Greek Customer Visited Factory -- Baffle Ceiling Carrier Machine

2024-11-21 16:40

Greek Customer Visited KINGREAL CEILING MACHINERY Factory

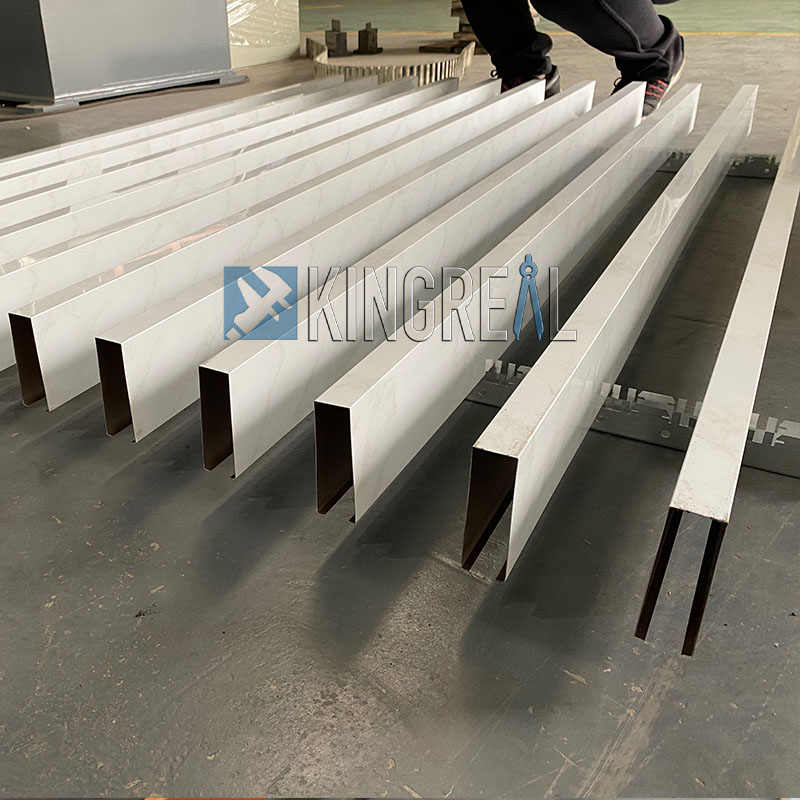

Nearly a month after KINGREAL CEILING MACHINERY's technical specialist spoke online to a Greek customer about the machine, A Greek customer who was interested in baffle ceiling carrier machines asked to visit the KINGREAL CEILING MACHINERY plant for a field trip. The main purpose of the visit was to check the operation of the machine and whether the quality of the finished product meets the requirements of the Greek customers.

The staff of KINGREAL CEILING MACHINERY warmly welcomed the arrival of the Greek customer and arranged a pick-up service for the customer, who was transferred to the factory of KINGREAL CEILING MACHINERY.

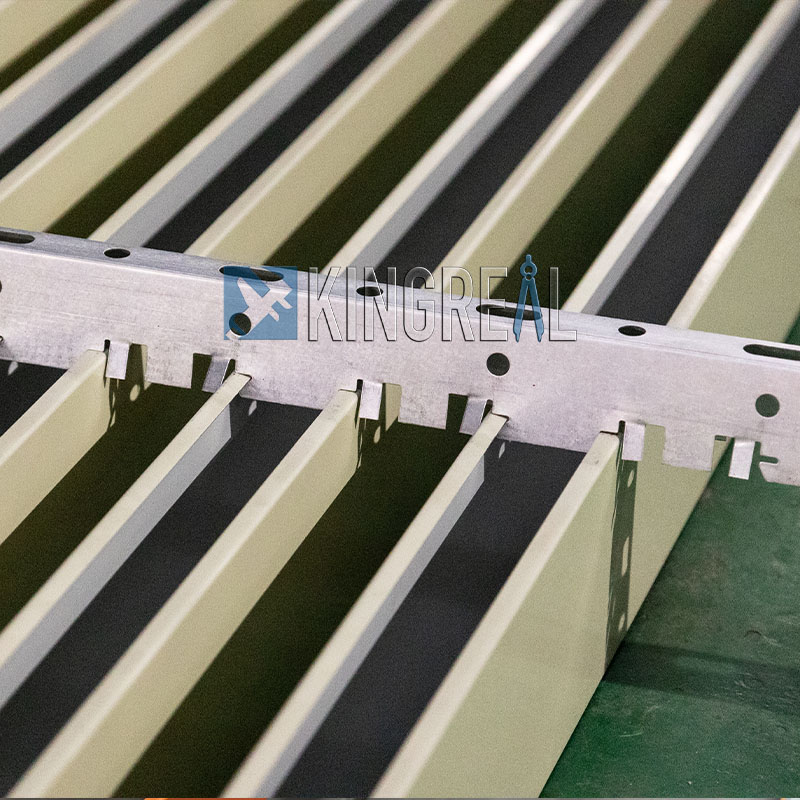

During the factory visit, KINGREAL CEILING MACHINERY staff introduced to customers that baffle ceiling carrier production line is composed of 2 in 1 decoiler and straightener, servo feeder, main roll forming machine, automatic cutting station and discharge table. In the process of visiting baffle ceiling carrier production line, the customer also raised many questions, such as baffle ceiling carrier machine maximum production speed can reach how much? The technicians of KINGREAL CEILING MACHINERY answered the customer's question: The maximum production line of baffle ceiling carrier machine can reach 10-15m/min. If you have special production needs, need faster production speed, welcome to communicate with engineers. The engineers of KINGREAL CEILING MACHINERY have rich experience in the metal ceiling making machine industry and can make customized solutions according to the actual production needs of customers.

The Greek customers are very much recognized by the equipment of KINGREAL CEILING MACHINERY, and have reached a preliminary cooperation intention with KINGREAL CEILING MACHINERY.

Features of Baffle Ceiling Carrier Production Line

KINGREAL CEILING MACHINERY automatic baffle ceiling carrier production line has the following main features:

① Full Automation. Automatic production line using self-developed automatic 2 in 1 decoiler and straightener, punching, forming, cutting, to achieve the automatic production of baffle ceiling carrier production line. The machine has the characteristics of easy operation, stable running, fast output speed, avoiding injury and so on.

② Reduce Costs and Reduce Safety Risks. Automatic baffle ceiling carrier machine is sensitive by mechanical control, without manual control accuracy. Reduce manpower, reduce costs for enterprises, but also reduce the safety risks caused by workers' work.

③ 2 in 1 decoiler and straightener. KINGREAL CEILING MACHINERY's baffle ceiling carrier machine is equipped with decoiler and straightener in one machine. The metal raw materials are fed into the head of the levelling machine by discharging and unwinding part of the rack of the two-in-one levelling machine, and then the internal stress is eliminated after rolling to achieve the levelling effect.

About KINGREAL CEILING MACHINERY

KINGREAL CEILING MACHINERY is one of our most distinctive products and one of the most purchased production lines from ceiling manufacturers. KINGREAL CEILING MACHINERY as a domestic professional metal ceiling production line manufacturer, from design - production - installation - after-sales, has more than 20 years of experience, according to the customer's drawings and specific parameters requirements, tailor-made production solutions.

Customer satisfaction is the biggest support for KINGREAL CEILING MACHINERY, KINGREAL CEILING MACHINERY will continue to work hard in the metal ceiling production line industry. If you have a need, please contact us.

Get the latest price? We'll respond as soon as possible(within 12 hours)