How to improve working efficiency of metal ceiling machine?

2025-03-26 17:00

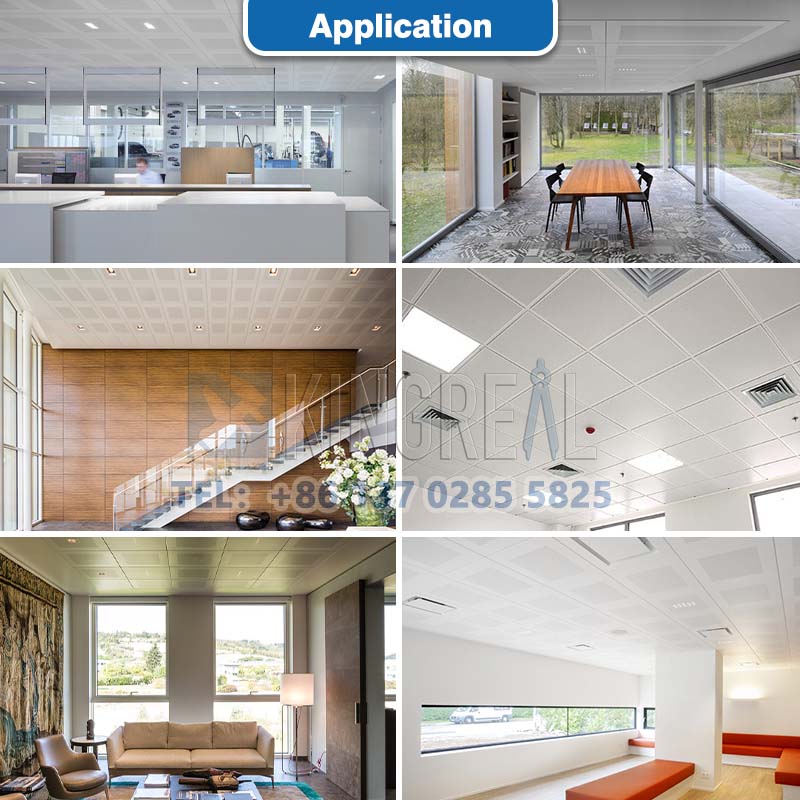

Metal ceiling machine is an indispensable key equipment in the modern construction industry. It produces metal ceilings of different types and sizes, such as clip in ceilings, lay in ceilings and tegular ceilings, etc. by leveling, punching and cutting metal raw materials. These metal ceilings are widely used in commercial buildings, home decoration and industrial facilities, and can meet the needs of different customers, such as 300x300mm, 300x600mm, 600x600mm and other specifications.

As people's requirements for building quality and beauty continue to increase, the market demand for ceilings is also growing. KINGREAL CEILING MACHINERY's metal ceiling production line has been successfully exported to Russia, Saudi Arabia, India, the United Arab Emirates, Turkey and other countries, fully demonstrating its competitiveness and influence in the global market. In this article, KINGREAL CEILING MACHINERY will explore with you how to improve the working efficiency of the aluminum ceiling tile machine.

Characteristics of metal ceilings

As an important part of building decoration, the market demand for ceilings mainly comes from the following aspects:

1. Aesthetics

Modern buildings pay more and more attention to exterior design. As an important element of interior decoration, ceilings directly affect the beauty of space. Whether in residential environments or commercial places, the design and materials of ceilings can significantly enhance the visual effect of the overall indoor environment. Consumers not only want to choose ceilings with beautiful appearance, but also expect these ceilings to be harmoniously matched with other indoor decorative elements to create a unified and comfortable space atmosphere. In addition, with the diversification and personalization of people's aesthetic concepts, the demand for customized ceilings in the market is also growing, which puts higher requirements on the flexibility and diversity of metal ceiling panel production lines.

2. Functionality

In addition to beauty, ceilings must also have a variety of practical functions. Modern ceiling design takes into account multiple needs such as sound insulation, heat insulation, and fire prevention. Especially in commercial buildings and public places, the functional requirements of ceilings are more prominent. For example, in places such as hospitals, schools, and conference centers, good sound insulation can effectively reduce noise interference and enhance user experience. In hot or cold environments, the thermal insulation performance of the ceiling can also effectively improve indoor comfort and reduce energy consumption. In addition, fire prevention is an important consideration for ceiling materials. Ceilings that meet fire protection standards can effectively reduce fire risks and ensure the safety of buildings.

3. Building standards and specifications

As the standards of the construction industry are improved, relevant regulations have put forward higher requirements on the materials and performance of ceilings. This is not only related to the safety and durability of the building, but also directly affects the compliance of the building. Therefore, the market demand for high-quality ceilings that meet national and regional standards is increasing. Manufacturers must strictly follow these standards during the production process to ensure the reliability and safety of the products. At the same time, with the increase in environmental awareness, many construction projects have begun to give priority to pollution-free and recyclable materials, which further promotes the demand for environmentally friendly ceilings.

Tips for improving the work efficiency of aluminum ceiling tile machine

On the premise of ensuring product quality, it is particularly important to improve the work efficiency of metal ceiling panel production lines. The following are some effective strategies and suggestions from KINGREAL CEILING MACHINERY. If you have other special ideas for the design of aluminum ceiling tile machines, please feel free to consult KINGREAL CEILING MACHINERY:

Fully automated aluminum ceiling tile machine

The fully automated metal ceiling panel production line provided by KINGREAL CEILING MACHINERY consists of multiple efficient components, including Hydraulic Decoiler、Precision Straightener、Perforation Press、Servo feeding machine、Notching and shearing press、2nd Precision straightener、Tiles flipping machine、Automatic tiles feeding machine、Auto bending forming press, etc. The biggest advantage of this automated aluminum ceiling tile machine is:

- Reduce manual operation: The fully automated system greatly reduces manual intervention and reduces the risk of human operation errors.

- Improve production efficiency: After setting the parameters, the metal ceiling panel production line can run continuously to ensure production efficiency and avoid fatigue and errors caused by manual operation.

- Improve product consistency: Automated aluminum ceiling tile machine can maintain stable production conditions, ensure the quality and specifications of each ceiling are consistent, and reduce the defective rate.

KINGREAL CEILING MACHINERY provides a feeding trolley for the decoiler of the aluminum ceiling tile machine, which can automatically transport the metal coil to the decoiler. The benefits of this design are:

- Reduce workers' handling work: The automatic feeding trolley can effectively reduce the workload of workers in material handling and improve work efficiency.

- Reduce material loss: Automatic feeding reduces material loss that may be caused by manual handling and ensures full utilization of raw materials.

During the production process of the ceiling, metal materials may be attached with dust and oil. The metal sheet cleaning machine provided by KINGREAL CEILING MACHINERY can automatically transport the ceiling to the metal sheet cleaning machine for cleaning and drying after production is completed. The advantages of this configuration include:

- Improve the integrity of the production process: One aluminum ceiling tile machine can complete all processes, simplifying the production process and saving time.

- Reduce subsequent cleaning work: The automatic cleaning function reduces the need for subsequent cleaning of the ceiling and improves production efficiency.

Acoustic fleece sticking machine

For ceilings that require sound absorption, KINGREAL CEILING MACHINERY can provide a acoustic fleece sticking machine to stick the sound-absorbing cloth to the ceiling. The advantages of this value-added service are:

- Meet the diverse needs of customers: Sound-absorbing ceilings can be produced according to the specific requirements of customers, enhancing the market competitiveness of products.

- Improve production flexibility: The application of acoustic fleece sticking machines enhances the flexibility of metal ceiling panel production lines, enabling them to quickly adapt to the production needs of different products.

Perforated metal ceiling tile machine

KINGREAL CEILING MACHINERY also provides metal ceiling perforation lines, which can be used in conjunction with aluminum ceiling tile machines to efficiently produce punched ceilings. The punching mold can be customized according to customer drawings to ensure the accuracy and consistency of punching. Its advantages include:

- Increase product added value: Perforated ceilings usually have better ventilation and aesthetics, which can meet the market demand for high value-added products.

- Ensure production accuracy: Customized punching molds ensure the accuracy of punching and reduce product quality problems caused by inaccurate hole positions.

Improving the efficiency of the metal ceiling panel production line can not only improve the production capacity of the enterprise, but also enhance the market competitiveness. Through fully automated metal ceiling panel production lines, reasonable production configuration and efficient equipment use, KINGREAL CEILING MACHINERY provides customers with a variety of effective aluminum ceiling tile machine manufacturing solutions to meet the growing market demand.

With the continuous development of the construction industry, the aesthetic and functional requirements of the ceiling will become more stringent. KINGREAL CEILING MACHINERY will continue to be committed to technological innovation and product upgrades, providing customers with more efficient and high-quality metal ceiling panel production line solutions, helping customers achieve greater success in the market.

Get the latest price? We'll respond as soon as possible(within 12 hours)