What are the latest innovations in grilyato ceiling machines?

2025-03-07 17:00

Introduction of the grilyato ceiling machine

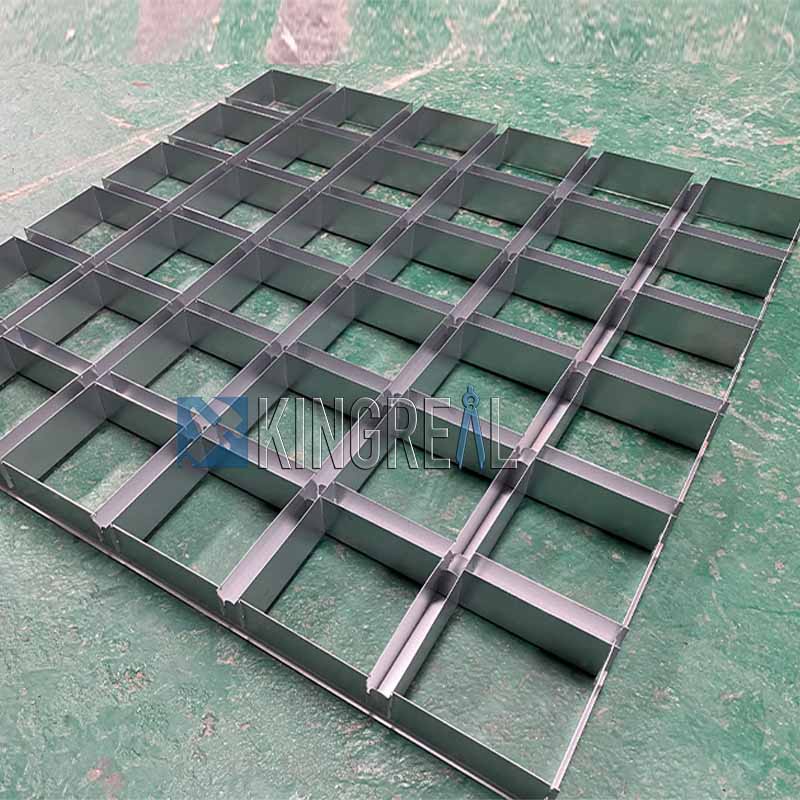

The grilyato ceiling roll forming machine is a device specially used to make grilyato ceilings. It puts metal coils into the grilyato ceiling production line, and finally makes a grilyato ceiling with a grilyato design through multiple links such as unwinding, leveling, punching, cutting and forming. Due to its unique structure and function, grilyato ceilings are widely used in modern architectural decoration.

The main uses of grilyato ceilings include:

✦ Indoor ceiling decoration: Provide beautiful ceiling solutions for large public places and commercial spaces.

✦Ventilation and heat dissipation: The grilyato design allows air circulation, which helps to improve indoor air quality.

✦Acoustic performance: The grilyato ceiling can effectively reduce noise and create a more comfortable environment for the space.

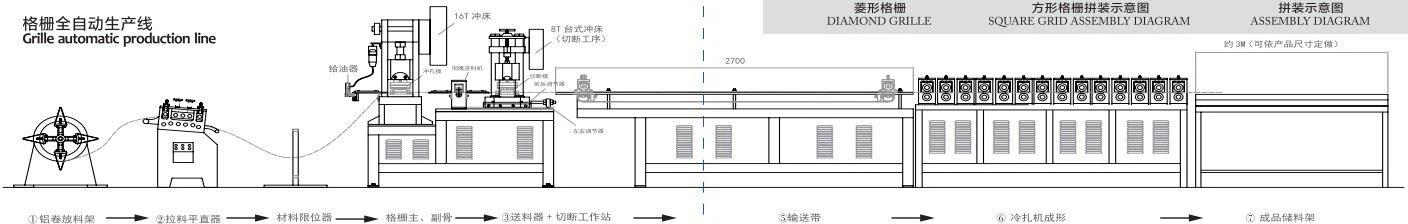

Workflow of grilyato ceiling production line

The workflow of the grilyato ceiling roll forming machine is divided into the following main steps:

1. Unwinding: Place the metal coil on the decoiler and adjust the tension to ensure that the metal material is smoothly unfolded.

2. Leveling: The metal coil may have waves or deformation after unwinding, and the leveling machine will correct it to ensure the accuracy of subsequent processing.

3. Punching: Use a punching machine to punch the flattened metal sheet to form the required holes.

4. Cutting: According to the design requirements, the cutting station will cut the perforated metal sheet according to the specific parameters required by the customer to ensure the accuracy of the size.

5. Forming: The metal sheet after punching and cutting will pass through the roll forming machine to make the final grilyato ceiling.

This series of processing steps ensures the high quality and precision of the grilyato ceiling, which has gained a good reputation in the market.

Application areas of grilyato ceilings

Grilyato ceilings are widely used in various indoor ceiling decoration places due to their grilyato design. The following are some of the main application areas:

1. Shopping malls and shopping centers

In large shopping malls and shopping centers, grid ceilings can not only provide beautiful visual effects, but also meet the needs of ventilation and heat dissipation, and enhance customers' shopping experience.

2. Leisure clubs and bars

Leisure clubs and bars usually pursue a unique atmosphere. The three-dimensional sense and open design of the grilyato ceiling can create a stylish and comfortable environment to attract more customers.

3. Airports and stations

In large public transportation hubs such as airports and stations, grilyato ceilings can provide good ventilation and acoustic performance, improve passengers' waiting experience, and also enhance the overall sense of space.

4. Office buildings and commercial office spaces

Grilyato ceilings are widely used in office buildings and office spaces. They can effectively separate spaces, provide good lighting and ventilation, and improve the comfort of the office environment.

Grilyato ceilings have become an indispensable part of modern architectural decoration due to their diverse application scenarios.

Market demand for grilyato ceiling production line

With the continuous improvement of people's requirements for the aesthetics of buildings, the market demand for grilyato ceilings is also increasing. The following are several key factors for the growth of market demand:

1. Three-dimensional sense and novel shape

Grilyato ceilings, with their unique grid design, provide a strong three-dimensional sense and modern sense, which can bring visual impact to the space and conform to the trend of modern architectural design.

2. Fire and moisture resistance

Grid ceilings usually use fire and moisture-proof materials, which can effectively reduce fire risks and improve the safety of buildings. At the same time, good moisture resistance enables them to maintain stability in humid environments.

3. Good ventilation

The open design enables the grilyato ceiling to have good ventilation performance, which can improve indoor air quality and ensure a comfortable living and working environment.

4. Simple and easy to install

The installation process of the grilyato ceiling is relatively simple, which can save time and labor costs and is favored by practitioners in the decoration industry.

Due to the above advantages, more and more decoration companies and consumers choose grilyato ceilings, which has driven the market demand for grilyato ceiling roll forming machines.

New innovation of grilyato ceiling production line

Faced with the growing market demand, KINGREAL CEILING MACHINERY continues to innovate the technology of grilyato ceiling roll forming machines, striving to help customers improve production efficiency. The following are KINGREAL CEILING MACHINERY's latest innovations in the field of grilyato ceiling machines:

* High-end grilyato ceiling production line:

KINGREAL CEILING MACHINERY has launched a high-end grilyato ceiling roll forming machine with higher production efficiency and forming quality.

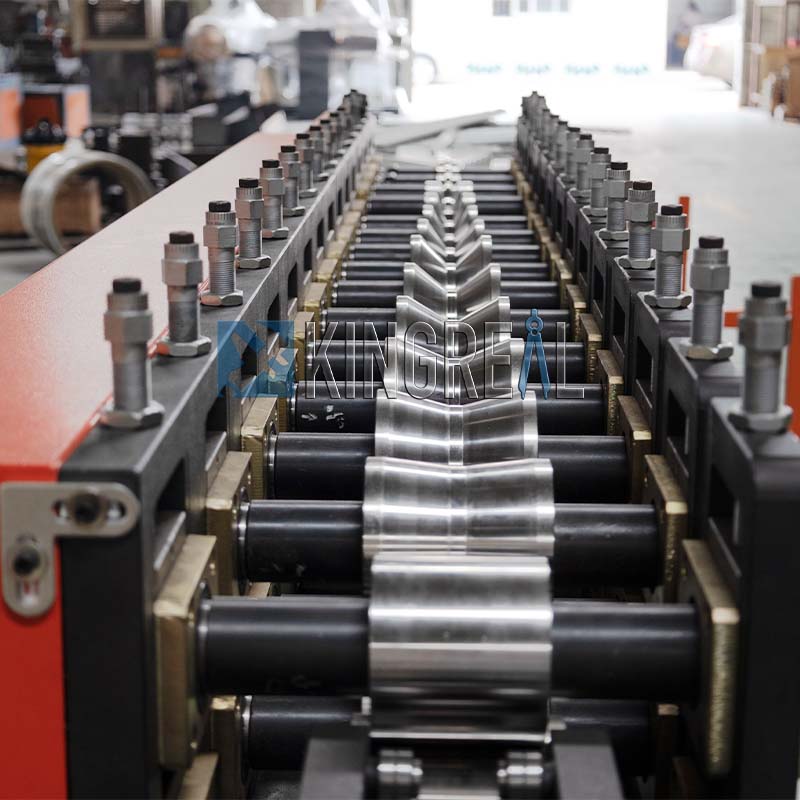

① Fast punching speed

The high-end grilyato ceiling production line uses a well-known brand of punching machine-Yangli. The punching speed of ordinary grilyato ceiling roll forming machines is usually 10-12 m/min, while the punching speed of high-end grilyato ceiling production lines can reach 30 m/min. This speed increase means a significant increase in production efficiency, which can meet the needs of mass production. In addition, the punch press of the high-end model can also punch one row at a time, further improving production efficiency.

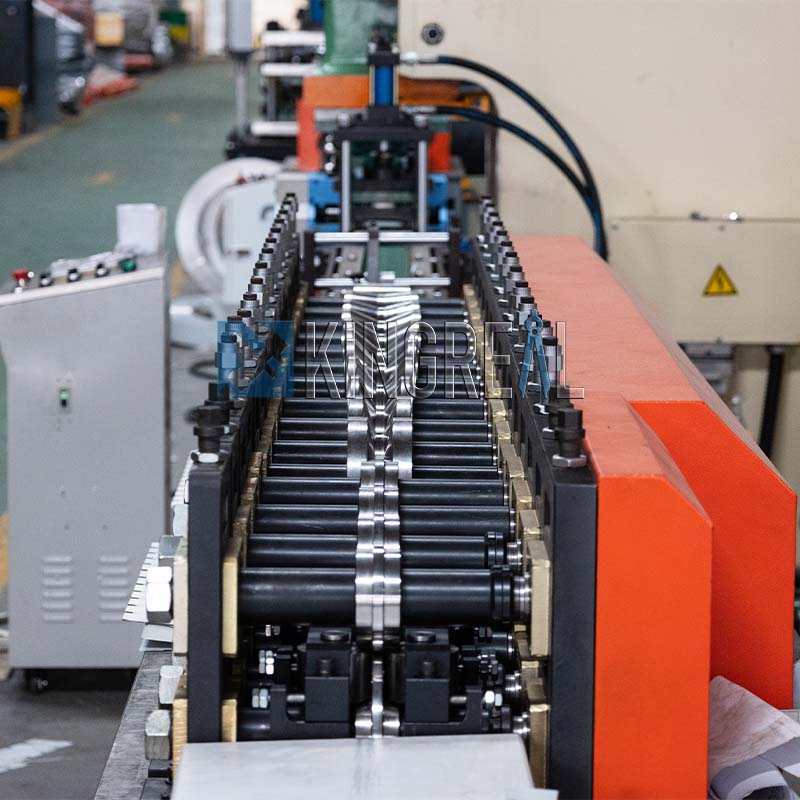

② Higher quality roll forming machine

KINGREAL CEILING MACHINERY has equipped the high-end grilyato ceiling roll forming machine with an independent archway. This innovative design significantly enhances the durability and operating stability of the equipment. The structural optimization of the independent archway enables the machine body to maintain good performance under high-intensity work, reducing the risk of failure due to mechanical fatigue.

In addition, this improvement also effectively improves the overall performance of the machine and ensures efficient coordination of all links in the production process. By reducing the failure rate, the grilyato ceiling production line can achieve longer continuous operation, thereby greatly improving production efficiency, meeting the needs of large-scale production, and creating greater economic value and competitive advantages for customers.

Through continuous technological innovation, KINGREAL CEILING MACHINERY's high-end grilyato ceiling roll forming machine has made significant progress in production efficiency, forming quality and intelligent control. These innovations not only meet market demand, but also provide customers with more competitive products.

In the future, with the continuous development of the construction industry, the market demand for grilyato ceiling production lines will continue to grow. KINGREAL CEILING MACHINERY will continue to be committed to technological innovation, provide customers with more efficient and higher-quality grilyato ceiling machine, and promote the progress and development of the entire industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)