What is a sheet metal straightener?

2025-01-14 11:47

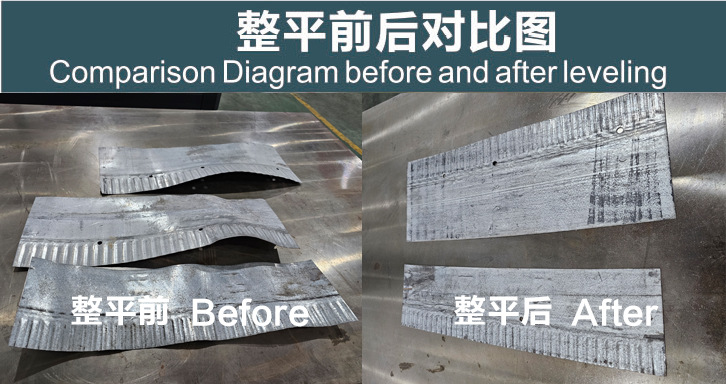

Definition of sheet leveler machine

A sheet leveler machine is a mechanical device used to level metal sheets, coils and other materials, aiming to make their surface flatness meet specific process requirements. By pressing, stretching, correcting and other means, the sheet metal straightener eliminates the unevenness of the metal material surface, ensuring that the material can maintain higher precision in subsequent processing, reducing errors and improving processing efficiency.

Sheet leveler machines usually apply uniform pressure to the material surface by adjusting the pressure size and distribution, leveling various materials such as metal sheets and plastic films to meet the specified flatness and precision requirements, thereby improving the effect of subsequent processing and the quality of the final product.

Importance of sheet metal straightener

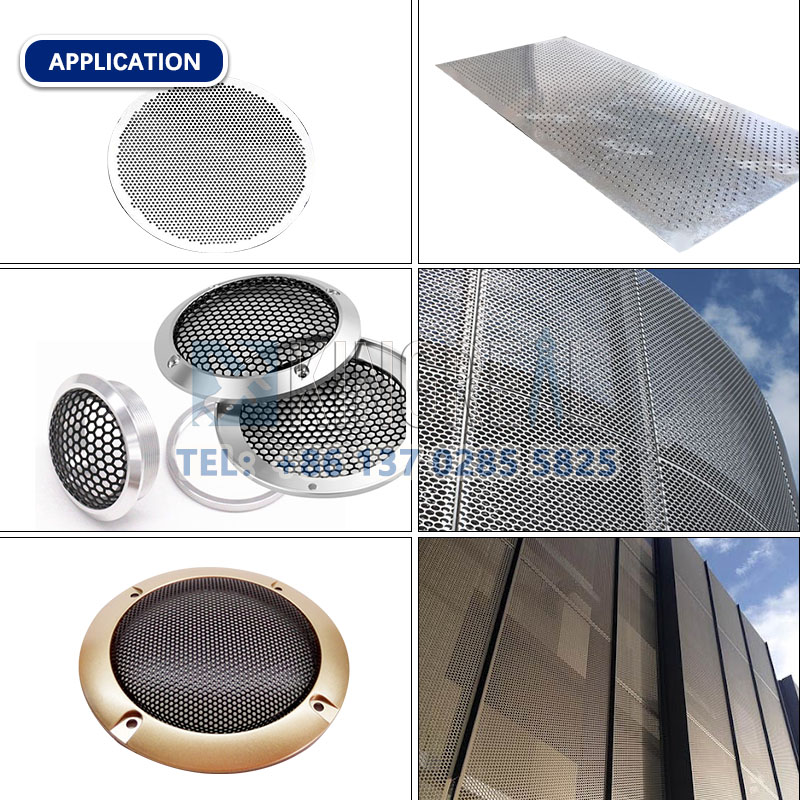

Sheet leveler machines are widely used in many industries, especially in the following areas:

1. Metal processing industry

Whether it is steel, aluminum, or copper, leveling can reduce subsequent processing errors. Sheet leveler machines improve the quality of finished products such as stamping, cutting, and bending by eliminating irregularities such as warping and bending of materials, and improve the overall efficiency of the production line.

2. Electronic and electrical manufacturing

Flat metal sheets are often used to manufacture electrical housings, circuit board brackets, etc. The flattened materials can meet the requirements of high-precision assembly and improve the appearance and performance of the products.

3. Automobile manufacturing industry

In the production of automobile body parts and interior parts, the flattened materials can ensure the molding accuracy of the parts, thereby helping to manufacture high-quality automobile products and improve the overall safety and aesthetics of the automobile.

Components of sheet leveler machine

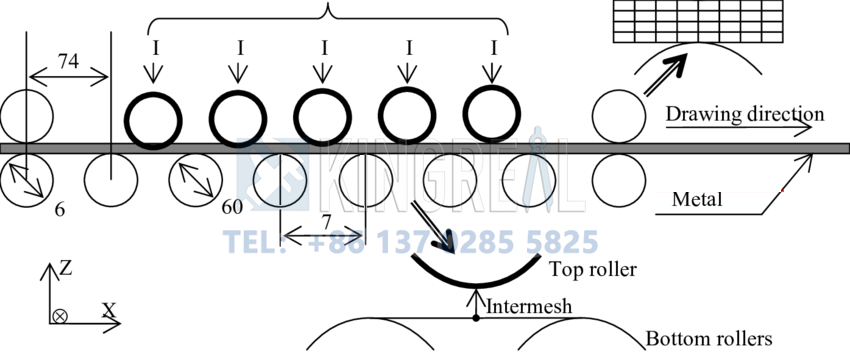

1. Roller group

The roller group is the core component of the sheet metal straightener, usually composed of multiple high-precision steel rollers. The roller surface is smooth and hard, and some are also hard chrome-plated to enhance wear resistance and corrosion resistance, ensuring long-term stable operation.

2. Transmission system

The transmission system is responsible for transmitting power to the roller and driving the roller to rotate. Generally, it includes motors, reducers, couplings, chains, sprockets and other components to ensure that the rollers run at a uniform and stable speed and that the materials are transported smoothly.

3. Adjustment mechanism

Used to adjust the gap and pressure between the rollers to ensure the leveling effect. The adjustment mechanism is usually composed of handwheels, screws, nuts and other components. The operator can make fine adjustments according to the characteristics of the material to obtain the ideal leveling effect.

4. Frame

The frame provides a stable support for the sheet metal straightener. It is usually welded with high-strength steel to ensure the stability of the equipment during operation and avoid the leveling accuracy affected by vibration and unstable factors.

KINGREAL CEILING MACHINERY sheet leveler machine

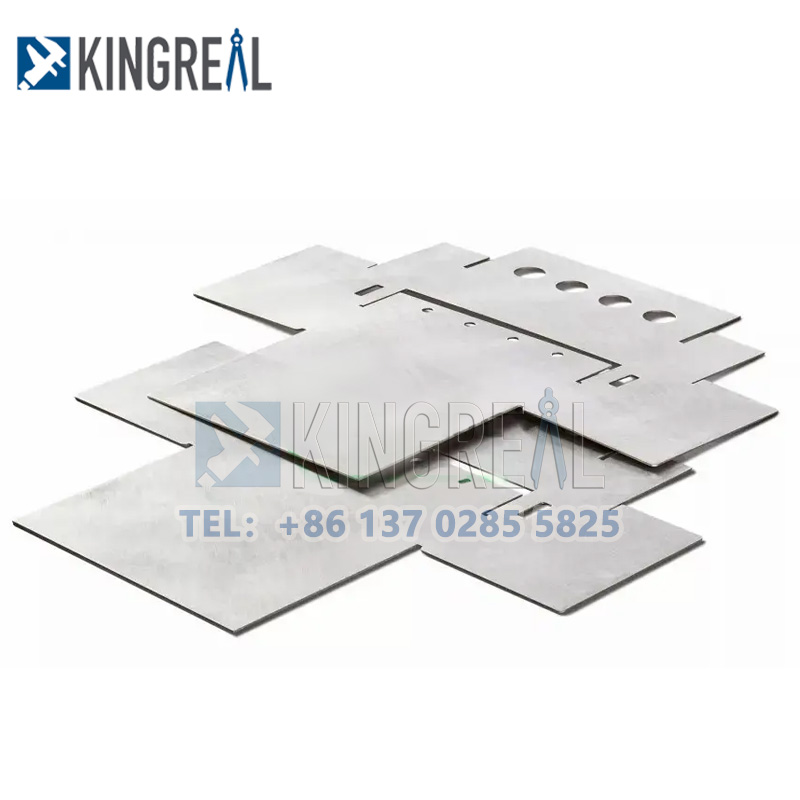

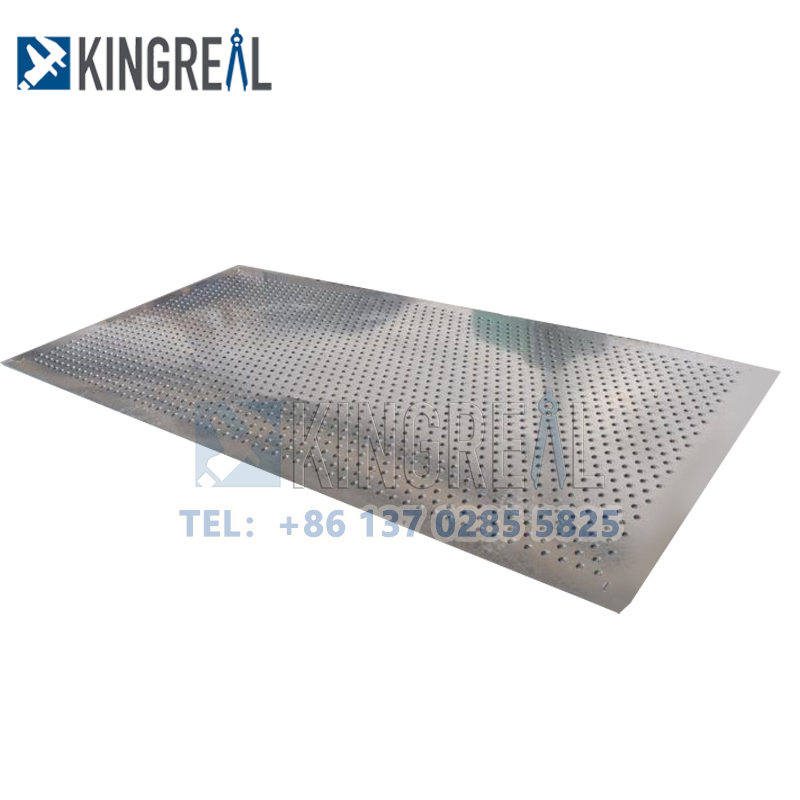

KINGREAL CEILING MACHINERY is a professional sheet leveler machine manufacturer, providing leveling treatment for a variety of metal materials (such as metal sheets, perforated mesh, metal sticks, metal parts, etc.). KINGREAL CEILING MACHINERY high-precision leveling machine can release the internal stress of the material, so that the flatness of the leveled product reaches a very high precision and fits the marble platform completely. It has the following advantages:

1. Meet industry needs

The construction, automobile, aerospace, home appliance and other industries have strict requirements on the accuracy and surface flatness of metal materials. The sheet metal straightener can meet the needs of these industries and is the basic equipment to ensure smooth production.

2. Ensure product quality

Through leveling, the surface of metal materials is smoother and more uniform, reducing the problem of uneven deformation in subsequent processing. This makes the leveled metal sheet more suitable for welding, painting and other processes, improving the quality and appearance of the final product.

3. Reduce production costs

The sheet metal straightener can effectively avoid processing errors caused by deformation of metal materials and reduce scrap rates. By improving the utilization rate of materials, companies can save costs and increase overall profits.

4. Improve production efficiency

The sheet leveler machine can quickly remove the warping and bending of the metal sheet, avoiding the tedious process of manual trimming, thereby improving the overall efficiency of the production line. The leveled metal material can be directly used for subsequent processing to reduce unnecessary waste.

5. Improve processing accuracy

The sheet metal straightener uses high-pressure rollers, rollers and other technical means to achieve precise leveling of metal sheets and reduce processing errors caused by sheet deformation. This is especially important for industries with extremely high precision processing requirements (such as aviation, electronic manufacturing, etc.).

6. Promote technological innovation

With the development of science and technology, sheet leveler machines are also constantly innovating. The automation and intelligence of modern sheet leveler machines are constantly improving. They can automatically adjust the leveling force and speed according to different materials and production requirements, improve production flexibility, and promote the advancement of equipment manufacturing technology and the upgrading of related industries.

Other types of machines in KINGREAL CEILING MACHINERY

In addition to sheet leveler machines, KINGREAL CEILING MACHINERY also provides a variety of high-quality mechanical equipment to meet the needs of different industries, including:

- Metal Ceiling Production Line

- Linear Strip Ceiling Machine

- Metal Ceiling Carrier Machine

Get the latest price? We'll respond as soon as possible(within 12 hours)