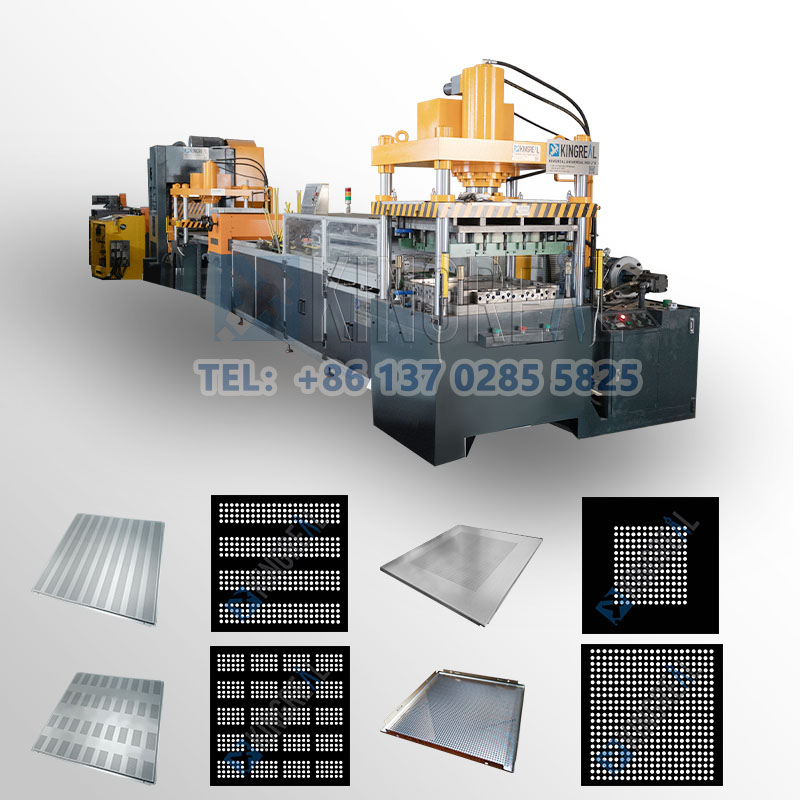

High Speed 60X60CM Metal Ceiling Tiles Machine

KINGREAL CEILING MACHINERY High Speed Full Automatic Metal Ceiling Production Line is one of our most featuring products.

This suspended metal ceiling production line can proudce 60*60CM metal ceiling tile full automatically with high speed perforation.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video Display About 60x60CM Ceiling Panel Production Line

Suspended Ceiling Pannel Making Machine Successful Projects in Global

This is the metal ceiling production line sent to the Saudi Arabian customer's factory. In order to meet the actual production needs of the customer, KINGREAL CEILING MACHINERY equipped the customer with a powder coating line.

The flat powder spraying production process of the metal ceiling includes automatic forming, placing in a horizontal tray, degreasing, washing, chroming, air drying, flat spraying, drying and picking up. The powder coating is performed on the ceiling placed on a horizontal tray to prevent the powder from accumulating to one side due to its own weight, ensuring the uniform thickness of the powder layer. After drying and curing, the surface of the ceiling is also smoother and more beautiful, improving the overall quality; at the same time, due to the use of horizontal powder spraying, the metal ceiling is easy to realize mechanical operation between each step, reducing manpower and material resources, and also greatly improving production efficiency.

Advantages Of Square Ceiling Panel Production Line

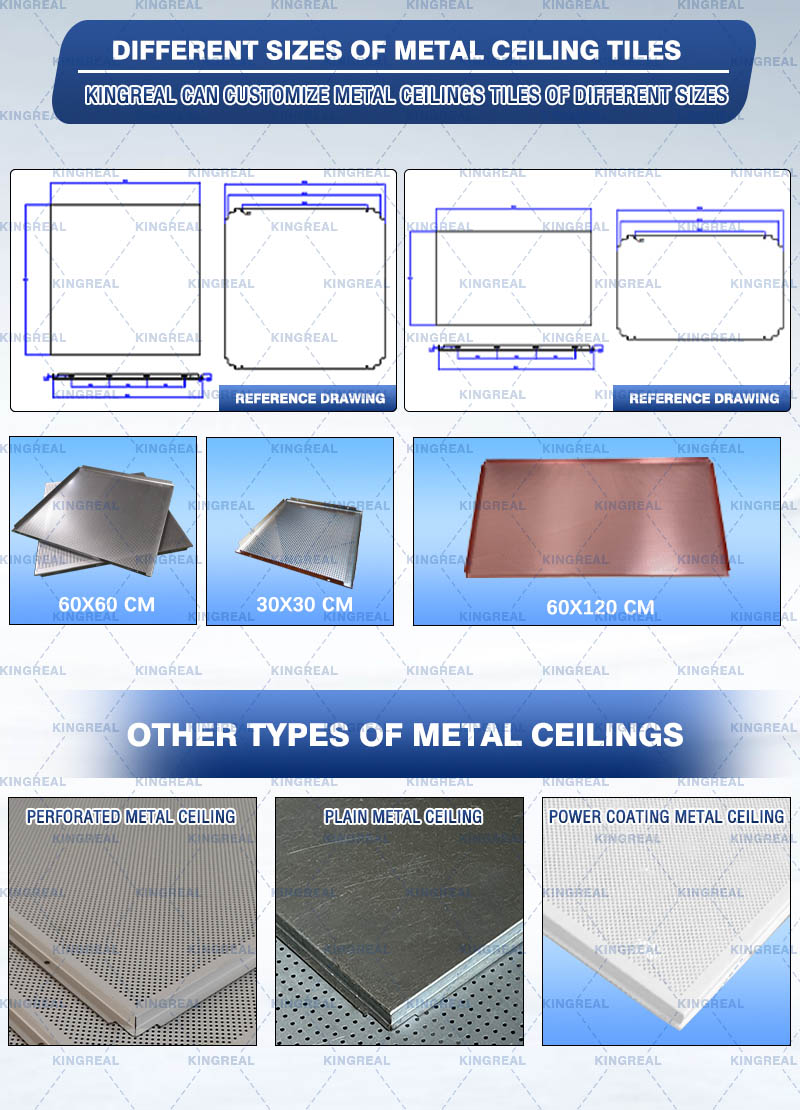

Different sizes of ceilings can be produced

The metal ceiling tile notching mold is designed as integral design and it can produce 30*30CM metal ceiling tile, 60*60CM metal ceiling tile and 120*60CM ceiling board on the same mold. KINGREAL CEILING MACHINERY metal false ceiling machine is featured with easy to operate, high speed output and full automatically running.

Fully automated design to reduce production costs

KINGREAL CEILING MACHINERY hydraulic ceiling tile bending forming machine can do the ceiling plates bending forming full automatically, the perforated sheet can be sent to the hydraulic bending forming press automatically by the manipulator. KINGREAL CEILING MACHINERY full automatic aluminum ceiling production line design can reduce machine and labor costs and the risk of work-related injuries, and can also save space, which has become a market trend.

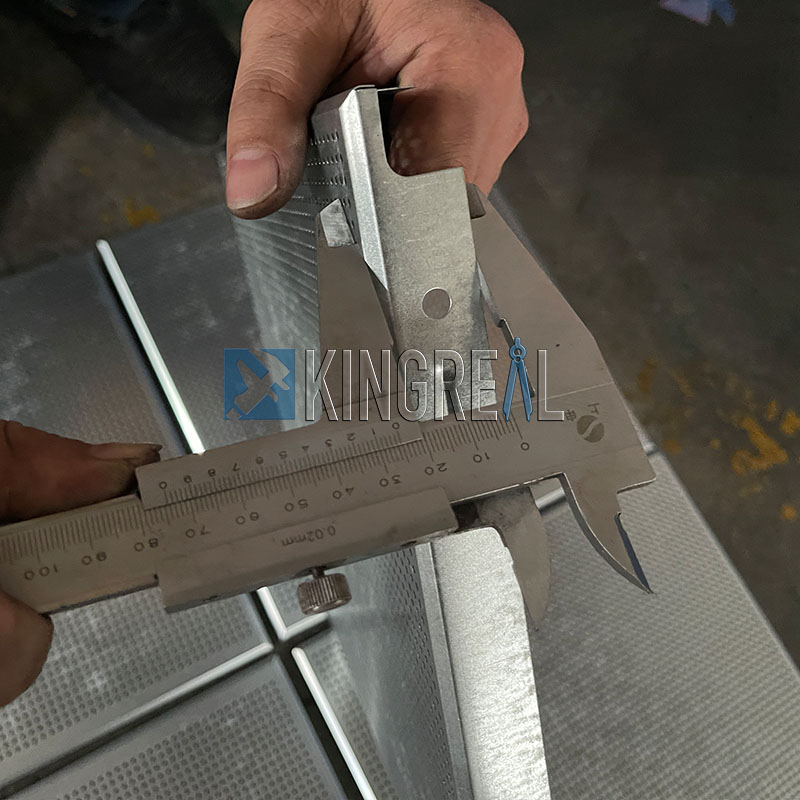

Unique hydraulic design

The hydraulic press will do the bending forming, after the ceiling tile bending forming, it will be pushed out. At the same time, one new perforated sheet will be put into the hydraulic press. KINGREAL CEILING MACHINERY hydraulic ceiling tile bending forming machine is 140ton high capacity hydraulic press.

Description Of Metal Ceiling Production Line

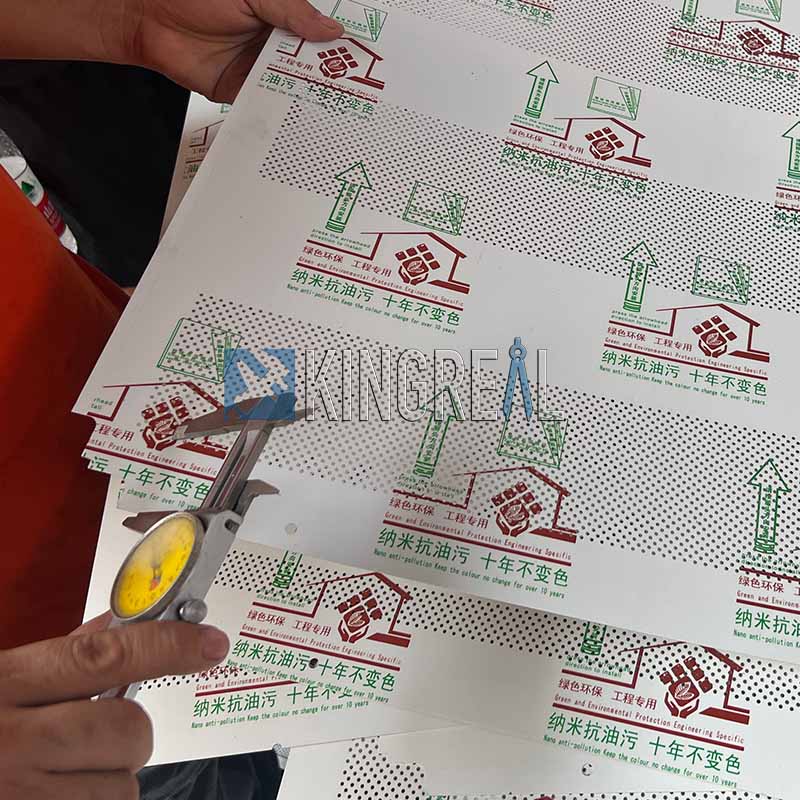

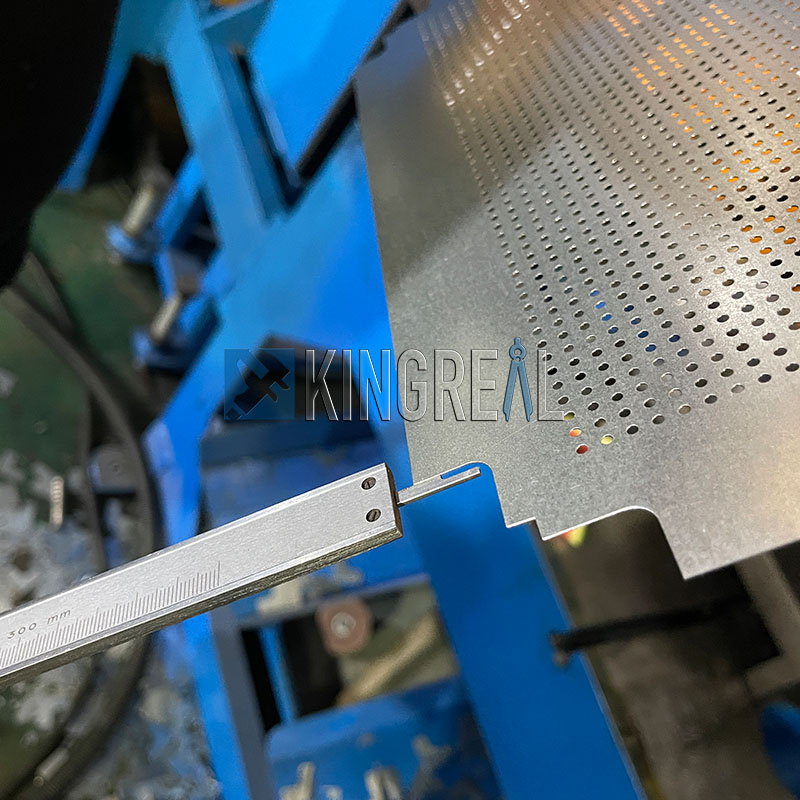

KINGREAL CEILING MACHINERY aluminum ceiling panel making machine uses high quality slow wire cut molds and it can do the ceiling boards perforation in high speed up to 250SPM. With KINGREAL CEILING MACHINERY technology, the ceiling tile surface is flat, the splicing is neat, the thick and thin materials can be adjusted, the equipment process is simple, and the operation is easy.

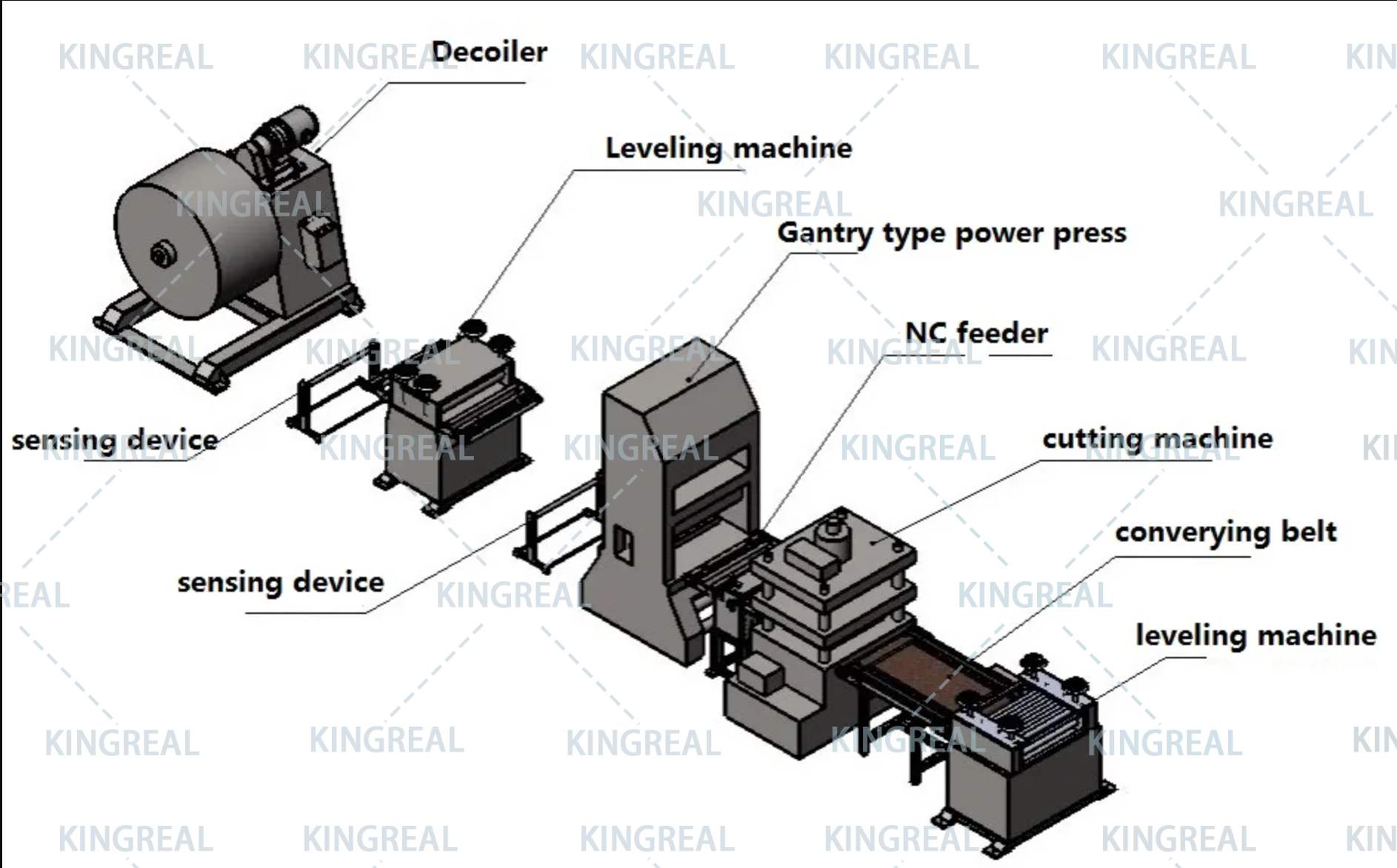

Composition Of Aluminum Ceiling Production Line

| Machine | Features | Amount |

| Decoiler | Hydraulic expansion | 1 Unit |

| Pre-straightener | High-precision 19 Rollers | 1 Unit |

| 125 Tons high-speed perforation press | 125Tons, 100-150 SPM, 2-5PCS tiles/min | 1 Unit |

| NC servo feeding machine | Yaskawa Servo motor, 3.0KW High accuracy | 1 Unit |

| Hydraulic notching & shearing press | 60tons Hydraulic press, High accuracy | 1 Unit |

| Transmission conveyor | Automatic | 2 Units |

| Precision straightener | High-precision 21 Rollers | 1 Unit |

| Automatic tiles flipping machine | For flipping 600*600 tiles 180 degrees | 1 Unit |

| Automatic feeding mechanical arm | For feeding 600*600 tiles to next step production | 1 Unit |

| Hydraulic bending forming press | For bending forming 600*600 tiles | 1 Unit |

| Electric control system | Reliable parts | 1 Unit |

Working Process of False Ceiling Machine

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press -- 2nd Precision Straightener -- Flipping machine -- Automatic tiles feeding machine -- Auto Bending Forming Machine

Full Auto & Semi Auto Metal Ceiling Panel Making Machine

KINGREAL CEILING MACHINERY provides customers with two metal ceiling production line solutions - fully automated and semi-automated metal ceiling production lines. Semi-automated metal ceiling production lines are suitable for start-ups with small production scales. Fully automated metal ceiling production lines are suitable for customers with large production scales and high requirements for production efficiency, which can free up manpower and improve production.

Product Display

KINGREAL CEILING MACHINERY often receives positive feedback from customers about the metal ceiling machine. Customers generally say that the finished products manufactured using KINGREAL CEILING MACHINERY's metal ceiling production line are excellent in precision and consistency, fully meeting the standards promised by KINGREAL CEILING MACHINERY in its manufacturing solutions. This high-precision production capability allows each ceiling to maintain consistent quality, ensuring a perfect fit in the application.

Diverse Metal Ceiling Tiles Solutions

KINGREAL CEILING MACHINERY's metal ceiling production line can produce metal ceilings of different sizes, including 300x300mm, 600x600mm, 600x1200mm, etc. And KINGREAL CEILING MACHINERY's fully automatic metal ceiling production line can also produce different types of ceilings, such as lay in, clip in, tegular, perforated ceilings and so on.

Customer Visit

KINGREAL CEILING MACHINERY warmly welcomes customers from all over the world to visit KINGREAL CEILING MACHINERY factory in China. Please do not hesitate to contact us immediately if you need any assistance.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)