300MM U Baffle Ceiling Roll Forming Line

300mm U Baffle Ceiling Roll Forming Line is one of the most successful customized projects in KINGREAL CEILING MACHINERY. Our customer, Douglas Group, has a demand for special size u baffle ceiling production. KINGREAL CEILING MACHINERY's technical team improved and adjusted the production technology of u baffle ceiling, and finally successfully customized a machine that can stably produce 300mm u baffle ceilings. If you have a need for a customized machine, please feel free to contact us!

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About 300MM Ceiling Baffle Machine

KINGREAL CEILING MACHINERY Successful Cases in Global

With years of penetration into the metal ceiling equipment market, KINGREAL CEILING MACHINERY has stocked many successful cases and localized technical support experience.

Description of U Baffle Metal Ceiling Production Line

1. Specially Design

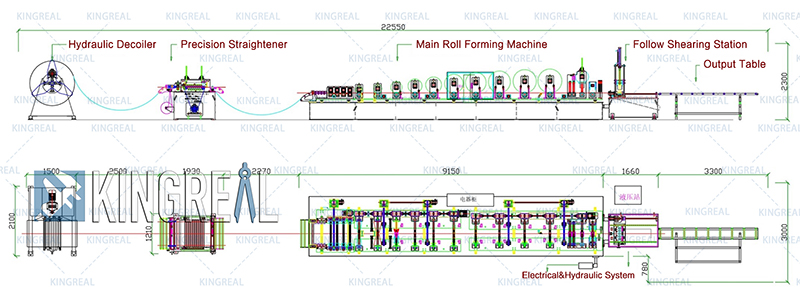

KINGREAL CEILING MACHINERY u baffle machine is one of our most distinctive products. This metal ceiling production line is specially designed and manufactured for Hunter Douglas Group to produce big size baffle ceilings up to 300mm in height.Components of the line: Hydraulic Decoiler, Precision Straightener, Main Roll Forming Machine, Hydraulic Follow Shearing Station, Product Output Table and Electrical Control System.

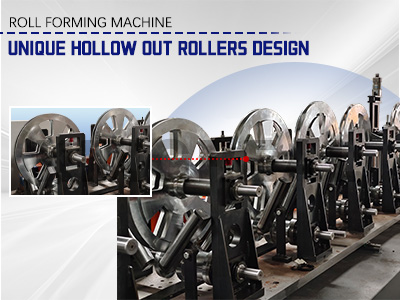

2. Hollow Structure

KINGREAL CEILING MACHINERY's R&D Department designed a hollow structure for a 300mm U baffle ceiling machine to reduce the problem of indentation caused by the weight of the rollers. This technology is particularly suitable for machines that produce 200mm+ baffle ceilings. The hollow rollers are made of high-quality steel to ensure they are in good condition and with durability under long time working.

3. High Adaptability

KINGREAL CEILING MACHINERY uses Cr12MoV mold steel to build rollers for 300mm u baffle making machines to ensure a precision roll forming procedure. Also, This production line can produce baffle ceilings with different sizes from 30mm to 300mm height maximum.

Only need to input parameters in the operating system, the programmable PLC control system will adjust accordingly.

4. Follow Shearing

KINGREAL CEILING MACHINERY equipped this 300mm u baffle machine with a high-quality hydraulic follow shearing station.

With a servo motor from industry-leading brand Yaskawa and a Cr12 steel-made blade, the shearing station can accurately and precisely cut products to length. Also, the station can cut products of different sizes by changing molds.

5. Customized Service

This 300mm u baffle machine can provide products in different sizes, it can also provide acoustic baffles by customization of the whole production line. KINGREAL CEILING MACHINERY has strict quality control regulations for both the production line itself and the final products to ensure they work well for KINGREAL CEILING MACHINERY's clients.

6. Sell Globally

This baffle ceiling machine was manufactured in early 2019, and then inspected, tested and approved by Hunter Douglas Group's Indian Section. Which is an excellent example of KINGREAL CEILING MACHINERY high-quality machining. In 2023, this production line was manufactured again and sold to South America.

KINGREAL CEILING MACHINERY is always ready to introduce this product to more customers globally.

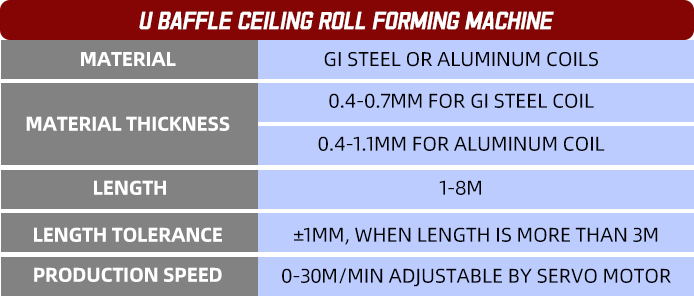

Technical Specification of Baffle Ceiling Roll Forming Machine

Working Process of U baffle Ceiling Roll Forming Line

Hydraulic Decoiler -- Precision Straightener -- Main Roll Forming Machine -- Follow Shearing Station -- Output Table

Quality Inspection

KINGREAL CEILING MACHINERY often receives high praise from customers for the baffle ceilings manufactured by KINGREAL CEILING MACHINERY u baffle machine. Customers have said that these ceilings are perfectly adapted to their needs in terms of size, with the front and rear errors controlled within ±0.1mm. This precise dimensional control not only reflects the high-level technology of KINGREAL CEILING MACHINERY's baffle ceiling machine, but also is a strong proof of KINGREAL CEILING MACHINERY's commitment to quality.

Customer feedback mentioned that KINGREAL CEILING MACHINERY's baffle ceilings can be seamlessly connected with other components during installation, greatly improving construction efficiency and reducing rework and material waste caused by dimensional incompatibility. This excellent adaptability makes baffle ceilings perform well in various application scenarios and has won wide recognition in the market.

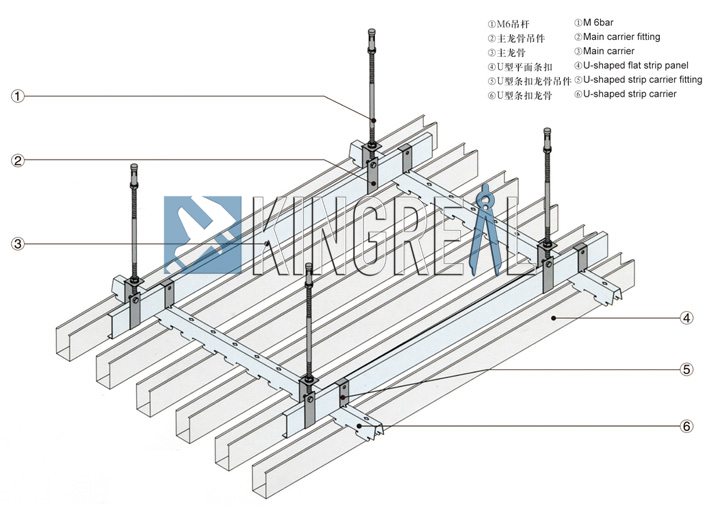

Baffle Ceiling Installation Drawing

The baffle ceiling produced by KINGREAL CEILING MACHINERY baffle ceiling machine has an open view, ventilation, air permeability, and its lines are bright and neat, with distinct layers. After installation, the whole space has a harmonious and soft three-dimensional sense of lines, reflecting a simple and clear modern style. Aluminum baffle ceiling is an interior decoration product, which is beautiful, durable and safe, and is deeply loved by people.

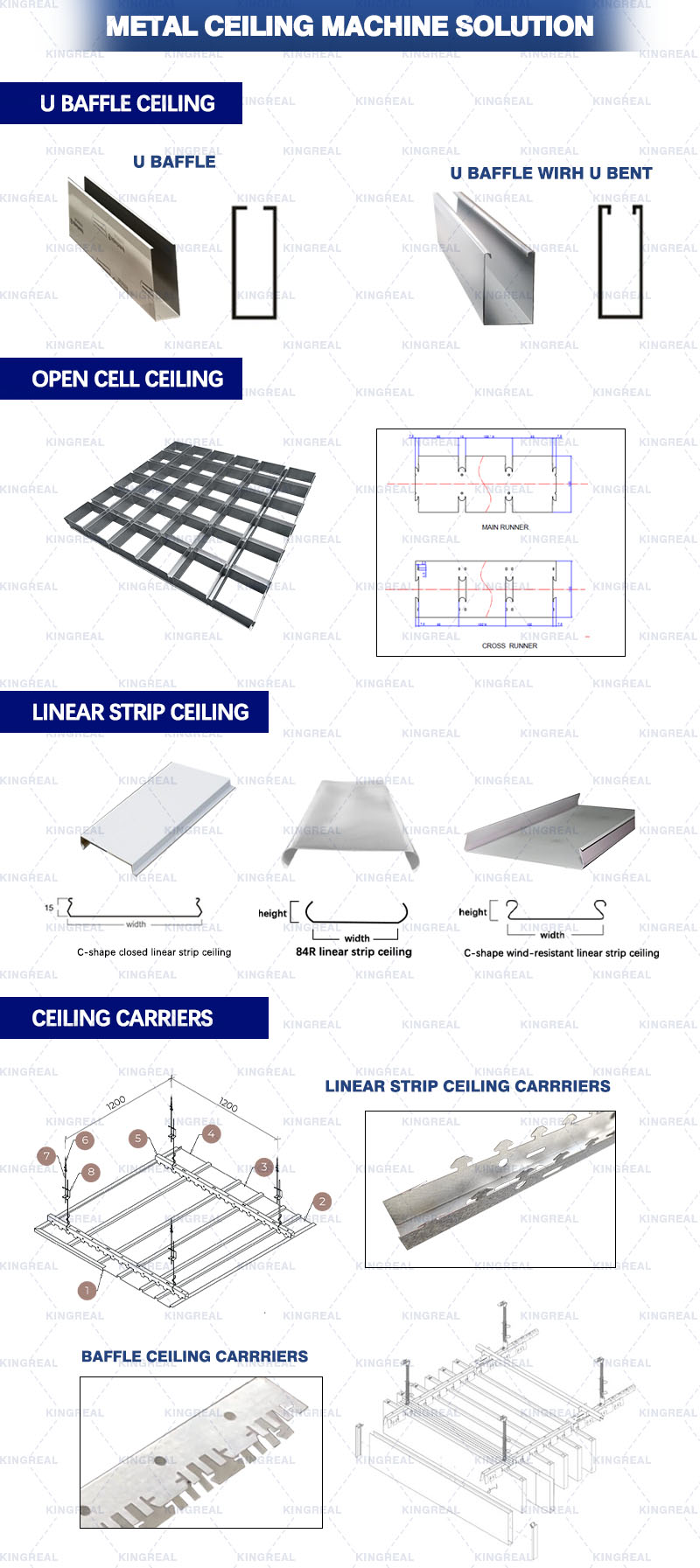

Complete Metal Ceiling Machine Solution

With more than 20 years of experience in the metal ceiling manufacturing market, KINGREAL CEILING MACHINERY has not only accumulated rich experience in the field of baffle ceiling making machines, but the successful sales of the metal ceiling making machines have also earned KINGREAL CEILING MACHINERY a good reputation around the world:

1. Open Cell Ceiling Making Machine

2. Linear Strip Ceiling Roll Forming Machine

3. Metal Ceiling Carriers Making Machine for Baffle Ceiling and Linear Strip Ceiling

Technology Support

As a professional manufacturer of baffle ceiling making machines in China, KINGREAL CEILING MACHINERY has been in design - production - installation - after-sales for more than 20 years. KINGREAL CEILING MACHINERY is able to customize production solutions according to customer's drawings and specific parameter requirements.

After you order, KINGREAL CEILING MACHINERY's technical team will test the machine in an effort to ensure every mechanical and electrical part is in perfect condition.

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL CEILING MACHINERY warmly welcomes customers to visit KINGREAL CEILING MACHINERY factory and communicate with us!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)