Semi-Automatic vs Fully Automated suspended ceiling machine

2025-01-23 15:05

With the rapid development of modern construction industry, the demand for metal ceilings is also growing. Whether it is renovating old houses or building new houses, metal ceilings have become the first choice of many consumers and builders with their durability, environmental protection, and beauty. As an important part of this demand, suspended ceiling machines have also increased in demand in the market.

Against this background, KINGREAL CEILING MACHINERY has launched two different metal ceiling tile machine solutions: fully automatic suspended ceiling machine and semi-automatic suspended ceiling machine.

According to the different needs and production scale of customers, choosing a suitable production line will directly affect production efficiency and cost. Next, KINGREAL CEILING MACHINERY will introduce the difference between the two metal ceiling tile machines and the advantages of KINGREAL CEILING MACHINERY suspended ceiling machine in detail.

Differences between fully automatic and semi-automatic metal ceiling tile machines

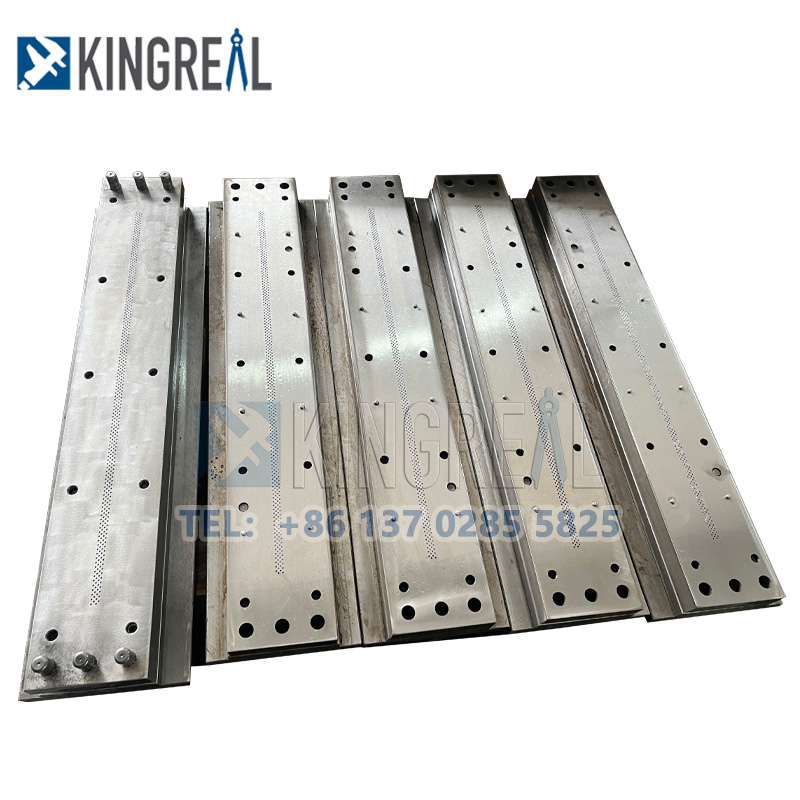

1. Differences in equipment composition

The biggest difference between fully automatic and semi-automatic metal ceiling tile machines lies in the equipment composition. The fully automatic suspended ceiling machine is equipped with more automated equipment, so that the entire production process requires almost no human intervention, while the semi-automatic suspended ceiling machine requires more human participation. Although the degree of automation is low, it can still provide efficient production capacity.

Fully automatic suspended ceiling machine includes:

- Decoiler

- Precision Straightener

- Perforation Press

- Servo feeder

- Notching and shearing press

- 2nd Precision straightener

- Tiles flipping machine

- Automatic tiles feeding machine

- Auto bending forming press

These devices work together and can greatly improve production efficiency, reduce manual operation and errors, and improve production stability through highly automated operations. In particular, the use of servo feeders and feeding robots can automatically feed and transport without human intervention, greatly improving the automation of the production line.

Semi-automatic suspended ceiling machine is relatively simple, lacking servo feeders, turners and feeding robots. This means that some links in the production process require human participation, such as manual feeding, manual adjustment and handling. Despite this, semi-automatic metal ceiling tile machines can still provide relatively efficient production capacity, suitable for factories with lower demand or smaller scale.

2. Applicable scale and production requirements

Since the fully automatic metal ceiling tile machine is equipped with more automated equipment, it is suitable for customers with larger production scale and higher production requirements. Fully automatic suspended ceiling machines can not only greatly improve production efficiency, but also maintain high precision and stability for a long time, especially in mass production, which can save a lot of labor costs and reduce errors caused by human factors.

In contrast, semi-automatic suspended ceiling machines are more suitable for factories with simpler production requirements and smaller scale. Because its equipment composition is relatively simple, the initial investment cost of purchase is low, which is suitable for those companies that are just starting out or factories with small business volume. As the business grows and the production scale expands, semi-automatic suspended ceiling machines can also be upgraded to fully automatic suspended ceiling machines to help companies gradually improve production capacity and meet higher market demand.

3. Production efficiency and speed

The production efficiency and speed of fully automatic metal ceiling tile machinesare much higher than those of semi-automatic metal ceiling tile machines.

Since fully automatic suspended ceiling machines are automated in all links, there is almost no need for human intervention in the production process, and 24-hour uninterrupted production can be achieved, with more efficiency and speed advantages. The rapid response and precise control of the machine enable the fully automatic suspended ceiling machine to maintain high precision while greatly increasing the production rate.

Although the semi-automatic suspended ceiling machine has improved production efficiency to a certain extent, the production speed is relatively slow due to the need for human intervention. Therefore, semi-automatic metal ceiling tile machines are more suitable for scenarios that do not require high production volume or have long production cycles.

4. Cost comparison

Due to different equipment configurations, the investment cost of fully automatic metal ceiling tile machines is usually higher than that of semi-automatic metal ceiling tile machines. The equipment price of fully automatic suspended ceiling machines is relatively high, and its highly automated characteristics make the initial investment relatively large. However, this also means that in the long run, companies can recover this part of the investment by improving production efficiency and reducing labor costs.

In contrast, the initial investment cost of semi-automatic suspended ceiling machines is lower, which is suitable for companies with tight funds or in the start-up stage. However, due to its low degree of automation, it needs to rely on more manual support in long-term operation, resulting in relatively high labor costs.

Advantages of KINGREAL CEILING MACHINERY suspended ceiling machine

1. Hydraulic decoiler

KINGREAL CEILING MACHINERY's suspended ceiling machine is equipped with a hydraulic decoiler, replacing the traditional hand-cranked expansion method. The hydraulic expansion method can not only greatly reduce the labor intensity of the operation, but also save feeding time and improve production efficiency. More importantly, the hydraulic system can ensure the stability and safety of feeding, avoiding safety hazards caused by improper human operation.

2. A variety of supporting equipment is available

KINGREAL CEILING MACHINERY can also provide customers with other related equipment, such as fleece sticking machines, plate washing machines, etc., to further improve the comprehensive performance of the production line. By matching with the metal ceiling tile machine, a more efficient and accurate production process can be achieved. For example, the cloth sticking machine can help customers quickly stick fireproof cloth, and the sheet degreasing machine can clean the produced ceiling to ensure the quality of the finished product.

3. Diversified production

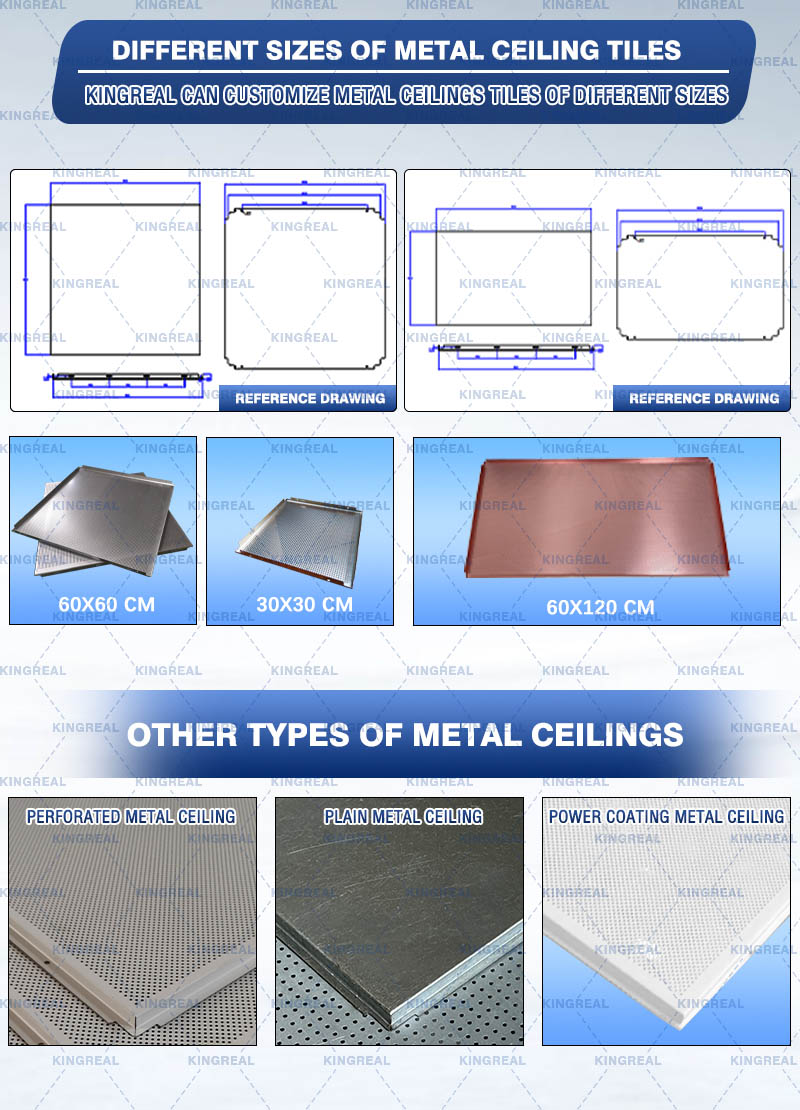

KINGREAL CEILING MACHINERY's metal ceiling tile machine can meet the production needs of ceilings of different types, sizes and materials. Whether it is 30x30cm, 60x60cm or 60x120cm in size, or different types of ceilings such as clip-in, lay-in, tegular, etc., it can be successfully completed through this production line. Moreover, this production line is also compatible with a variety of metal materials, such as GI steel or aluminum, to meet the production needs of different customers.

4. Customized solutions

Every customer's production needs and factory conditions are different. To this end, KINGREAL CEILING MACHINERY provides customized solutions and designs according to the actual needs of customers. Whether it is punching speed, punching die, or press die, KINGREAL CEILING MACHINERY will customize it according to the customer's drawings and specific requirements to ensure that the metal ceiling tile machine can fully meet the customer's production requirements.

Get the latest price? We'll respond as soon as possible(within 12 hours)