Fully Automatic Metal Ceiling Perforation Line

This fully automatic metal ceiling perforation line can be used with multiple ceiling materials and perforation patterns. According to your different ceiling panel perforation needs, KINGREAL CEILING MACHINERY is able to customize the ceiling panel perforated machine.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Fully Automatic Metal Ceiling Perforation Line

Successful Customized Cases

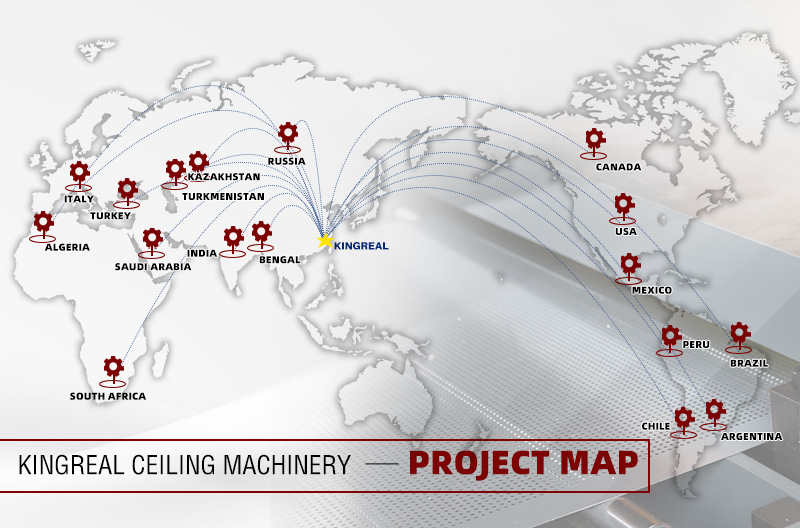

Metal ceiling perforation line is KINGREAL CEILING MACHINERY's featured machine. KINGREAL CEILING MACHINERY's perforated sheet making machine has been sold to countries around the world, with project cases in Brazil, Greece, UAE and other countries. Therefore, KINGREAL CEILING MACHINERY engineers have a deep understanding of the parameter requirements of metal ceiling perforation lines in various countries.

Description of Metal Ceiling Tile Perforation Machine

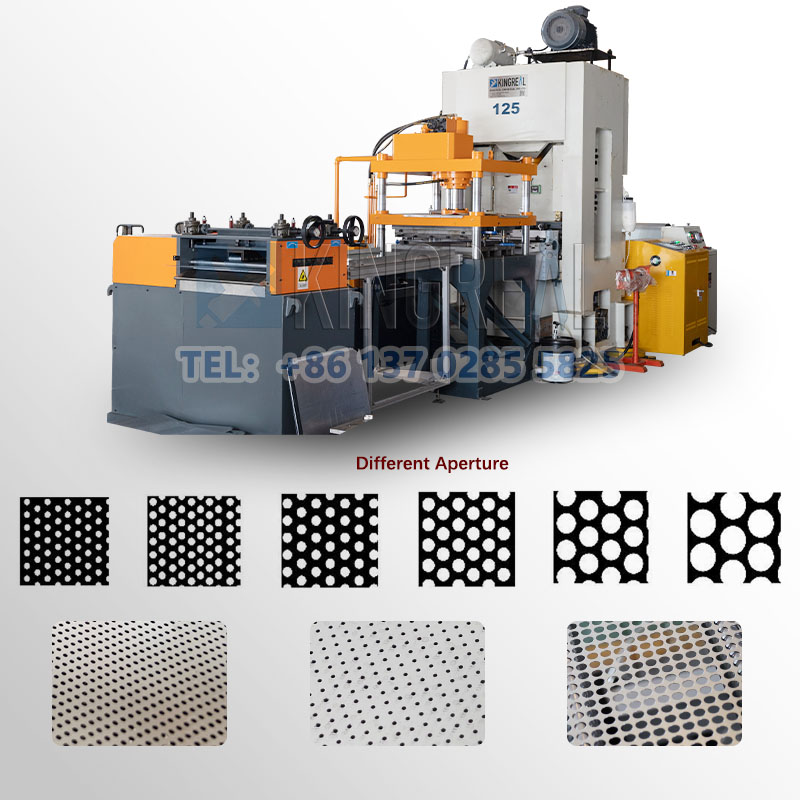

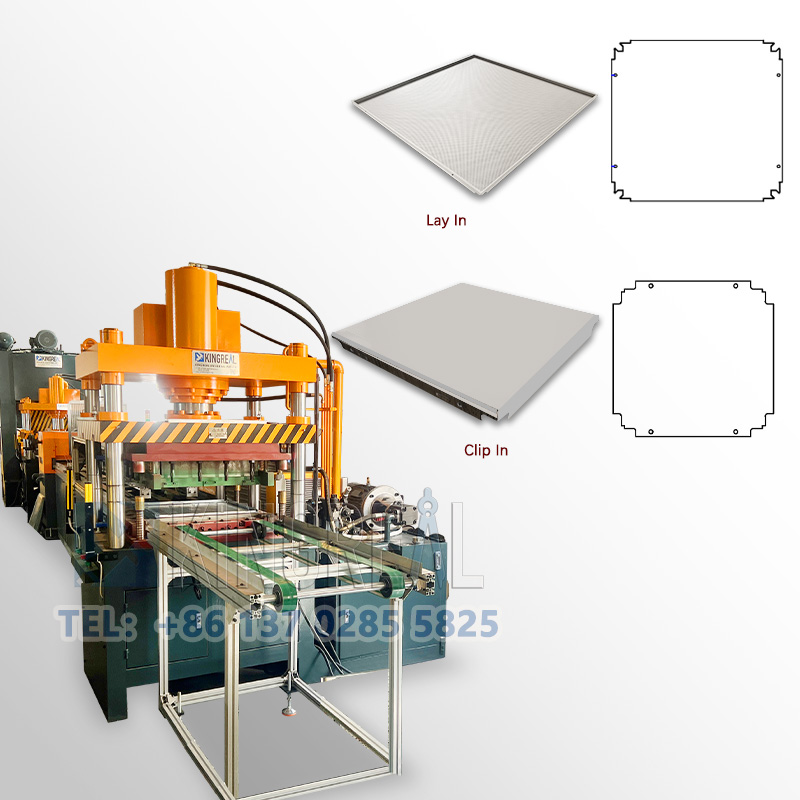

KINGREAL CEILING MACHINERY Metal Perforated Sheet Making Machine is a kind of machinery and equipment specially used for processing ceiling punching, mainly including decoiler, leveler, 125 Ton perforated punching machine and notching and shearing machine, which can meet different needs of customers.

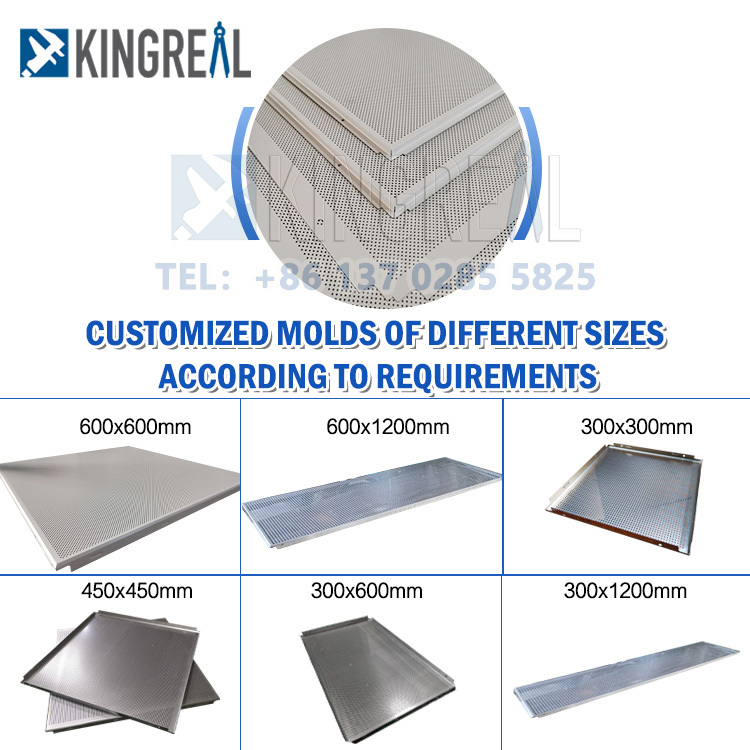

KINGREAL CEILING MACHINERY can provide the fully automatic metal ceiling perforation line for producing metal ceiling tile with various sizes, such as 30X30 cm, 60X60 cm, 60X120 cm and so on.

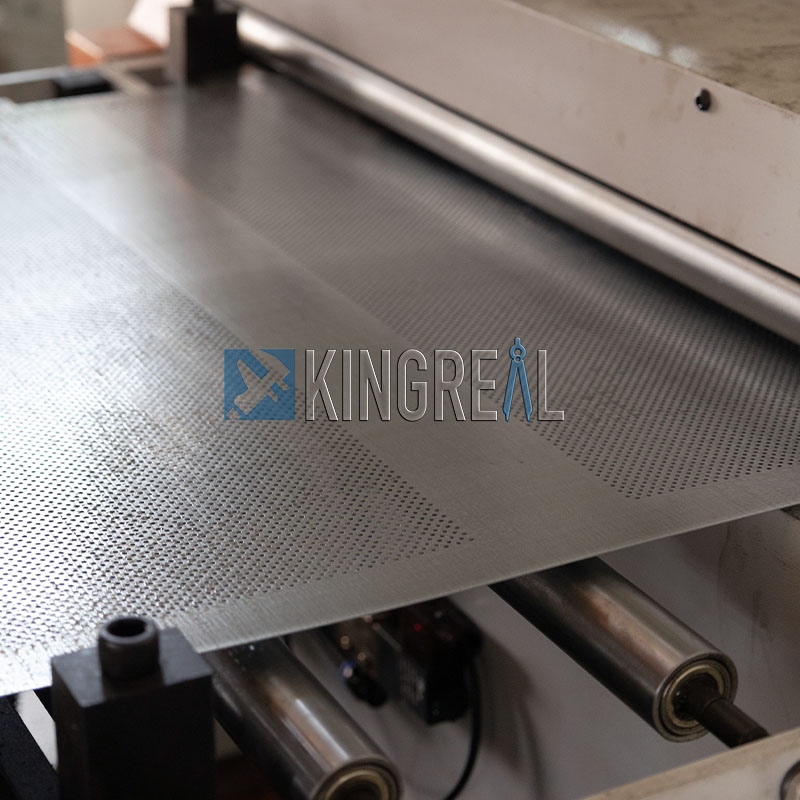

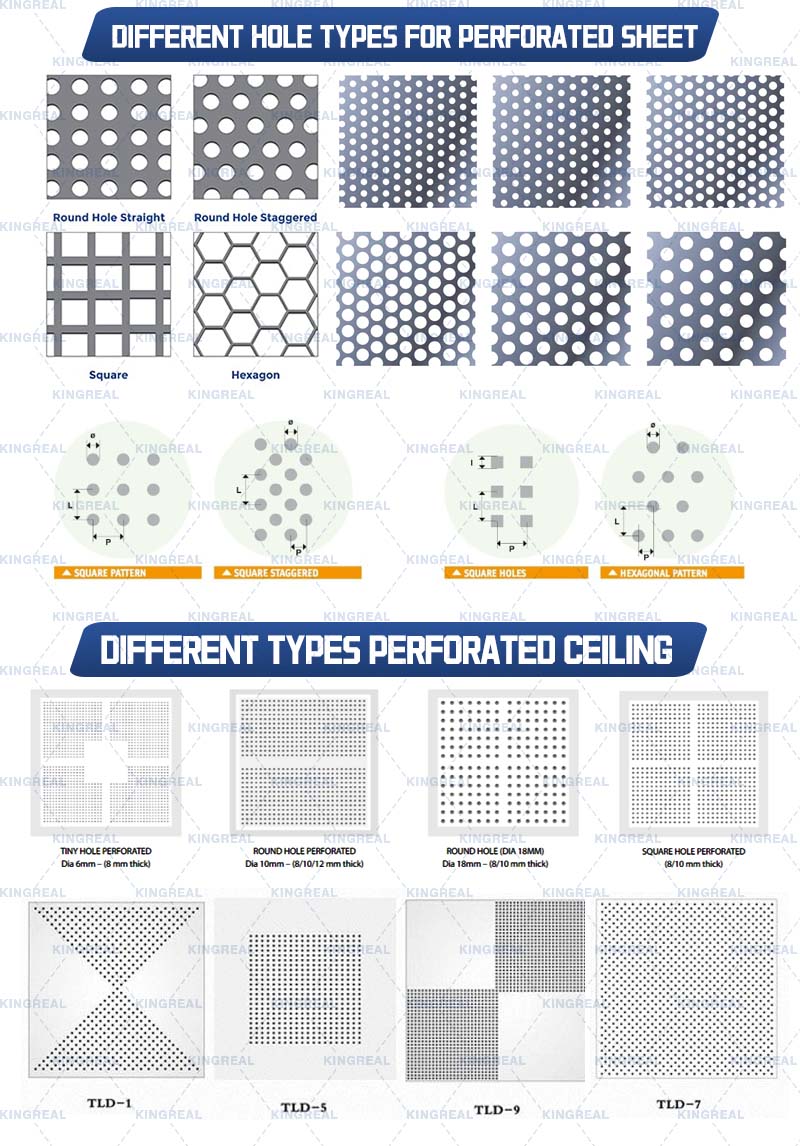

The punching press is a high-speed type, can give 150-180 strokes per minute, perforation diameter can be 1.8mm or 2.5mm which are popular, KINGREAL CEILING MACHINERY also accepts rectangular perforation or other shapes. Both aluminum and Gi steel materials are compatible with KINGREAL CEILING MACHINERY production line, KINGREAL CEILING MACHINERY also can offer customized service, KINGREAL CEILING MACHINERY can provide a suitable metal ceiling panel perforation line manufacturing plan according to your sheet metal perforating requirements, so do not need to worry.

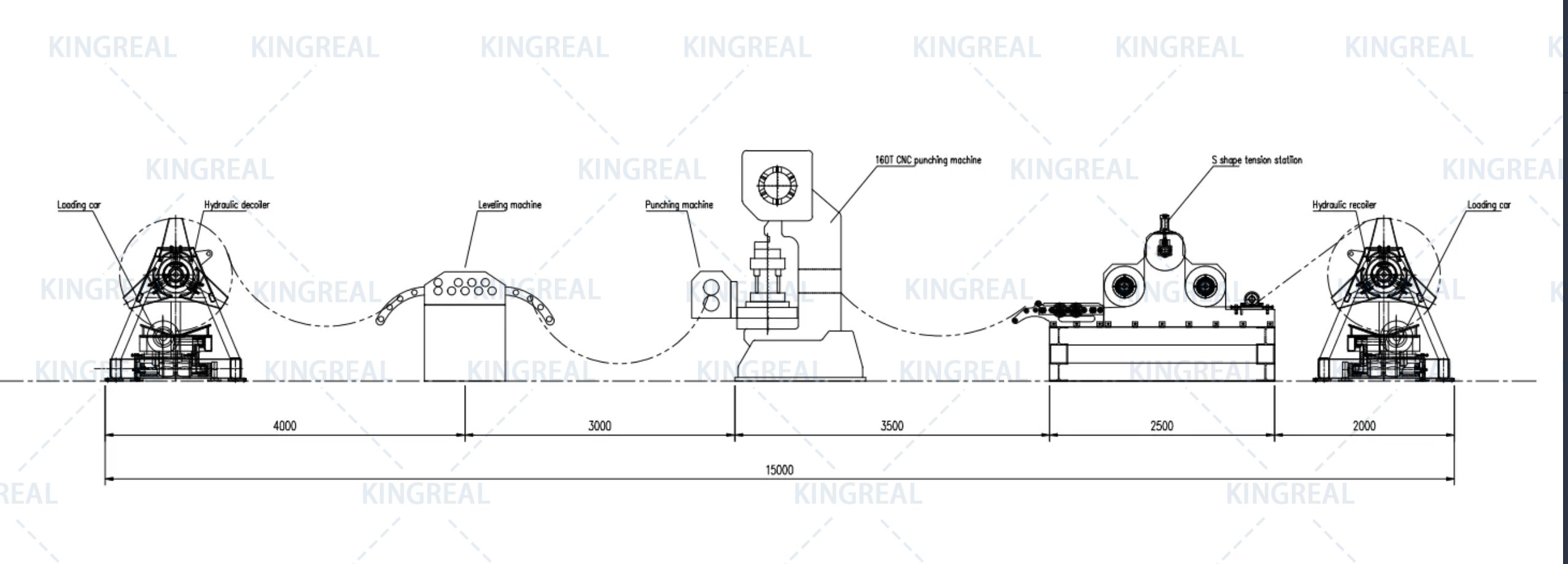

Working Process

Uncoiling → Leveling→ Perforated Plate → Hydraulic Notching & Shearing Machine → 2nd Leveling → Products Out Put or Other Processing

Main Features of Sheet Metal Punching Machine

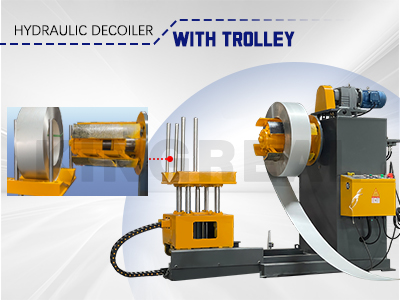

| Hydraulic Decoiler ● To respond to changing demands, KINGREAL CEILING MACHINERY has a hydraulic decoiler and manual decoiler with an integrated hydraulic core expansion system. For more, there is an optional trolley for full-automatic metal loading. |

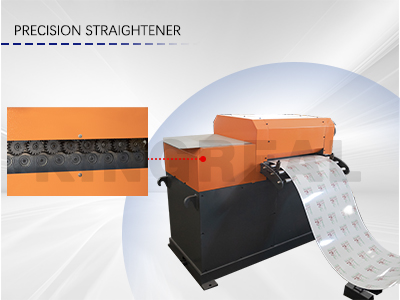

| High Precision Straightener ● The ceiling panel perforated machine provides a high- precision 21rollers straightener. To ensure straightness of perforated metal panels, KINGREAL CEILING MACHINERY doubled the number of precision rolls. As a result, finished perforated metal panels have higher precision. Leveling rollers, which are made of 40Cr round bars, were thermal refined, quenched at high frequency, electroplated twice and accurately ground. They are smooth, without scratches, their hardness is above HRC62,and regulated by 4 threaded rods. |  |

| Self-developed Software & Multi Language Support ● KINGREAL CEILING MACHINERY metal perforated sheet making machine has integrated self-developed software, which is more professional and can fully perform its functions. In addition, KINGREAL CEILING MACHINERY is able to provide a multi-language operation interface, including English, Russian, Spanish and so on. This makes KINGREAL CEILING MACHINERY machines easy to operate, more user-friendly and provides a better user experience. |

Automatic Metal Ceiling Perforation Line

KINGREAL CEILING MACHINERY's fully automated perforated sheet making machine consists of a variety of precision components such as decoiler, leveling machine, punching machine, etc., to build an efficient and intelligent production line. This advanced fully automated metal ceiling perforation line not only significantly improves production efficiency, but also effectively liberates manpower, making the production process smoother.

Different Tons of Sheet Metal Punching Machine for Option

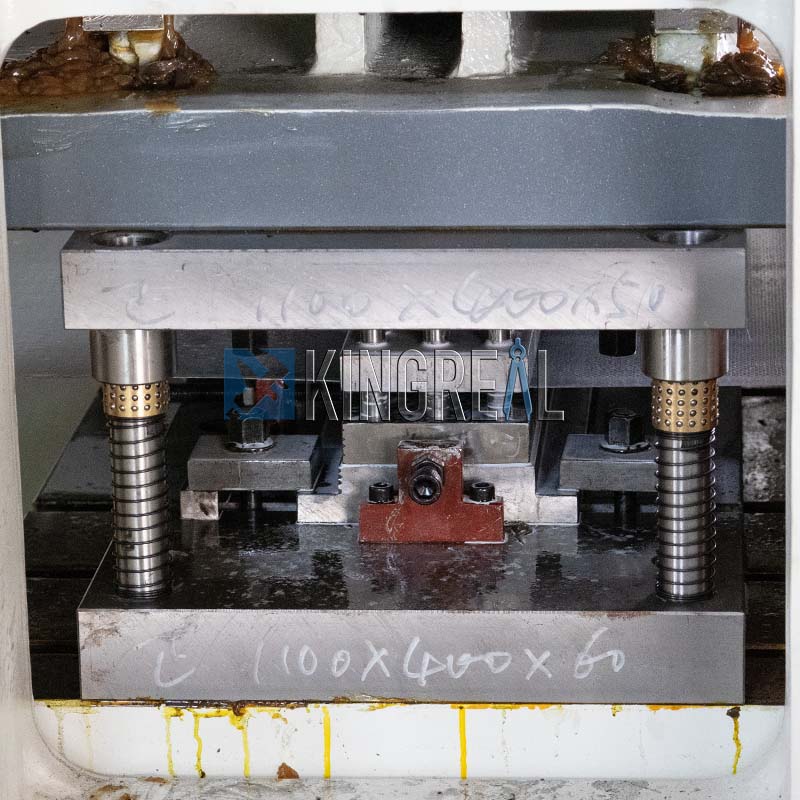

KINGREAL CEILING MACHINERY has been deeply involved in the metal processing machinery industry for more than 20 years and has a mature technical system. KINGREAL CEILING MACHINERY can customize suitable perforated ceiling production line according to different metal plate perforation needs of customers. The following two sheet metal punching machines are common configuration models of metal ceiling panel punching lines:

|  |

| 125 Ton Perforated Punching Machine ◆SPM: 150-180min ◆Max. Die Height: 400mm ◆Die Height Adjustment: 50mm | 160 Ton Perforated Punching Machine ◆SPM: 160-220min ◆Max. Die Height: 400mm ◆Die Height Adjustment: 50mm |

KINGREAL Can Offer a Complete Perforated Ceiling Systems

In addition to metal ceiling tile perforation machines, KINGREAL CEILING MACHINERY can also provide various types of metal ceiling tile production lines, such as 30x30cm aluminum ceiling tile production line, 60x60cm metal ceiling tile production line, 60x120cm aluminum ceiling tile production line, etc. And KINGREAL CEILING MACHINERY can also provide a metal ceiling tile production line for clip in ceiling, aluminum ceiling tile production line for lay in ceiling, metal ceiling tile production line for tegular ceiling. By combining these two machines, we can provide customers with a complete perforated ceiling solution.

|  |  |

| 30x30cm metal ceiling tile production line | 60x60cm aluminum ceiling tile production line | 60x120cm metal ceiling machine |

What Types Can the Ceiling Tile Perforation Machine Produce?

KINGREAL CEILING MACHINERY perforated sheet making machine can realize punching out different types and apertures of perforated ceilings on one production line by replacing the punching die. Common punching shapes include round hole straight, square, round hole staggered, hexagon, etc.

Installation Service

In order to help KINGREAL CEILING MACHINERY's customers solve machine installation problems, KINGREAL CEILING MACHINERY will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL CEILING MACHINERY will arrange for engineers to go abroad to install the machine at the customer's place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)