What are the application of metal straightener machine?

2024-12-24 15:34

Definition of Metal Straightener Machine

Sheet metal straightener is a high-precision equipment that uses pressure to level the surface of materials. It is widely used in the surface treatment of various materials, such as metal sheets, plastic films, etc. By adjusting the size and distribution of pressure, the metal straightener machine can effectively eliminate the unevenness of the material surface, so that it can meet the specified flatness and precision requirements, thereby improving the processing quality and performance of the material.

The working principle of the sheet metal straightener is to put the material to be processed into the working area of the machine, and generate strong pressure through the drive device to level the material. In this process, the special structure and precise control system of the metal straightener machine ensure the uniform distribution and precise control of pressure, so as to achieve the ideal leveling effect.

Main Components of Sheet Metal Straightener

● Body: the main structure of the sheet metal straightener, which bears the pressure during the processing;

● Drive device: provides power for the metal straightener machine;

● Pressure system: adjusts the size and distribution of pressure;

● Control system: responsible for the operation and control of the machine to ensure that the leveling process is stable and reliable;

● Mold: directly affects the leveling effect and processing quality.

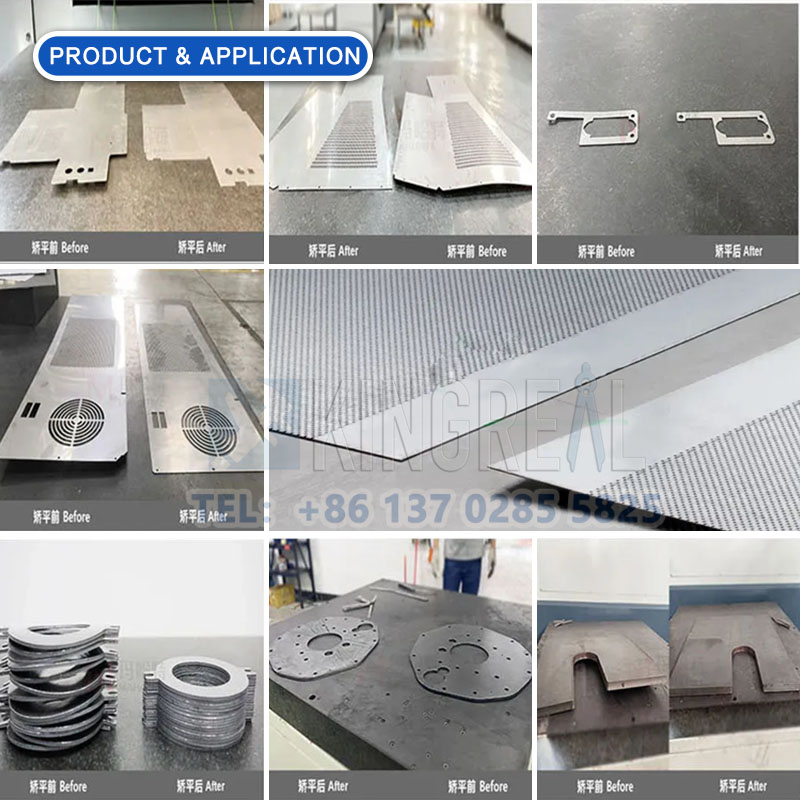

Application Fields of Metal Straightener Machine

The finished products after leveling are widely used in:

1. Manufacturing: metal sheet processing for vehicles, home appliances, building materials and other fields.

2. Metal processing: leveling metal sheets before stamping, cutting and welding.

3. Heavy industry: processing large and heavy plates, such as shipbuilding, large machinery manufacturing, etc.

It can not only improve the flatness and precision of the product, but also significantly improve production efficiency and product quality. With its high precision and flexibility, KINGREAL CEILING MACHINERY metal straightener machines can meet the diverse processing needs of customers and are suitable for a variety of materials and complex process scenarios.

Core Applications of

Sheet Metal Straightener

1. Plate leveling

KINGREAL CEILING MACHINERY metal straightener machines can accurately level various plates, including perforated mesh plates, special-shaped iron plates, cold water plates, aviation aluminum, etc.

Perforated mesh plates

- By releasing the internal stress of the material, KINGREAL CEILING MACHINERY high-precision metal straightener machines can improve the flatness of perforated mesh plates to a level that fully fits the marble platform.

Cold water plate

- It can level stainless steel cold water plate with a thickness of up to 23 mm, and the flatness can reach 0.80mm, which is widely used in the semiconductor industry.

Special-shaped iron plate

- It can level special-shaped iron plate with a thickness of 6 mm, and the flatness can reach 0.10mm, meeting high-precision requirements.

Aviation aluminum

- The flatness of aviation aluminum after leveling can be controlled within 0.10mm, which fits the marble platform perfectly and is suitable for the high standard requirements in the aviation manufacturing field.

2. Stick leveling

KINGREAL CEILING MACHINERY metal straightener machine also performs well in the field of stick leveling, especially for the straightening of hexagonal bars.

Hexagonal bar leveling

- It can level and straighten copper alloy hexagonal bars with a thickness of up to 30 mm. The processed bars become straight from the bent state, and the leveling effect is excellent.

The leveled hexagonal bars are widely used in construction, machinery, automobiles, ships, power and other industries. It can be used as a component or a connector between components in structures such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, and warehouse shelves. In addition, hexagonal bars can also be used as product raw materials to manufacture standard fasteners such as nuts and bolts.

Advantages of KINGREAL CEILING MACHINERY Metal Straightener Machine

1. Width flexibility: According to customer needs, KINGREAL CEILING MACHINERY metal straightener machine can handle raw materials with a width ranging from 200mm to 3800mm, adapting to production needs of various specifications.

2. Customizable roller diameter: The roller diameter ranges from 20mm to 260mm, which can be flexibly configured according to different materials and processing requirements.

3. Plate thickness range: KINGREAL CEILING MACHINERY sheet metal straightener can handle plate thicknesses from 1.5mm to 4mm, covering most industrial processing needs.

4. Efficient and accurate: The sheet metal straightener is equipped with advanced pressure control and automation systems to ensure stable and reliable leveling effects and significantly improve production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)