What's Advantages of Metal Ceiling Making Machine?

2025-01-19 16:32

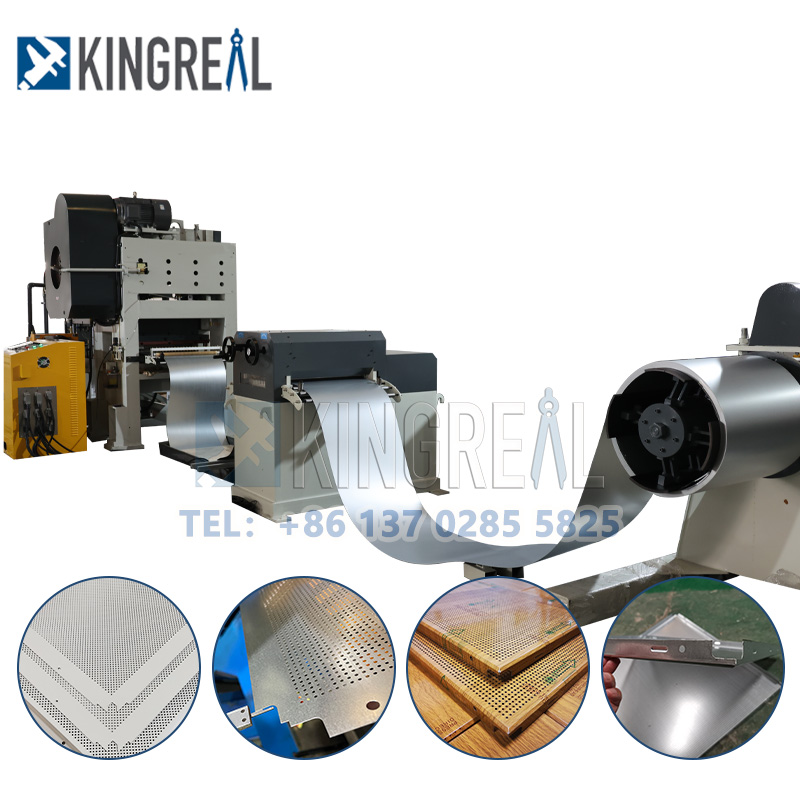

Definition of Metal Ceiling Making Machine

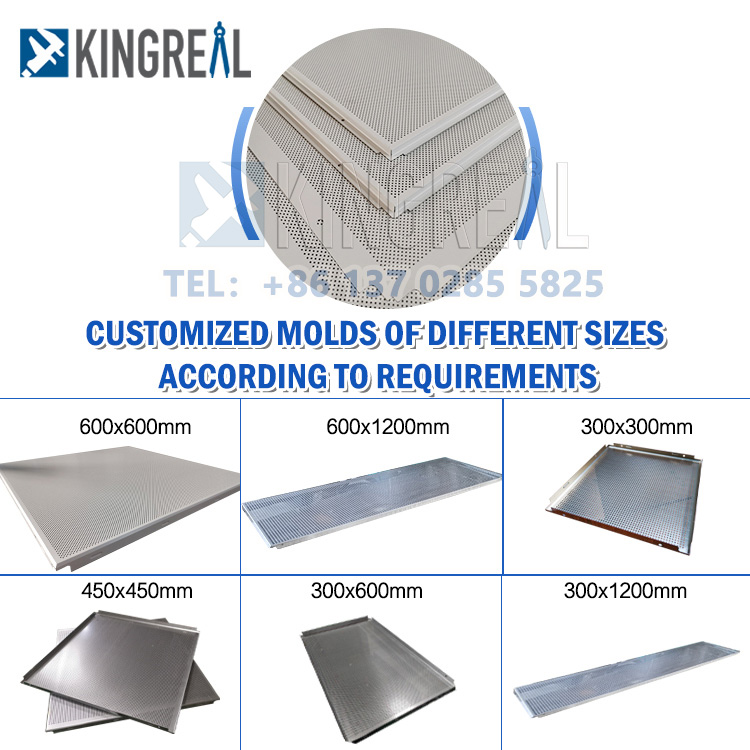

Metal ceiling panels production line can produce metal ceilings of different sizes (30x30cm, 60x60cm, 60x120cm, etc) and types (clip in, lay in, tegular, etc). KINGREAL CEILING MACHINERY can provide fully automatic and semi-automatic metal ceiling panels production lines for customers to choose.

KINGREAL CEILING MACHINERY's metal ceiling making machine has a fast production speed, and the production speed from unwinding to discharging is about 5-6 pieces of metal ceiling tiles per minute.

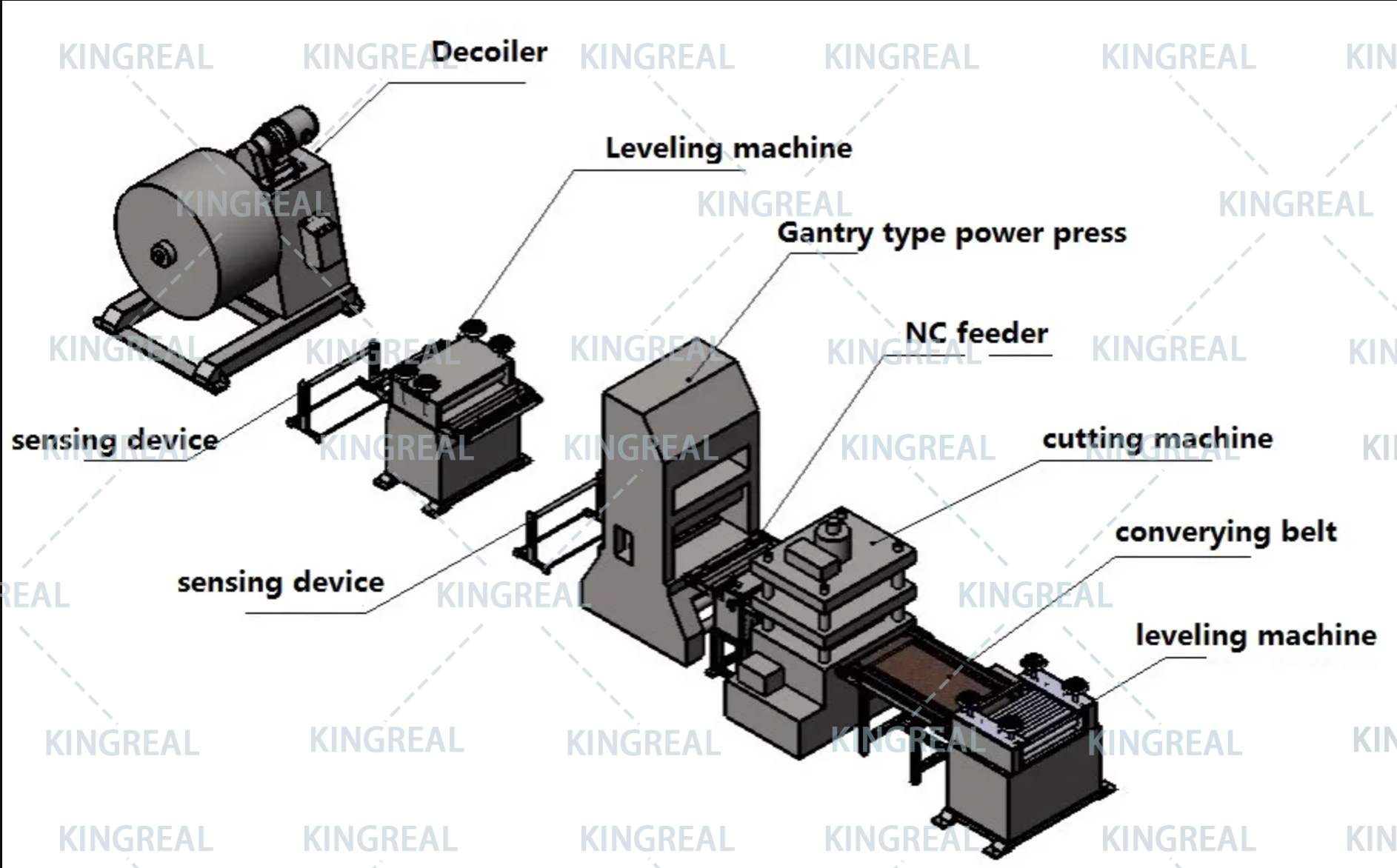

Main components of metal ceiling panels production line

Decoiler → Precision Straightener → Perforation Press → Servo Feeding Machine → Notching and Shearing Press → 2nd Precision straightener → Tiles Flipping Machine → Automatic Tiles Feeding Machine → Auto Bending Forming Press

- Decoiler:

It is used to automatically unwind the metal coil, with a maximum uncoiling width of 700mm. It uses a hydraulic drive system to ensure stable and efficient uncoiling.

- Precision Straightener:

Before the metal coil enters the punching process, it is leveled. It is equipped with 21 leveling rollers, 10 rollers on the upper part and 11 rollers on the lower part, which effectively eliminates the corrugation and unevenness of the coil and ensures the smooth progress of subsequent processes.

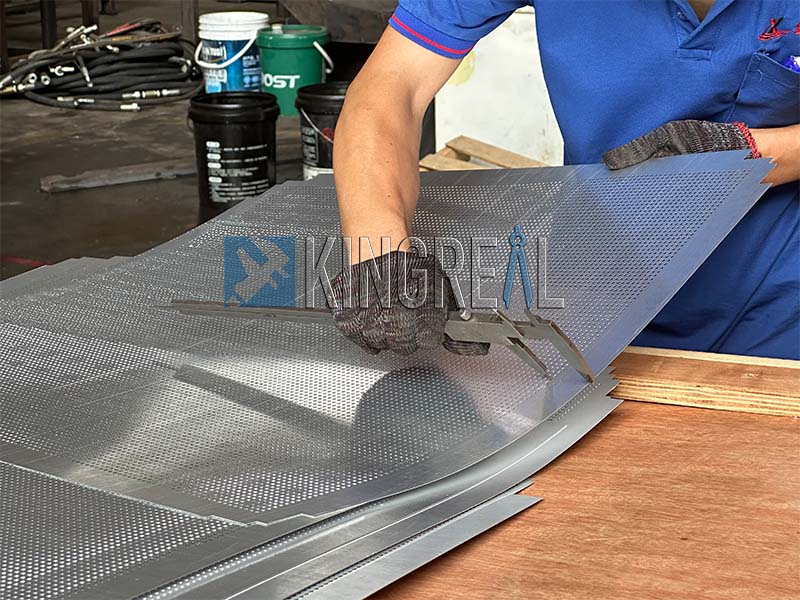

- Perforation Press (optional):

If you produce metal perforated ceilings, you need to punch the metal coils through a perforation press that can accurately punch holes to meet the design requirements of different ceilings.

- Servo feeder:

Automatically and accurately delivers metal coils to the next process, supports metal coils with a maximum width of 700mm, and has a feeding accuracy of ±0.02mm. It is equipped with a 3.0KW motor to ensure efficient and stable feeding.

- Notching and Shearing Press:

Used to cut off the four corners of the metal coil and cut it to ensure the neatness and standardization of the metal sheet.

- 2nd Precision Straightener:

After the punching process is completed, the metal sheet is flattened again to ensure the surface of the product is flat and ready to enter the next forming stage.

- Tiles Flipping machine:

Automatically flip the metal sheet 180 degrees without manual intervention, improve production efficiency and reduce worker operation risks.

- Automatic feeding manipulator:

Precisely feed the metal sheet into the forming press, effectively avoiding safety hazards in manual operation, and improving work efficiency and safety.

- Forming press:

The four corners of the metal sheet are formed by the press. By changing the mold, a production line can adapt to the production needs of different plate types and meet the processing requirements of diversified products.

Workflow of metal ceiling making machine

Decoiling - 1st Leveling - Perforation - Corner Cut - Conveyor - 2nd Leveling - Turnover Unit - Manipulator - Bending - Finished Tile

Advantages of KINGREAL CEILING MACHINERY metal ceiling panels production line

Customized service

KINGREAL CEILING MACHINERY metal ceiling panels production line can produce ceiling tiles and panels of different thicknesses, width ranges, production capacities and different raw materials.

Easy to operate

With the practical control panel, software and work adjustment of the metal ceiling making machine, it is very easy to use KINGREAL CEILING MACHINERY's metal ceiling panels production line.

Various types of metal ceilings

By changing the mold, one production line can produce different types of metal ceilings, such as clip in, lay in, tegular, etc. If you have special needs, welcome to result KINGREAL CEILING MACHINERY.

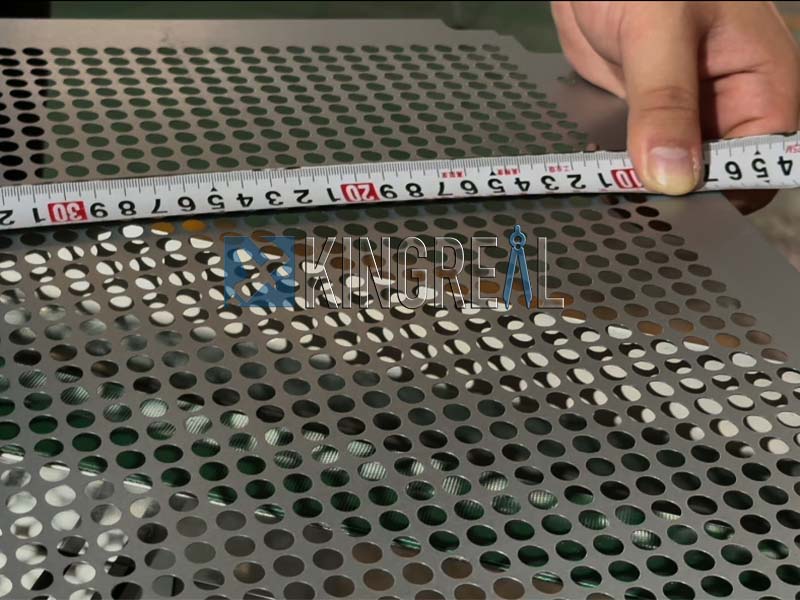

Finished product display

KINGREAL CEILING MACHINERY staff strictly control the manufacturing process of the metal ceiling making machine. The metal ceiling produced has no burrs, no scratches on the surface, high precision, and the error is within the range of ±0.1mm.

Get the latest price? We'll respond as soon as possible(within 12 hours)