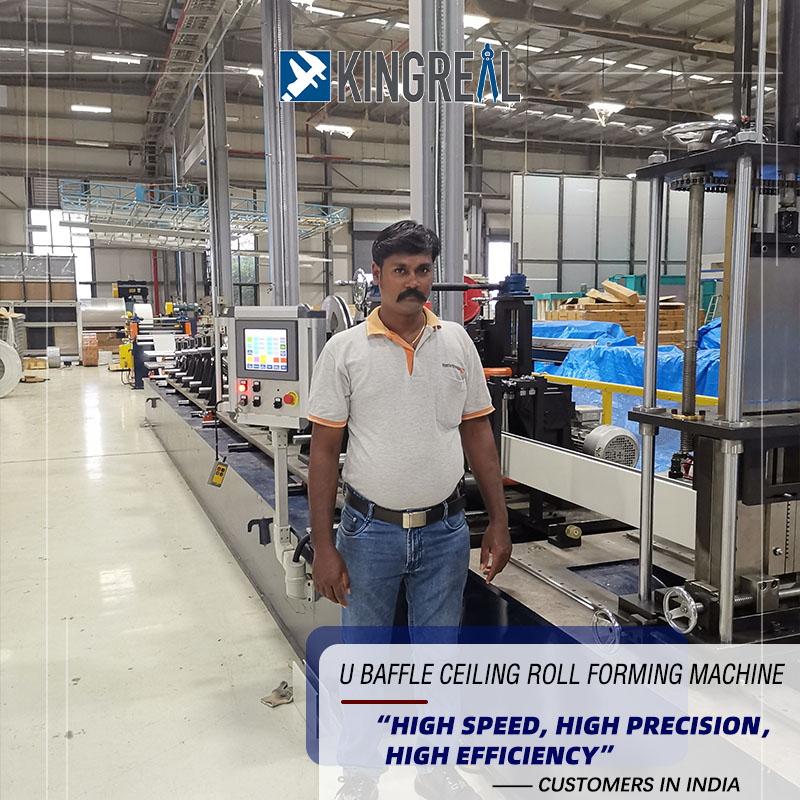

Customer Feedback -- Baffle Ceiling Production Line

2024-11-15 13:56

Today, KINGREAL CEILING MACHINERY received feedback from customers on baffle ceiling machine. KINGREAL CEILING MACHINERY baffle ceiling production line has been shipped to the customer's factory in India for a month, and after using it for some time, he spoke highly of KINGREAL CEILING MACHINERY u baffle machine. Here's his feedback:

"Thanks to KINGREAL CEILING MACHINERY, your baffle ceiling roll forming machine is so easy to operate. Soon after your technicians guide our factory employees, our employees can operate independently. This greatly accelerated the production speed of our factory, after a period of use, I made sure that every batch of it produced is the same quality, are high precision and no burr quality finished products. I have recommended your brand to friends in need!"

Thanks for Indian customer's recognition of KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY is a suspended ceiling roll forming machine manufacturer with more than 20 years of rich experience. We uphold the concept of continuous learning and continuous progress. We have been innovating for customers to make better and more efficient use of u baffle machines.

In order to better meet the production needs of customers, KINGREAL CEILING MACHINERY has launched 150mm height u baffle machine, 200mm height u baffle machine and 300mm height u baffle machine. Among them, 300mm height baffle ceiling machines are customized for our customer Douglas according to his special production needs.

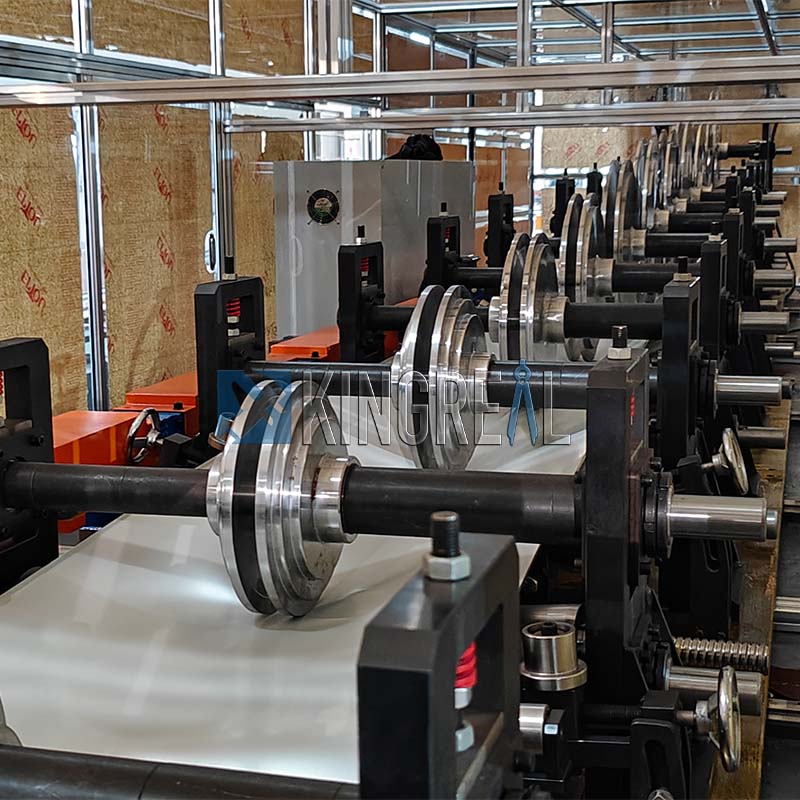

In order to minimize wear and prolong the service life of the baffle ceiling machine, KINGREAL CEILING MACHINERY has introduced a baffle ceiling production line with a protective shield. The function of the protective shield is to prevent dust, debris and other external substances from entering the inside of the machine, thereby reducing equipment wear and extending service life. At the same time, it also effectively prevents the operator from coming into contact with the moving parts, reducing the risk of accidental injury.

Advantage of Baffle Ceiling Machine Part

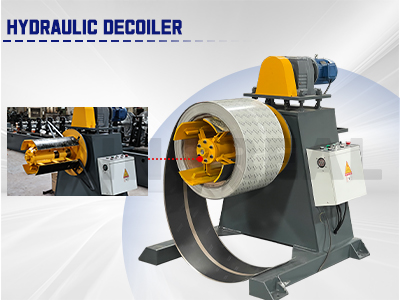

Hydraulic Decoiler

KINGREAL CEILING MACHINERY baffle ceiling production line is equipped with hydraulic decoiler. The hydraulic expansion method replaces the standard hand expansion method, which greatly reduces the labor intensity, saves the feeding time, and ensures the stability and safety of the feeding to a large extent.

Precision Strengthener

KINGREAL CEILING MACHINERY baffle ceiling machine of precision straightener's upper rollers has 10, the lower rollers has 11, a total of 21 rollers. More rollers provide more uniform pressure and support, helping to straighten the material more effectively and reduce warping and deformation, thereby increasing the accuracy of the product.

Touch Screen

The baffle ceiling production line of KINGREAL CEILING MACHINERY is equipped with intelligent touch screen, which supports multiple languages to facilitate the actual operation of customers in various countries. When it is necessary to produce baffle ceilings of different sizes, it is easy to adjust the height parameters of the roller set on the screen.

Cutting Station

The cutting system of the KINGREAL CEILING MACHINERY baffle ceiling machine adopts the follow shearing. You only need to enter the required cutting parameters. The system can detect the length of the baffle material through the sensor and control the tool to cut at the right time. Compared with stop cutting, the advantages of cutting with higher cutting efficiency and accuracy, because it can be adjusted while the material is running, reducing downtime and waste, which can greatly improve your productivity.

Get the latest price? We'll respond as soon as possible(within 12 hours)