How to use open cell ceiling machine?

2025-04-25 17:00

The open cell ceiling machine is a kind of equipment specially used to produce open cell ceilings of various sizes and types. These ceilings not only have unique aesthetic effects, but also effectively enhance the use value of indoor space. Common types of open cell ceiling include pyramid grilyato ceilings, C-shaped grilyato ceilings and U-shaped grilyato ceilings. With the continuous development of the construction and interior design industries, the application of grilyato ceiling machines has become more and more extensive, and has become an indispensable equipment in modern architectural decoration. In this article, KINGREAL CEILING MACHINERY will introduce the application, use method, and daily maintenance tips of the open cell ceiling machine in detail to help users give full play to the performance of the equipment.

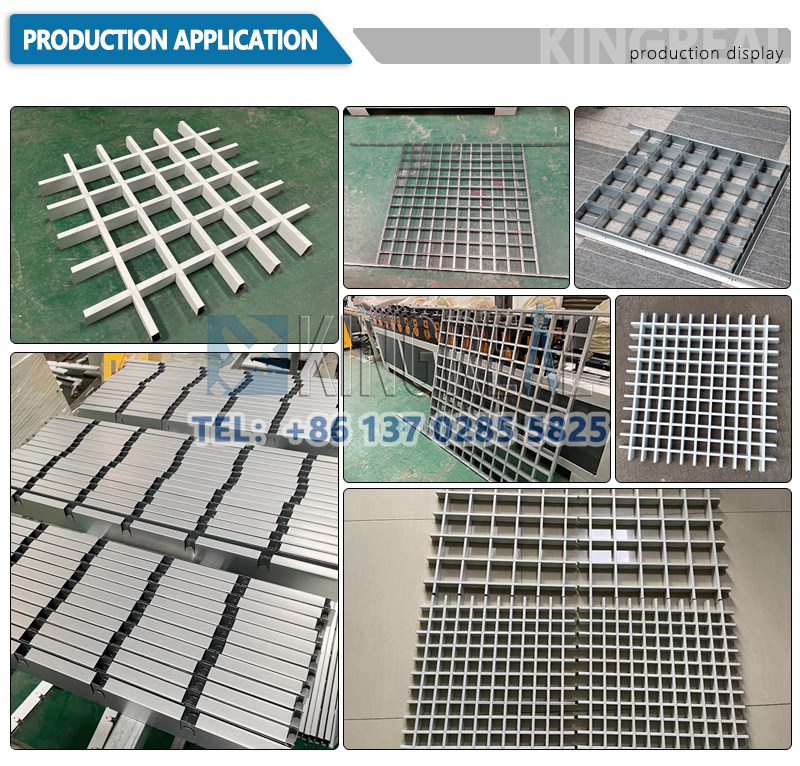

Application of Grilyato Ceiling Machine

1. The aesthetics of open cell ceilings

The open cell ceiling is widely popular for its unique design and beautiful appearance. This kind of ceiling is usually used in commercial buildings, office spaces, shopping malls, hotels and other places, which can effectively enhance the visual effect of the interior. Through different open cell ceiling styles and color matching, designers can create rich layering and decorative effects in the space.

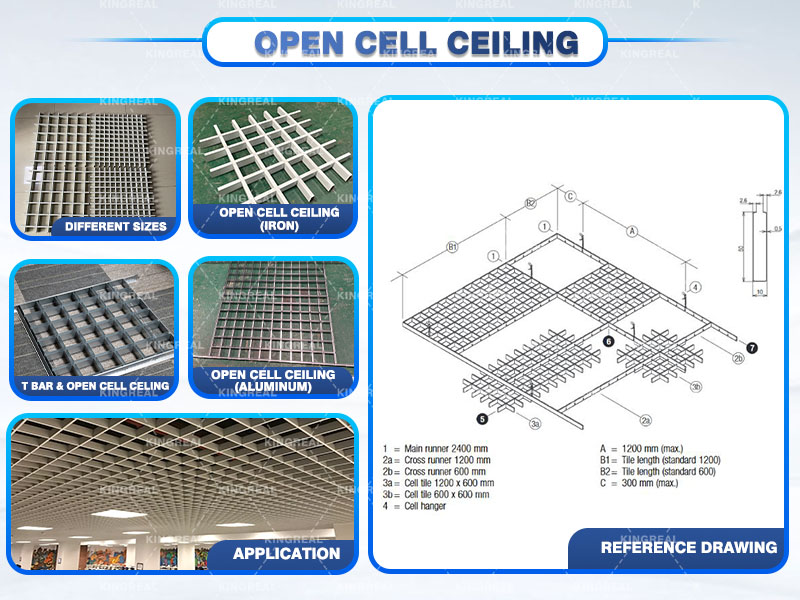

2. Collaborative use with ceiling t bar machine

The grilyato ceiling machine can be used with the ceiling t bar machine to form a complete open cell ceiling system. The ceiling t bar machine is responsible for producing the surrounding support structure, while the grilyato ceiling machine focuses on making the internal open cell ceiling part. Through this combination, the overall stability and aesthetics of the ceiling can be effectively improved, making it not only functional but also aesthetically pleasing.

3. Diverse application areas

The application areas of grilyato ceilings are very wide. In addition to common commercial buildings and office spaces, they are also commonly used in schools, hospitals, exhibition halls, conference centers and other places. These spaces have high requirements for acoustic effects and aesthetics, and grilyato ceilings can just meet these needs. Through reasonable design and layout, grilyato ceilings can not only improve the indoor acoustic environment, but also effectively reduce noise and create a more comfortable space.

Use of Open Cell Ceiling Machine

1. The importance of correct use

The correct use of the grilyato ceiling machine can not only improve production efficiency, but also extend the service life of the open cell ceiling machine. Users should be familiar with the operating procedures of the equipment, operate according to the instructions, and ensure that every step meets the requirements. Improper operation may cause equipment failure and even affect the safety of production and the quality of the product.

2. Operation steps

Before using the grilyato ceiling machine, users need to make adequate preparations, including equipment inspection, material preparation, and confirmation of the operation process. The following are the general steps for using an grilyato ceiling machine:

a. Uncoiling

First, the user needs to place the metal coil on the decoiler to ensure that the coil is placed stably. The function of the decoiler is to unwind the coil from the roll and prepare it for subsequent leveling and punching. During this process, the user needs to pay attention to controlling the tension of the coil to ensure that it does not wrinkle or deform when it is unrolled.

b. Leveling

The leveling machine is responsible for correcting the unrolled metal material to ensure that its surface is flat. The leveling process is crucial for subsequent punching, as uneven materials may lead to reduced punching accuracy. Users should regularly check the status of the leveling machine to ensure that it is working properly.

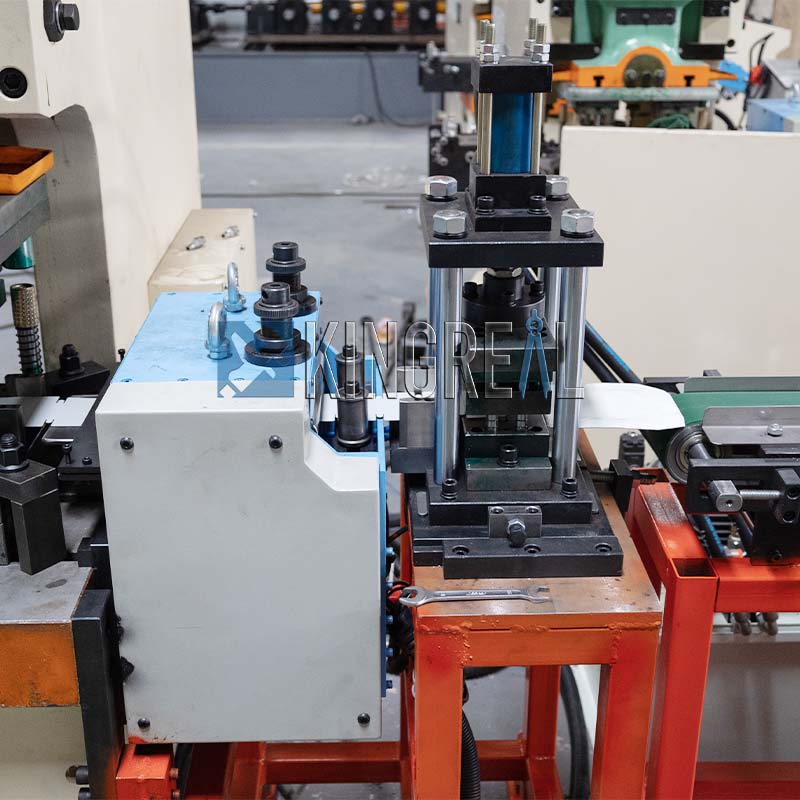

c. Punching

Punching is the core process of the grilyato ceiling machine. According to the design requirements, the grilyato ceiling machine will punch holes of preset shapes and sizes on the metal material. During this process, the operator needs to set the punching parameters according to the product design drawings to ensure that the size and position of each hole meet the requirements. The performance of the perforation press directly affects the quality of the final product, so users should regularly maintain and overhaul the perforation press.

d. Cutting

After punching, the material enters the shearing stage. According to customer needs, the cut-to-length press machine cuts the material into the required length. In this process, users need to ensure the accuracy of shearing to avoid material waste. The cut open cell ceilings should be sorted in time to facilitate subsequent molding.

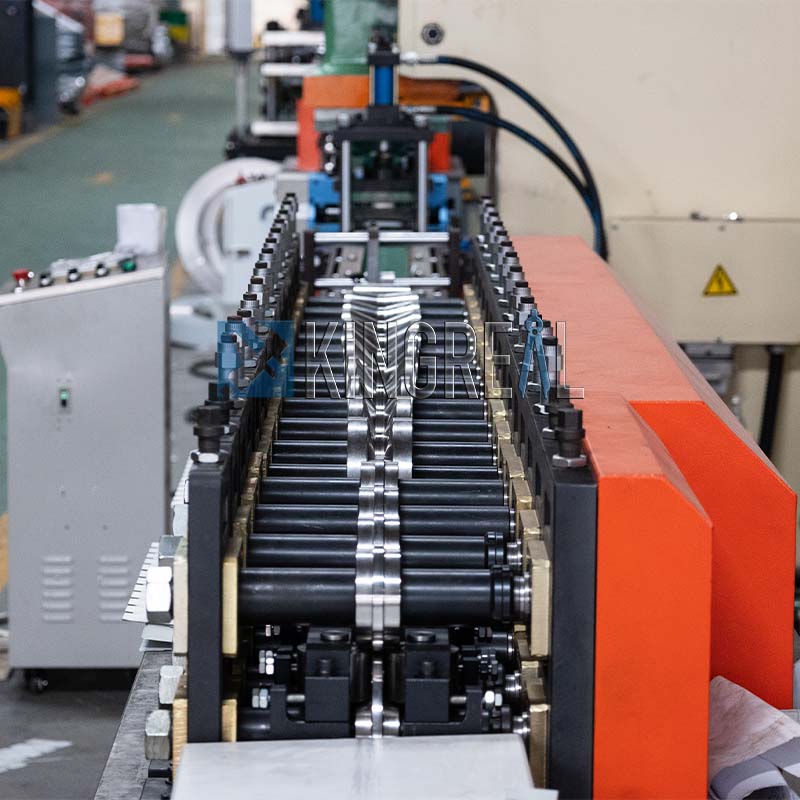

e. Forming

Finally, the material after punching and shearing will enter the forming stage. The roll forming machine will mold the open cell ceilings into the final shape according to the design requirements. Users need to ensure that the parameters of the roll forming machine are set correctly to ensure the quality and stability of the final product.

Tips for Use Open Cell Ceiling Machine

1. Daily maintenance

In order to ensure the long-term and stable operation of the open cell ceiling machine, regular daily maintenance is essential. Users should regularly check the various components of the open cell ceiling machine, including motors, cutters, transmission systems, etc., to ensure that they are in good working condition. Here are some tips for daily maintenance:

Clean grilyato ceiling machine: Regularly clean metal chips and dust from the open cell ceiling machine to prevent damage to the equipment.

Lubrication maintenance: Regularly lubricate moving parts to reduce wear and extend the life of the open cell ceiling machine.

Check the electrical system: Regularly check the electrical circuits and control systems to ensure that there is no looseness or damage.

Record operating data: Keep open cell ceiling machine operation records for subsequent analysis and maintenance.

2. Operator training

Ensure that operators are fully trained and master the operation methods and safety precautions of the grilyato ceiling machine. Regularly conduct operation training and skills improvement to adapt to the replacement of new technologies and new equipment.

3. Equipment upgrade

With the continuous advancement of technology, consider upgrading or replacing old open cell ceiling machine to improve production efficiency and product quality. The new generation of open cell ceiling machines usually have a higher level of automation and stronger functions, which can provide customers with a better production experience.

Get the latest price? We'll respond as soon as possible(within 12 hours)