How to manufacture open cell ceilings?

2025-01-25 19:04

1. Open cell ceiling

Open cell ceiling is one of the ceiling materials produced in recent years. Grilyato ceiling has an open view, ventilation, air permeability, its lines are bright and regular, and its layers are distinct, showing a simple and clear modern personality.

It is simple and convenient to install and disassemble, and has become the main product in the popular decoration market in recent years. Among them, the open ceiling grid is made by a open cell ceiling machine through unwinding, leveling, punching, cutting, forming and other work processes.

2. Grilyato ceiling production line

2.1 Definition of open cell ceiling machine

KINGREAL CEILING MACHINERY grilyato ceiling production line can be compatible with two metal raw materials, and can make iron and aluminum grids on one production line. And the production speed is fast, up to 30m/min. The fully automatic open cell ceiling machine can produce grids of different sizes. In order to speed up production efficiency, KINGREAL CEILING MACHINERY designed a high-end grilyato ceiling production line equipped with a 63-ton punching machine, which can punch all holes at one time, saying goodbye to the previous situation of only punching one hole at a time.

2.2 Components of the open cell ceiling machine

The grilyato ceiling production line is mainly composed of precision equipment such as decoiler, precision straightener, punching machine, shearing station, and main roll forming machine.

3. The process of open cell ceiling manufacturing

Decoiler

The production of open cell ceiling starts with the unwinding of metal coils. The decoiler is the first process in the entire production process. Its main function is to pull the metal strip of the coil out of the reel and unwind it. Generally speaking, the decoiler controls the tension of the metal coil through a hydraulic system or mechanical device to ensure that the coil does not shrink or wrinkle during subsequent processing.

The decoiler uses a hydraulic expansion device to unwind the coil and adjusts the tension of the metal strip through an automatic control system to avoid deformation during processing. The metal coil is steadily pushed to the entrance part of the leveling machine to prepare for the next leveling process.

Precision Straightener

After the metal coil enters the Precision Straightener, it will undergo the leveling process of the leveling machine. The function of the Precision Straightener is to adjust the warped and uneven parts in the coil back to a flat state to ensure the accuracy and quality of subsequent processing.

The Precision Straightener is generally composed of multiple upper and lower rollers. The metal coil is compressed between the rollers to achieve the purpose of leveling its surface. The leveling machine can also adjust different roller pressures to adapt to metal coils of different thicknesses and materials. The leveled metal sheet is more flat, providing an ideal foundation for subsequent punching and forming.

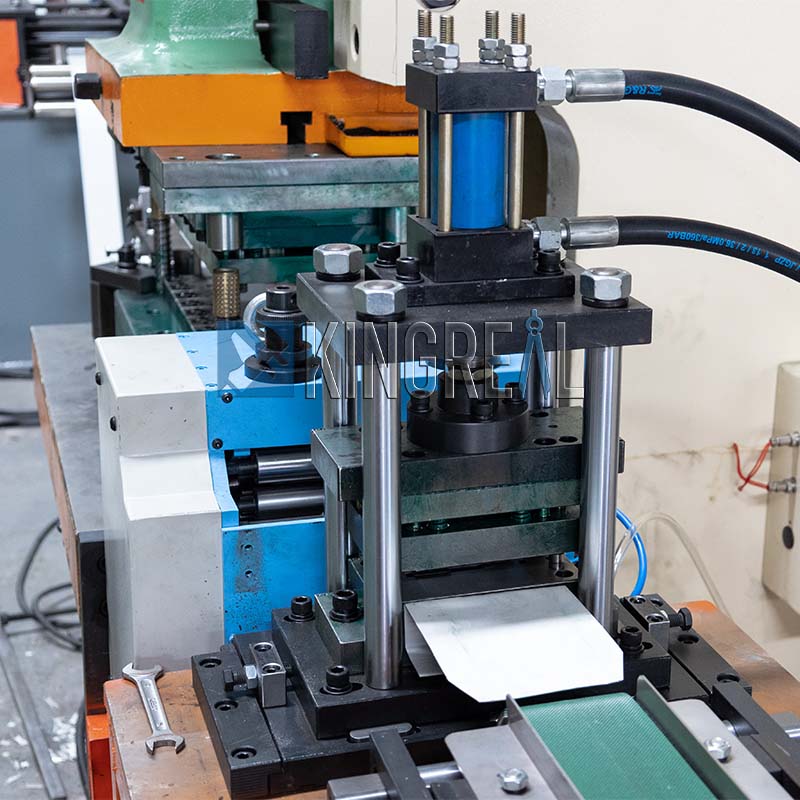

punching Machine

An important feature of the grid ceiling is that it has many regular holes. In the manufacturing process, the punching machine undertakes this key step.

The punching machine punches holes of a predetermined shape on the metal sheet through a die. The shape and size of the holes can be customized according to customer requirements. The punching machine can use pneumatic or hydraulic systems for high-precision punching to ensure that the hole size is accurate and evenly arranged. After punching, the metal sheet is evenly covered with holes, and the arrangement and spacing of the holes meet the design requirements, which lays the foundation for the final effect of the open cell ceiling.

Shearing station

After punching, the grilyato ceiling sheet needs to be sheared into the required size. Shearing stations are usually used to accurately cut metal sheets to ensure that the size of the produced ceiling meets customer needs.

Shearing stations usually use hydraulic shears or mechanical shears. The use of hydraulic systems can provide high shearing force, so that the metal sheets can be cut smoothly. The shearing process requires special attention to precision to ensure that the edges of each ceiling are neat and not warped or deformed.

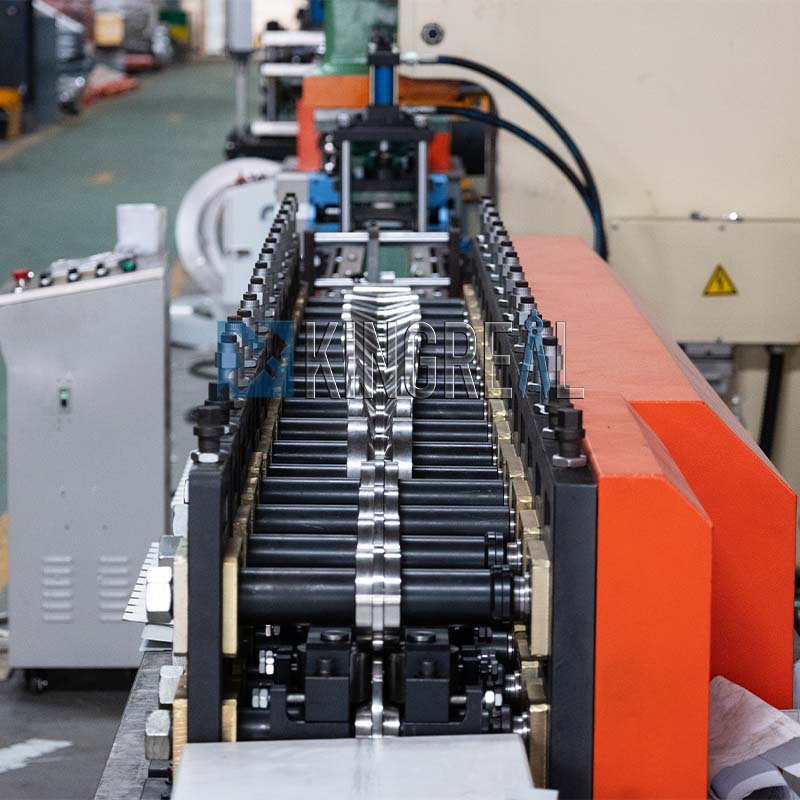

Main roll forming machine

The main roll forming machine is the core equipment in the production of grilyato ceilings. Its function is to press and form the punched metal sheets to form the final grid structure. The grilyato ceiling is usually composed of multiple slender metal strips or grids. The main roll forming machine deforms the metal sheet through a series of dies and pressing devices to complete the transformation from flat to grid.

The roll forming machine is usually equipped with multiple pressing dies and dies. Through step-by-step pressing and forming, the flat metal sheet is pressed into the desired shape. The forming process can include various methods such as roll forming, stamping forming and bending forming. The specific forming method depends on the design and process requirements of the grid ceiling. By adjusting the die and pressure, the roll forming machine can accurately control the size, shape and spacing of the open cell ceiling to ensure the consistency and accuracy of the product.

Get the latest price? We'll respond as soon as possible(within 12 hours)