Ceiling t bar machine maintenance guide

2025-02-07 11:31

Ceiling t bar machine is an efficient equipment used to produce t grids in the modern construction industry. With the continuous advancement of building materials and construction technology, the application of ceiling t grid machine has become more and more extensive, and it has become one of the indispensable equipment in the ceiling decoration process.

In order to ensure the efficient operation of the ceiling t bar machine and extend its service life, regular maintenance and care are essential. This article will start with the basic introduction of the ceiling t grid machine, elaborate on how to maintain it, and provide some practical tips.

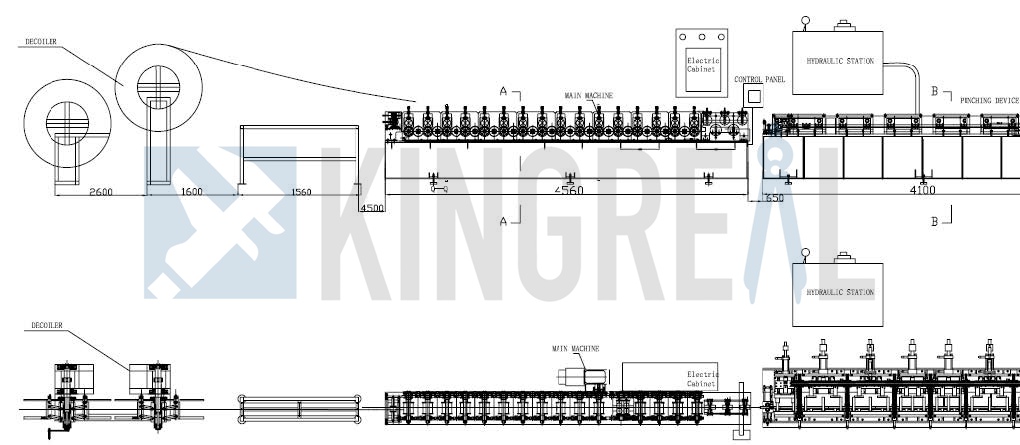

Workflow of ceiling t grid machine

unwinding - main roll forming - hydraulic punching and cutting - output

Maintenance of ceiling t bar machine

As an efficient production equipment, the daily maintenance of the ceiling t grid machine is directly related to the service life and production efficiency of the equipment. Therefore, regular maintenance is a necessary measure to ensure its normal operation and extend its service life. The following are several key points of ceiling t bar machine maintenance:

1. Regularly check the mechanical part

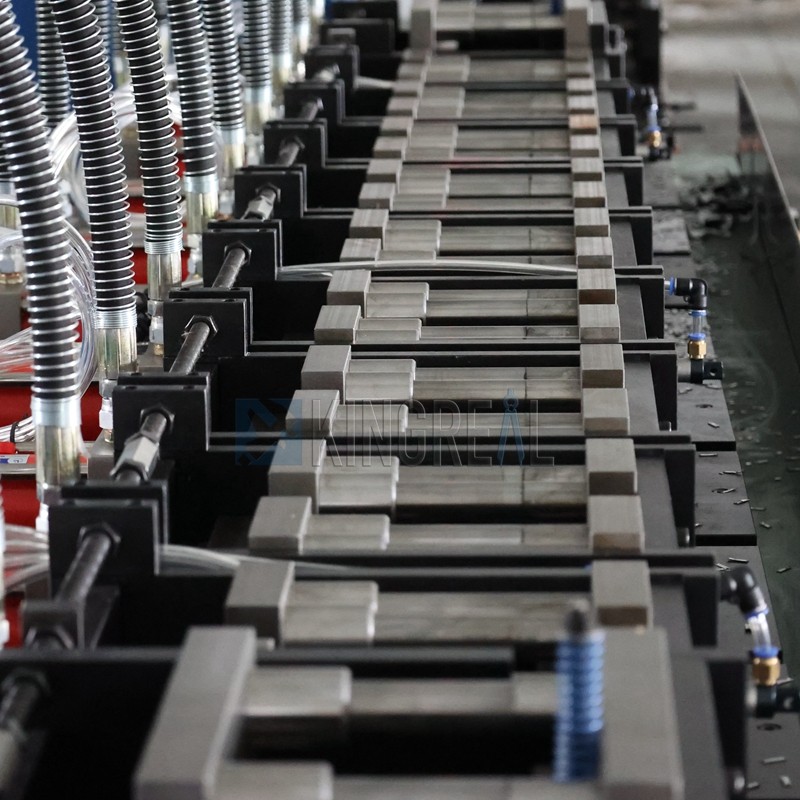

The mechanical part of the t grid roll forming machine includes the roll forming machine, cutting machine, punching machine, etc. It is very necessary to check these parts regularly. The main inspection contents include:

- Wear of rollers and molds: Rollers and molds are prone to wear during long-term use, affecting the molding effect, so it is necessary to regularly check whether there is excessive wear and replace them in time.

- Cutting machine tool: The sharpness of the cutting machine tool directly affects the cutting accuracy. Regularly check the wear of the tool and perform necessary grinding or replacement.

- Lubrication of the transmission system: The transmission system of the ceiling t bar machine is usually composed of gears, chains and other components. The transmission components need to be lubricated regularly to reduce wear and noise.

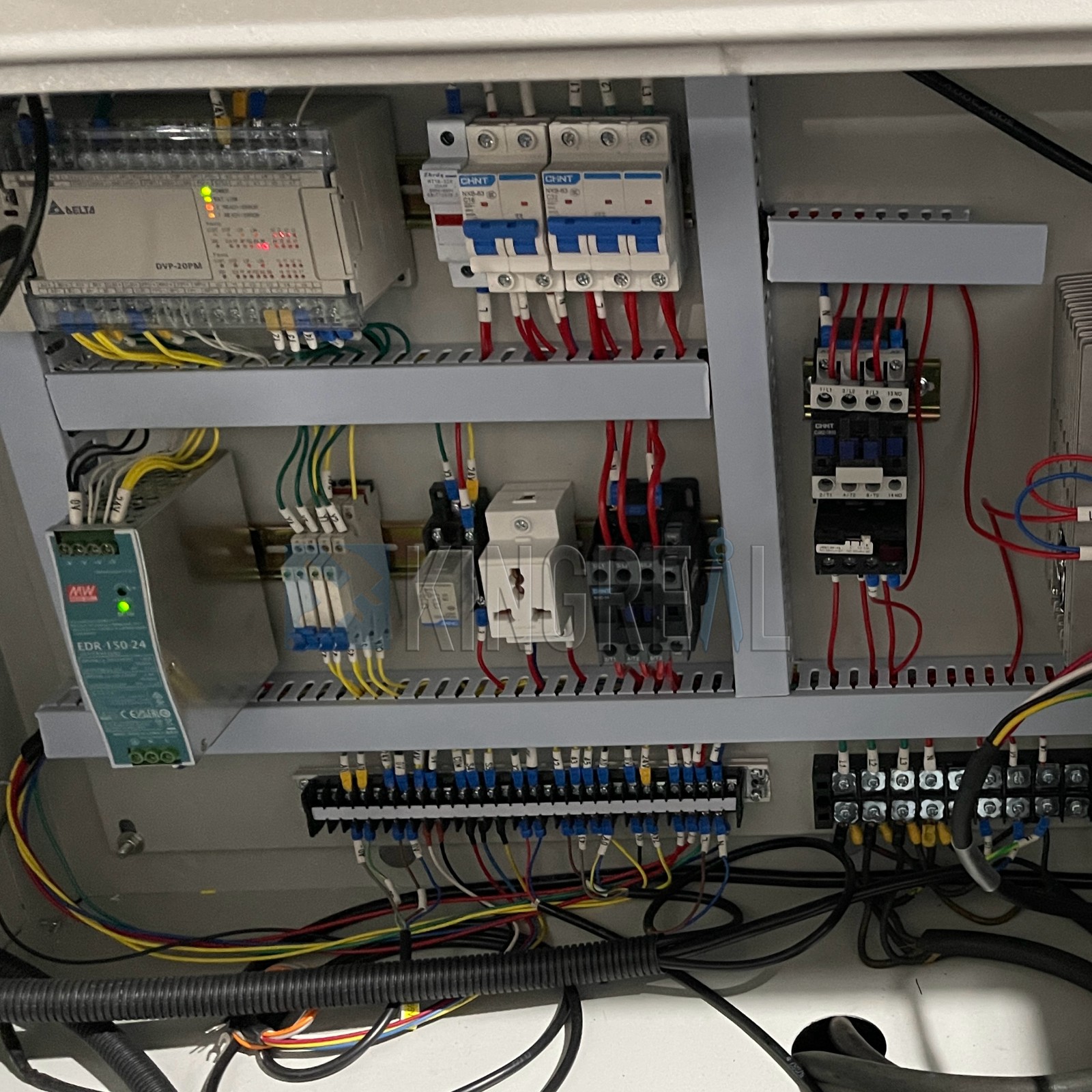

2. Inspection of the electrical system

The electrical control system of the ceiling t bar machine is crucial to the stable operation of the equipment. Regular inspection of the electrical system can effectively prevent the occurrence of electrical failures. The inspection contents mainly include:

- Cleaning and inspection of the electrical control cabinet: The interior of the electrical control cabinet should be kept clean to avoid dust accumulation affecting the normal operation of the equipment. Regularly check whether the lines and connectors in the electrical cabinet are loose or aging.

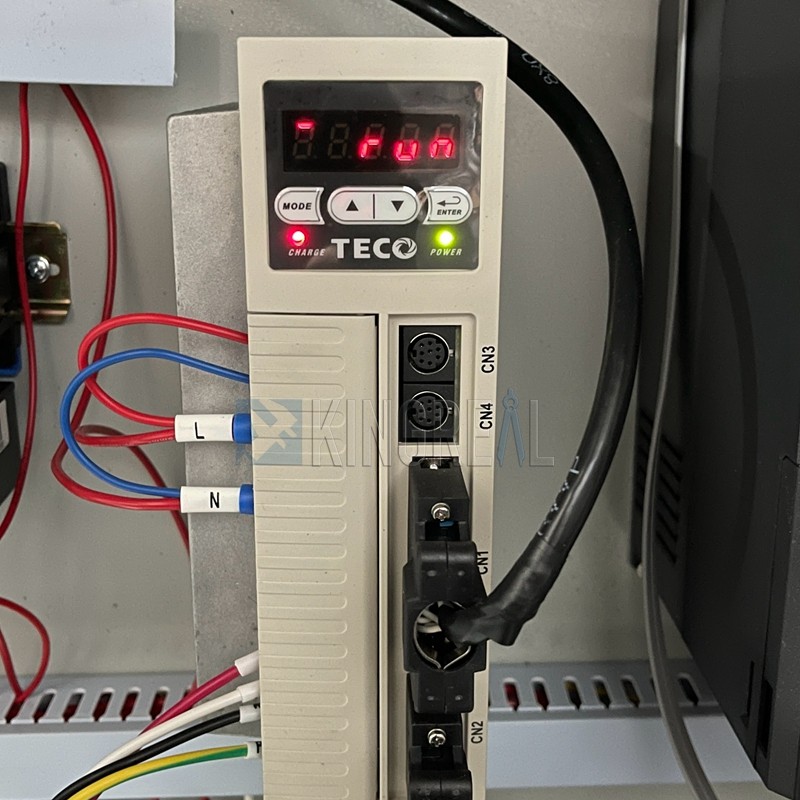

- Inspection of motor and inverter: Motor and inverter are the power source of ceiling t grid machine. Check their operating status regularly to avoid production stagnation due to electrical failure.

- Inspection of sensor and control panel: ceiling t bar machine is equipped with multiple sensors and control panels. Check the accuracy and sensitivity of these devices regularly to ensure that the equipment operates normally according to the predetermined parameters.

3. Cleaning and rust prevention

The oxidation reaction of metal materials in the air will cause rust, so it is particularly important to keep the t grid roll forming machine clean and rust prevention:

- Regularly clean the surface of the equipment: Use a soft cloth and non-corrosive detergent to wipe the surface of the equipment regularly to avoid oil and dust accumulation, which not only helps the appearance of the equipment to be neat, but also avoids equipment failure caused by dirt.

- Rust prevention: Especially in humid environments, t grid roll forming machines are more susceptible to corrosion. For metal surfaces, anti-rust oil should be applied regularly to prevent metal parts from getting damp and rusting.

4. Repair and replacement of parts

When some parts of the t bar roll forming machine are damaged due to excessive use, they should be repaired or replaced in time. Common parts that need to be replaced include:

- Roller and die of roll forming machine: These parts are prone to wear after long-term use, affecting the forming effect, so they need to be checked and replaced regularly.

- Cutting machine tool: If the tool is not replaced for a long time or is severely worn, it will lead to inaccurate cutting and even product scrapping.

- Punch and die of punching machine: The wear of punching parts will directly affect the quality and position of the hole and the subsequent assembly work, so they should be checked and replaced regularly.

Tips for ceiling t grid machine maintenance

When performing ceiling t grid machine maintenance, the following tips can help you improve the maintenance effect and ensure the long-term operation of the equipment:

1. Develop a regular maintenance plan: According to the frequency of use of the equipment and the working environment, develop a reasonable maintenance plan to ensure that each inspection and maintenance work is completed on time.

2. Use appropriate lubricants and cleaning agents: Choose lubricants and cleaning agents that match the equipment to avoid equipment damage due to improper use of products.

3. Spare parts inventory management: According to the common faulty parts of the equipment, do a good job of spare parts inventory management to ensure that they can be quickly replaced when there is a problem with the equipment to reduce downtime.

4. Operator training: Ensure that operators understand basic equipment maintenance knowledge, conduct regular training, and improve the standardization of operation and maintenance.

Some articles about

ceiling t grid machine

(2) How to use a t bar ceiling machine?

Get the latest price? We'll respond as soon as possible(within 12 hours)