How many metal punching solutions are there?

2024-12-19 11:47

Metal perforated machine is a processing equipment that uses metal sheet as raw material, and punches various sizes and shapes of holes on the metal surface through processes such as unwinding, straightening, punching, and cutting. This process has the characteristics of high precision, strong flexibility, and wide adaptability. It is one of the indispensable important equipment in modern industrial manufacturing.

The application range of sheet metal perforated machine is extremely wide, and the punched metal products produced can be used in the following fields:

1. Building decoration:

- Perforated ceiling: used to enhance the interior decoration effect, while having good ventilation and sound absorption functions;

- Curtain wall decorative panels: as a decorative material for the exterior facade of the building, it has both beauty and durability;

- Guardrail decorative panels: used for indoor and outdoor guardrails, taking into account safety and decoration.

2. Industrial manufacturing:

- Punching filter element: widely used in filtering equipment and hydraulic systems;

- Mechanical protective cover: provides safety protection for industrial equipment to avoid operator injury;

- Industrial screen: used for screening and grading of particulate matter.

3. Daily consumer goods:

- Bread trays: Tray products used in the food baking industry, high temperature resistant and easy to clean;

- Metal furniture: Such as punching chairs, tabletops, etc., which are both functional and aesthetic;

- Home appliance ventilation panels: Used in air conditioners, fans and other equipment to improve ventilation efficiency.

4. Transportation facilities:

- Noise barriers: Used along highways and railways to reduce noise pollution;

- Anti-skid plates: Used in bridges, lanes, etc. to enhance safety;

- Subway station decorative panels: Both decorative and functional, improving the aesthetics of public facilities.

5. Agriculture and horticulture:

- Screens: Used for grain screening and processing;

- Ventilation panels: Used in ventilation systems for agricultural greenhouses;

- Animal feed screening equipment: Helps separate and process feed ingredients.

three customized metal sheet perforation line solutions

In order to meet the diverse needs of customers in different fields, KINGREAL CEILING MACHINERY provides three efficient customized sheet metal perforated machine solutions. These solutions not only optimize the production process, but also significantly increase the added value of the product.

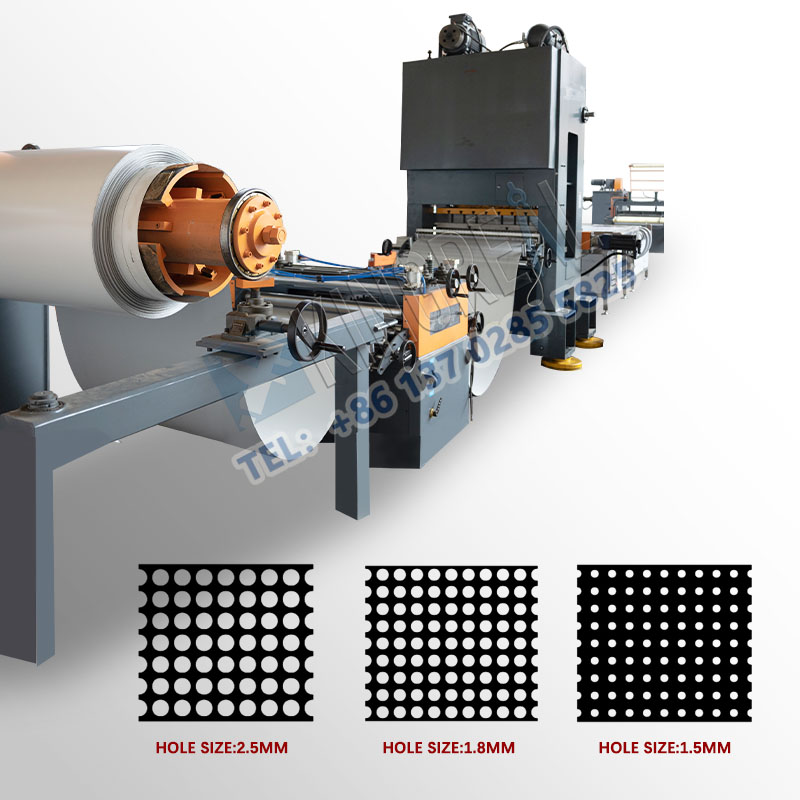

1. Coil perforated rewinding production line

KINGREAL CEILING MACHINERY coil perforated rewinding production line punches the metal sheet and then rolls it into a metal coil through a coiler. This production method is suitable for scenarios that require further processing and manufacturing, and is easy to transport and store.

⭐Application areas:

- Punching filter element: core components used in filtration systems;

- Bread tray: Provide high-quality baking trays for the food industry.

⭐ Features:

- Continuous production, high efficiency;

- The product is easy to process later and has strong flexibility.

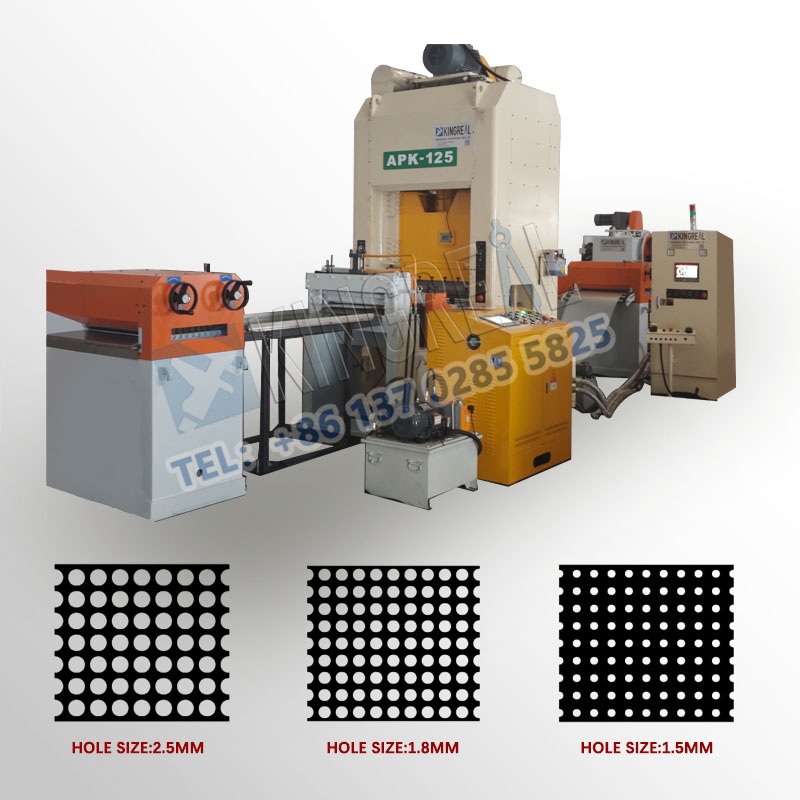

2. Metal sheet coil perforated cutting production line

After the punching process, KINGREAL CEILING MACHINERY metal sheet coil perforated cutting production line cuts the metal sheet into the required length through the shearing station, which is directly used by customers or further processed.

⭐Application areas:

- Decorative panels: such as building curtain walls and decorative wall panels;

- Mechanical protective covers: Provide precise protection for industrial equipment.

⭐ Features:

- Flexible and adjustable product size;

- Suitable for small batch and multi-specification production needs.

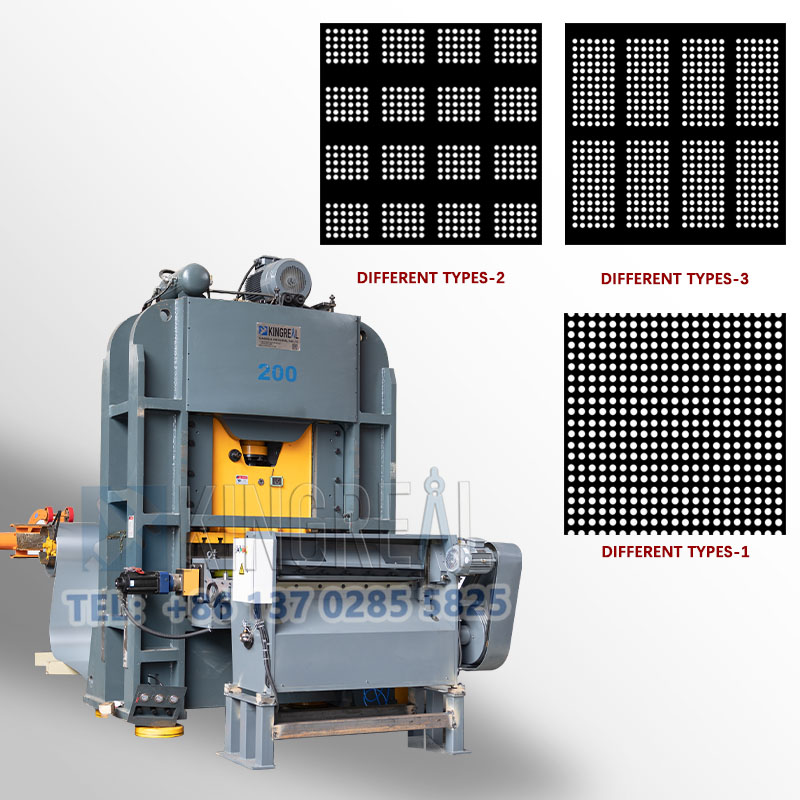

3. Metal ceiling tile perforated line

KINGREAL CEILING MACHINERY metal ceiling tile perforated line is specially designed for metal ceilings and can be seamlessly connected with the ceiling production line to produce high-quality perforated ceiling products.

⭐Application areas:

- Ceiling: suitable for commercial buildings, airports, subway stations and other places;

⭐ Features:

- Provide 125-ton and 160-ton high-speed punching lines;

- Support the production of ceilings of various specifications and patterns;

- High speed and stability, suitable for mass production.

KINGREAL CEILING MACHINERY's professional services and technical support

KINGREAL CEILING MACHINERY is customer-centric and provides a full range of services from equipment design to after-sales support:

1. Customized design: Tailor-made equipment according to customer needs to ensure that the production line fully meets the actual application needs;

2. Efficient after-sales service: From equipment installation to operation training, KINGREAL CEILING MACHINERY engineers follow up throughout the process to ensure that customers can quickly put into production;

3. Quality assurance: The equipment has been strictly tested to ensure that the precision error is controlled within 0.1mm, providing reliable performance support.

Through continuous innovation and optimization, KINGREAL CEILING MACHINERY is committed to creating greater value for customers. Whether it is architectural decoration, industrial manufacturing or daily consumer goods production, KINGREAL CEILING MACHINERY's sheet metal perforated machine can help customers achieve more efficient and higher-quality production goals.

Get the latest price? We'll respond as soon as possible(within 12 hours)