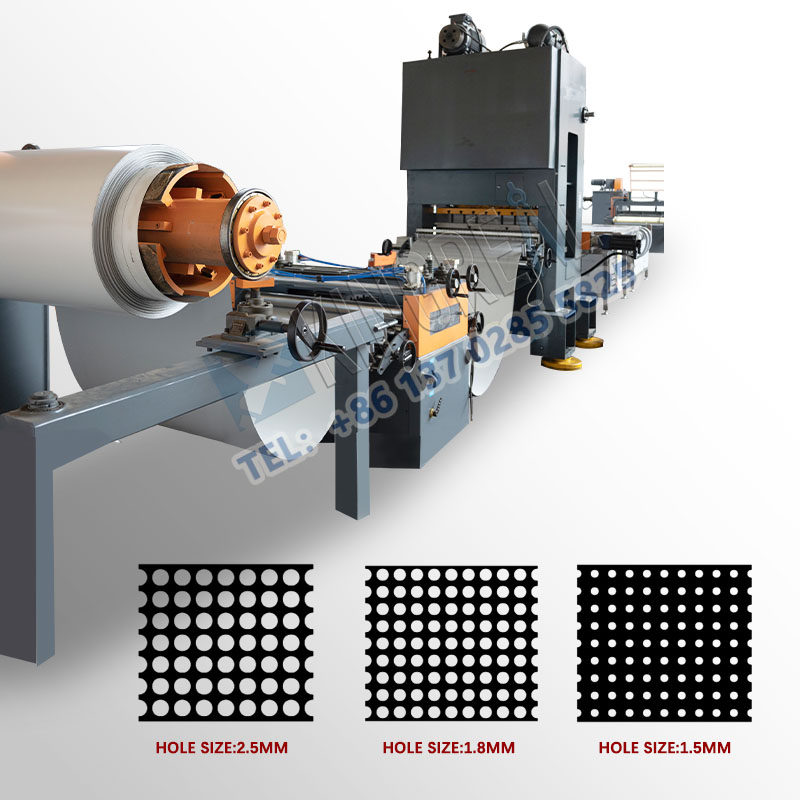

Coil to coil perforation line: Designed for customers who need to wind up perforated metal coils. This steel perforated machine is suitable for manufacturing perforated screens, filters, and other products that require coil form. Through advanced winding technology, customers can achieve efficient coil management while punching, reducing the complexity of subsequent processing.

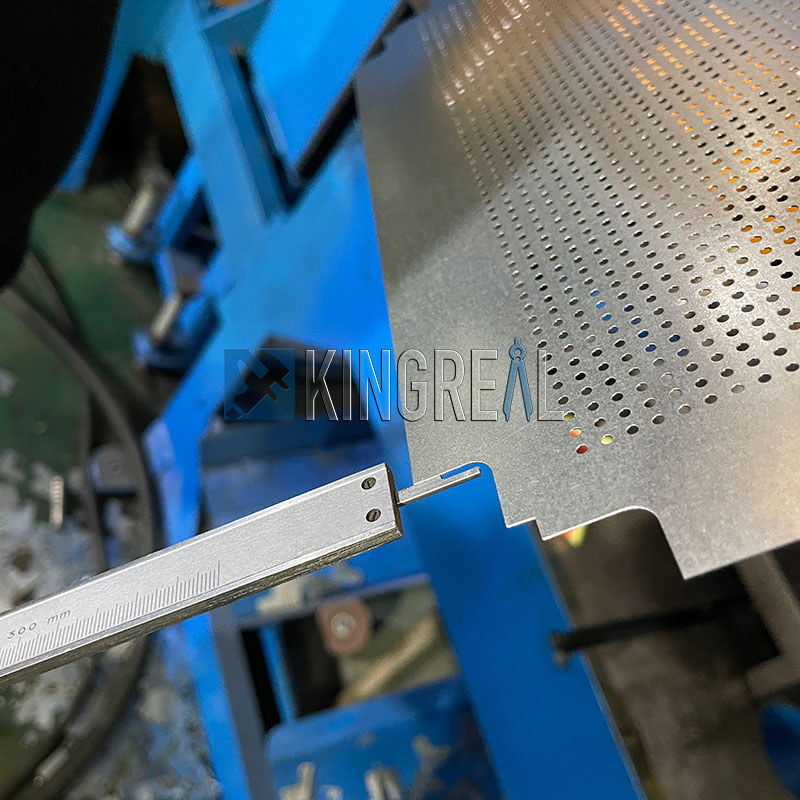

Steel perforated machine with cutting: This sheet metal perforation machine is suitable for customers who need to cut punched metal sheets to meet strict requirements on product size and shape. Through the automated shearing system, customers can quickly switch between different product specifications and improve production flexibility. This design is particularly suitable for small-batch production needs in the home appliance, automotive and construction industries.

Metal ceiling perforation line: In response to the special needs of the construction industry, KINGREAL has launched a metal ceiling perforation line. This sheet metal perforation machine can efficiently produce perforated metal ceilings to meet the aesthetic and functional requirements of architectural decoration. Through precise punching and flexible mold replacement, the production line ensures high quality and consistency of the product.

For some customers who have multiple production process requirements at the same time, KINGREAL CEILING MACHINERY also provides modular perforated metal machines with integrated recoiler and cutting stations. This innovative design allows customers to flexibly switch between different production modes on the same production line, greatly improving production flexibility and efficiency.

For example, when customers change their needs, they can quickly switch the steel perforated machine from punching and winding mode to punching and shearing mode without making complex equipment adjustments. This flexibility not only improves production efficiency, but also reduces equipment idle time and reduces production costs.

(4) Improve product quality

The introduction of sheet metal perforation machines not only improves production efficiency, but also significantly improves product quality. Precise punching technology ensures that every product meets strict quality standards.

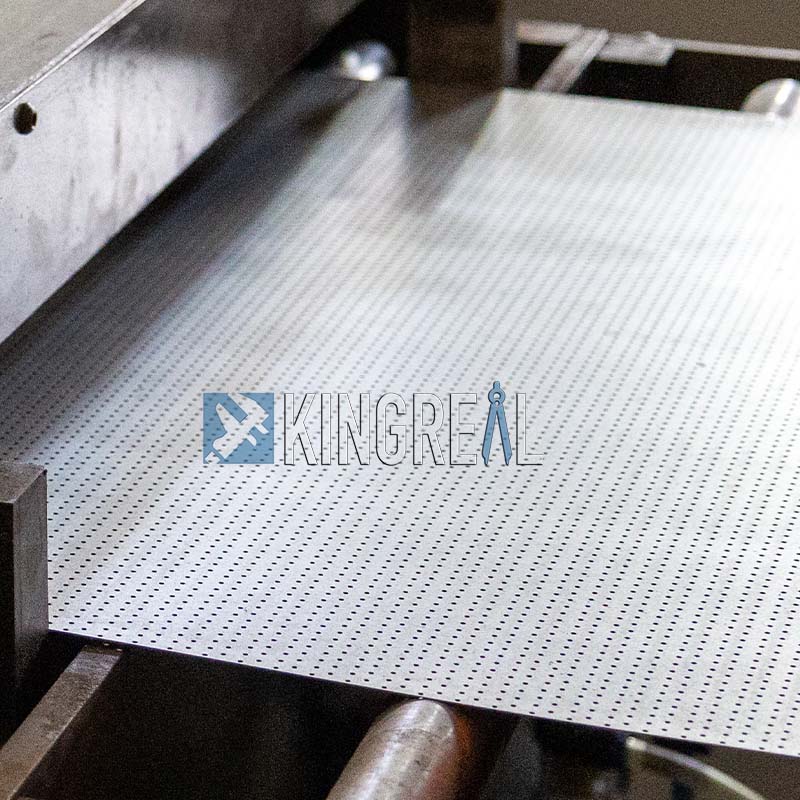

High-precision punching: Modern perforated metal machines use advanced cutting technology to achieve high-precision punching. This precision is particularly important for industries that require strict tolerances, ensuring the quality and performance of the finished product.

Consistency and stability: The fully automated sheet metal perforation machine ensures the consistency of the quality of each punching and reduces quality fluctuations caused by human factors. This stability gives companies more advantages in market competition.

Reduce scrap rate: Through precise punching and reasonable production processes, perforated metal machines minimize material waste and reduce production costs. Efficient material utilization not only improves the profitability of the company, but also helps to achieve sustainable development.

Get the latest price? We'll respond as soon as possible(within 12 hours)