How does a metal punching machine work?

2024-12-27 12:15

Definition of Perforated Metal Machine

Perforated metal machine is an automated production equipment specially used for punching metal sheets. By placing the metal sheet on the punching machine, the punch and die are used to punch holes of different sizes, shapes and types on the metal sheet.

These holes can be of various geometric shapes, such as round holes, square holes, rectangular holes, diamond holes, hexagonal holes, cross holes, etc., which can meet the processing needs of metal sheets in different fields. The design of the punching line usually includes multiple modules, which are automated, precise and efficient, and can greatly improve the processing efficiency and reduce the intervention of manual operation during the production process. |  |

Workflow of Metal Perforation Machine

The working principle of the perforated metal machine is to accurately control the punching action of the metal perforation machine through an automated control system. The metal sheet is fed into the metal perforation machine through a conveying system, and at the set speed and pressure, the punch accurately punches the metal sheet through the die.

According to customer needs, the metal punching machine can realize the simultaneous punching of single holes and multiple holes, and even the punching of complex patterns and shapes.

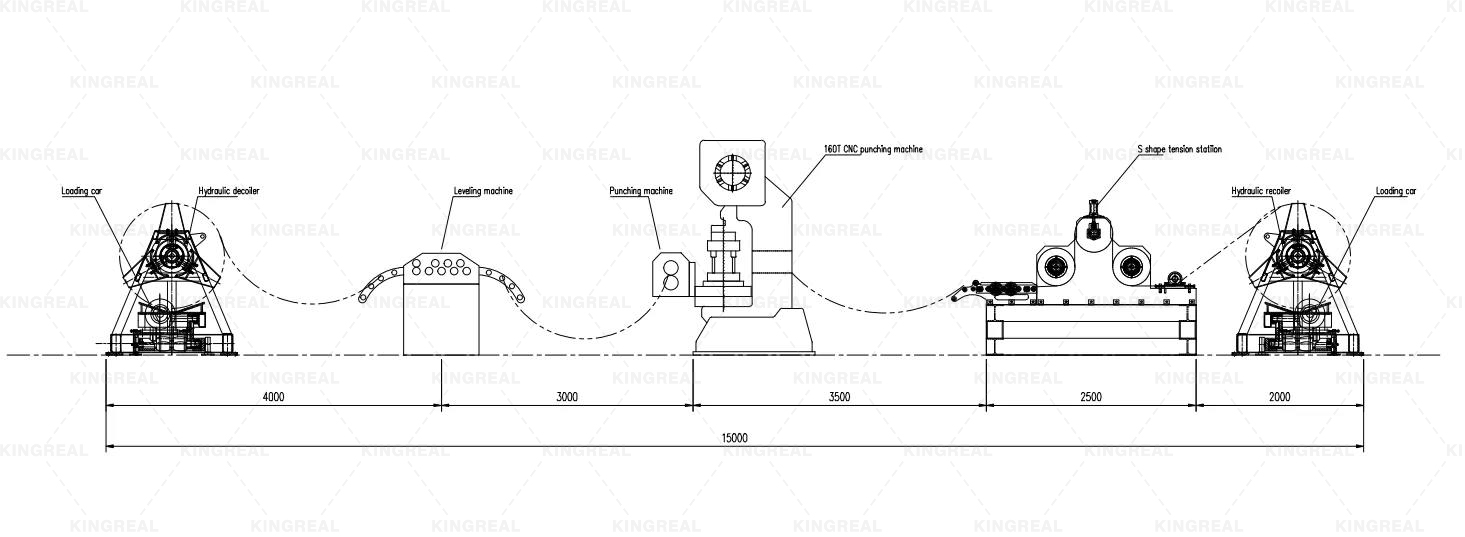

Metal perforation machine usually consists of an decoiler, a leveler, a metal punching machine, a transmission device, a winding device, etc. The decoiler unwinds the metal coil and feeds it into the leveler for leveling. The leveled metal sheet is fed into the metal punching machine through the transmission device.

During the punching process, the metal sheet is pressed into the corresponding mold, and the hole shape at the set position is accurately punched out by the impact force of the punch. After the punching is completed, the punched sheet will continue to be sent to the subsequent process through the transmission device, or directly stacked, packaged, etc.

Application of Perforated Metal Machine

The metal perforated sheet produced by the metal perforation machine is widely used in many industries and fields, including but not limited to:

-Construction industry: Perforated sheets are often used for decorative materials such as building facades, interior walls, and ceilings. Especially in steel structure buildings, perforated sheets not only have decorative effects, but also have functions such as ventilation and light transmission.

-Automobile manufacturing: In the automobile industry, perforated sheets are often used for body shells, windows, air intakes and other parts.

-Home appliance industry: Perforated sheets are used for the shells, heat sinks and other parts of home appliances, such as refrigerators, air conditioners, electric heaters, etc. |  |

-Electronic products: Electronic equipment housings and heat dissipation components require a large number of perforated sheets, especially in situations where high-precision hole shapes and densities are required. -Ventilation equipment: Used to manufacture air conditioners, ventilators, ventilators and other products, these devices often require perforated sheets to ensure air circulation. -Screens and filters: Perforated sheets are widely used to manufacture different types of screens and filters, and are used in mining, petrochemicals, food processing and other industries. -Decoration industry: In some modern buildings and interior designs, perforated sheets are not only used as practical functional materials, but also as decorative elements to increase aesthetics and artistic sense. |  |

Video About Perforated Metal Machine

KINGREAL CEILING MACHINERY Three Perforated Metal Machine Solutions

1. Metal sheet perforated machine

The metal sheet perforated machine consists of main components such as decoiler, precision leveling machine, metal punching machine, and cutting station. In order to maximize the production speed of customers and reduce labor costs, KINGREAL CEILING MACHINERY has specially equipped the metal sheet perforated machine with an automatic feeding trolley. Through this trolley, the metal coil can be automatically fed into the decoiler, eliminating the trouble of workers manually carrying heavy metal coils. This not only improves production efficiency, but also reduces the risk of human operation and ensures the safety of the production process. |  |

2. Coil to coil perforation line

KINGREAL CEILING MACHINERY coil to coil perforation line consists of key components such as decoiler, precision leveling machine, punching machine, and recoiler. It is particularly suitable for production needs that require the whole roll of metal plates after punching. In the configuration of the coil to coil perforation line, KINGREAL CEILING MACHINERY has added a metal sheet cleaning machine for customers. After punching, the equipment cleans the metal plate to remove dirt, oil and residue on the surface of the plate, ensuring that the metal plate is clean and tidy after winding. This design greatly reduces the cleaning and processing time caused by dirt in subsequent processes and improves the overall efficiency of production. |  |

3. Metal ceiling tile perforation line

KINGREAL CEILING MACHINERY Metal Ceiling Tile Perforation line is a device designed specifically for metal ceiling production. It can be used with KINGREAL CEILING MACHINERY's metal ceiling production line to produce metal ceilings with holes. According to the customer's production needs, KINGREAL CEILING MACHINERY will select the appropriate punching tonnage (such as 125 tons or 160 tons) according to the customer's drawings and actual production conditions. If the customer has special production requirements, KINGREAL CEILING MACHINERY's engineers will tailor a higher tonnage punching line for the customer through detailed communication with the customer to meet their unique production needs. |  |

Get the latest price? We'll respond as soon as possible(within 12 hours)