What's a perforated metal sheet making machine?

2025-01-29 14:04

Definition of

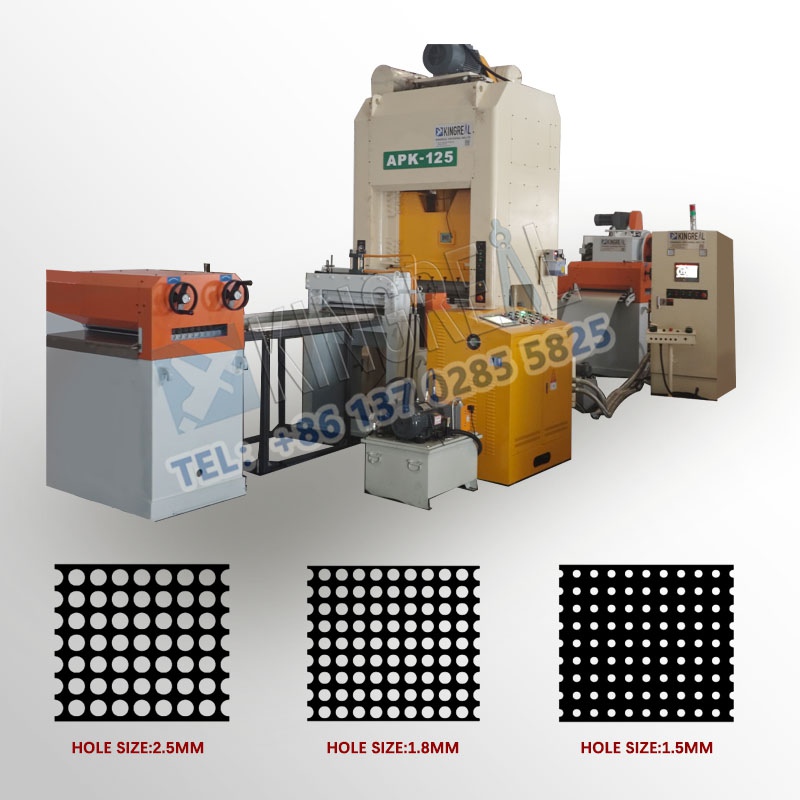

perforated metal sheet making machine

KINGREAL CEILING MACHINERY is a manufacturer specializing in the manufacture of metal processing equipment. It can provide various types of metal sheet perforated machines, which are widely used in the production of punched metal plates of various materials. By replacing the punching die, KINGREAL CEILING MACHINERY's perforated metal sheet making machine can flexibly produce holes of different shapes and apertures to meet the diverse needs of customers. Common punching shapes include round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes and cross holes. If customers have special punching needs, they only need to provide drawings, and KINGREAL CEILING MACHINERY's engineering team will design a customized metal sheet perforated machine solution based on the customer's actual production requirements. |  |

Components of perforated punching machine

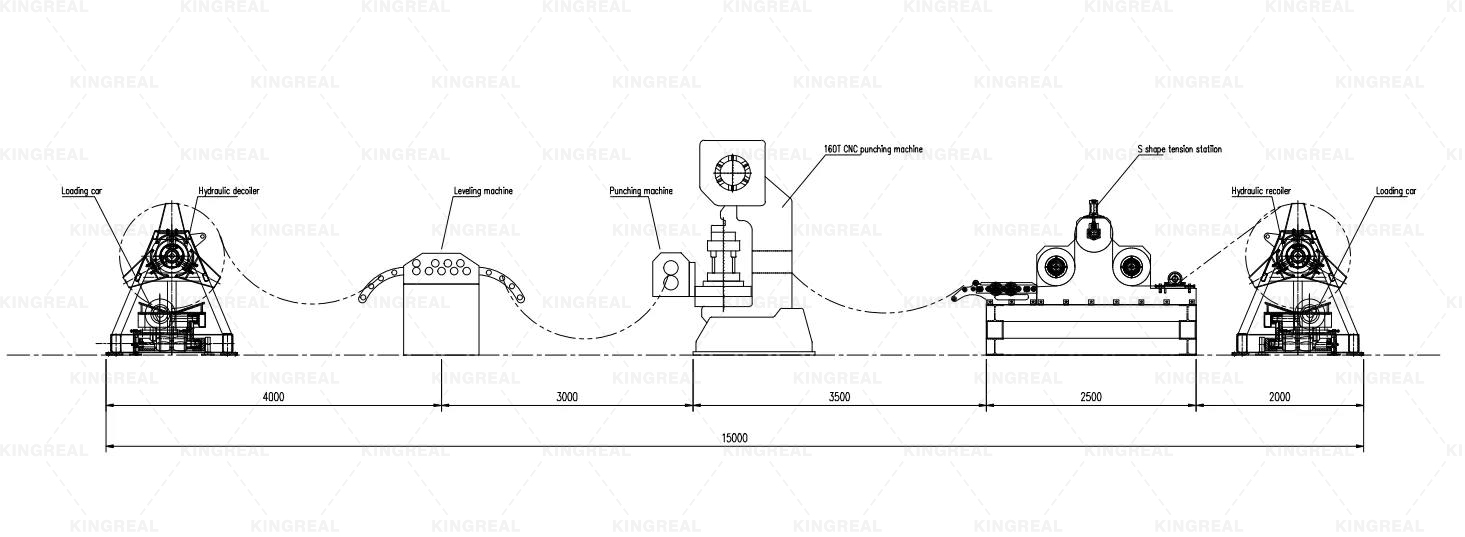

KINGREAL CEILING MACHINERY's perforated metal sheet making machine consists of the following key parts, each of which has been carefully designed to ensure the efficiency and stability of the entire production line:

Decoiler

Used to unwind the metal coil and feed it into the perforated punching machine to ensure that the material enters the next process at a stable speed.

Precision Straightener

Leveling the metal sheet to ensure the surface of the sheet is flat and smooth, providing good processing conditions for subsequent punching and shearing processes.

Punching station

The core part, through the customized punching die to punch the metal plate, can achieve a variety of shapes and specifications of punching needs.

Working Process of

perforated metal sheet making machine

KINGREAL CEILING MACHINERY's perforated metal sheet making machine adopts a modular design, the workflow is clear and smooth:

1. Uncoiling: The metal coil is unrolled through the decoiler and conveyed to the production line.

2. Leveling: The leveling machine flattens the metal sheet to eliminate the internal stress of the material.

3. Punching: The sheet enters the punching station and is punched according to the shape and aperture of the preset die.

4. Finished product collection: The finished products after punching are neatly collected and prepared for subsequent packaging or transportation.

Video About Metal Sheet Perforated Machine

Advantages of KINGREAL CEILING MACHINERY

perforated metal sheet making machine

Diversified metal sheet perforated machine manufacturing solutions

KINGREAL CEILING MACHINERY provides a variety of perforated metal sheet making machines, including metal ceiling perforation lines, coil perforated rewinding production lines and metal sheet coil perforated cutting production lines. Customers can freely choose the appropriate solution according to their own production needs.

Customized punching dies for metal sheet perforated machine

KINGREAL CEILING MACHINERY's engineering team can design customized punching dies according to the drawings provided by customers, ensuring that the dies are fully matched with customers' production needs, thereby improving production efficiency and product quality.

High flexibility for metal sheet perforated machine

KINGREAL CEILING MACHINERY's metal sheet perforated machine has strong flexibility in production details. Whether it is the thickness of the plate or the speed of punching, KINGREAL CEILING MACHINERY can accurately set the parameters of the metal sheet perforated machine according to the actual needs of customers to meet personalized production needs.

Excellent quality for metal sheet perforated machine

KINGREAL CEILING MACHINERY uses advanced technology in the manufacturing process of the perforated punching machine, selects high-quality raw materials, and conducts strict quality tests on each device. The punching line it produces runs smoothly, has a fast punching speed, high hole consistency, and a long service life of the equipment, with extremely high cost performance.

KINGREAL CEILING MACHINERY's featured

perforated metal sheet making machine

Metal ceiling perforation line

KINGREAL CEILING MACHINERY's metal ceiling perforation line is designed specifically for the metal ceiling industry. It can efficiently produce metal ceilings with various patterns and hole types, and is widely used in the field of architectural decoration.

Metal sheet perforated machine

This production line integrates punching and shearing. The sheet metal perforation machine can complete the punching and cut-to-length processes.

KINGREAL CEILING MACHINERY's coil to coil perforation line is suitable for rewinding the punched metal sheets for easy transportation and storage.

Get the latest price? We'll respond as soon as possible(within 12 hours)