How are metal ceiling tiles manufactured?

2024-11-06 11:46

Any good product is not born easily, their production needs to go through a difficult process. In life, people often only see the finished products of many products, but do not know the production process behind them. So what is the production process of ceiling tiles? How are metal ceiling tiles made? Let's take a look together!

The metal ceiling is leveled by a metal ceiling production line of metal raw materials, punching and cutting angles, and other craft production. Main components of the line: Decoiler, Straightener, Perforation Press, Servo Feeder, Notching Press, Re-Straightener, Automatic Cleaning Machine, Automatic Turn-over Machine, Conveyor, Automatic Mechanical Arm, Bend Forming Press and Products Stacking System.

Next I will tell you in detail the whole process of the metal ceiling panel being made by the suspended ceiling machine.

Manufacturing process of metal ceiling

Step 1: Material slitting - Leveling

Material slitting: The raw material coil is longitudinally slit and transversely sliced to make ceiling tiles blanks;

Leveling: Each uneven ceiling tiles blanks is processed and leveled by a leveling machine, and then sent to the next process.

Step 2: Punching - Corner Cutting - Forming

Punching: Use perforation punching press to complete punching requirements. KINGREAL metal perforation punching press can punch different sizes and different pattern of holes as your need;

Angle cutting: Use Notching & Shearing Press Machine to complete corner cutting process. The size design of the cutting angle must be very accurate, and the angle cutting must be in place when cutting the angle. Otherwise, when the ceiling is hoisted, the intersection angles between the plates will be uneven;

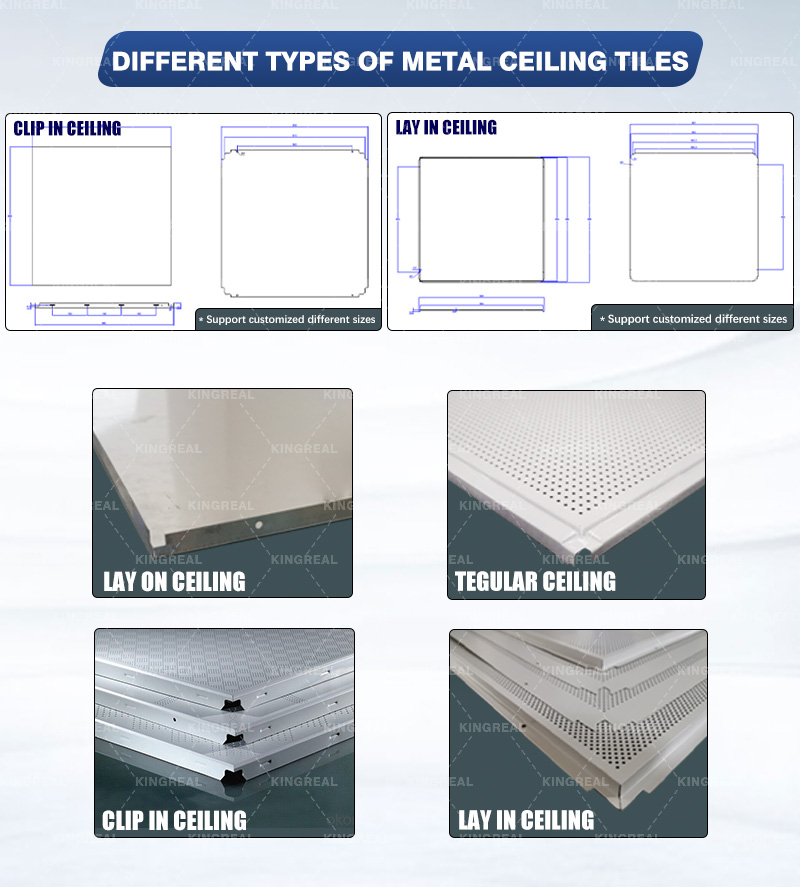

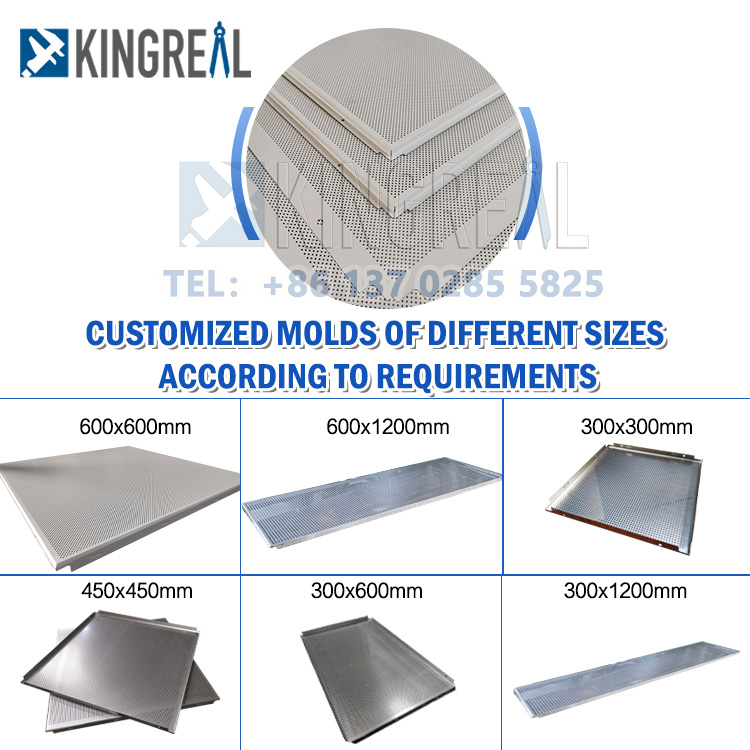

Bending forming: Send the ceiling boards to the hydraulic bending forming press and press it with a mold. By changing molds, you can bending forming lay in ceiling tile, clip in ceiling tiles or other types of ceiling tiles as your requirement.

Step 3: Fleece Sticking

Fleece sticking: In Kingreal CEILING MACHINERY full auto metal ceiling production line, the perforated ceiling tiles can be transported by auto feeder manipulator to the acoustic fleece gluing machine to complete sound-absorbing sticking. The entire process is completed automatically by the machine, which is convenient and fast and requires only minimal manpower.

Step 4. Inspection - Packaging

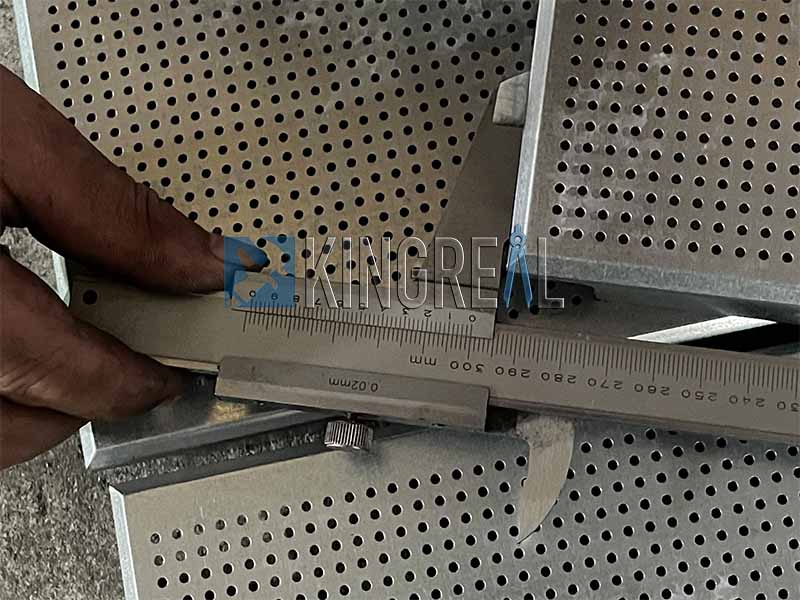

Inspection: Finished product inspection should check flatness and dimensional errors. This is a very important link. Quality inspection personnel can be specially arranged to conduct strict product inspection and completely eliminate unqualified products;

Packaging: Pack the fully qualified ceiling tiles without quality defects and put them into storage. At this point, the pieces of ceiling tiles are perfectly created.

Advantages of KINGREAL CEILING MACHINERY False Ceiling Machine

Production of Different Ceiling Types.

Capable of producing various types of ceilings. By changing different bending plate modules, the machine can form tiles into CLIP IN, LAY IN, or tegular styles. The mold change is very convenient, saving time and reducing the cost of purchasing additional machines.

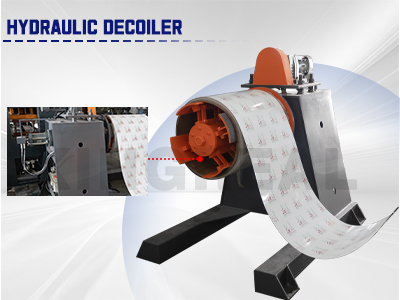

Hydraulic Decoiler.

The hydraulic expansion method replaces the standard hand expansion method, which greatly reduces the labor intensity, saves the feeding time, and ensures the stability and safety of the feeding to a large extent.

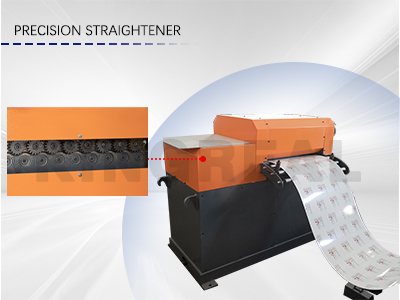

Precision Straightener.

The precision levelling machine of KINGREAL CEILING MACHINERY has 21 rollers, 10 on the upper wheel and 11 on the lower wheel.It can better level the metal sheet.

Product Display

Metal ceilings are widely used, basically indoor places will be installed on metal ceilings, you can see it in offices, hospitals, classrooms, restaurants and other places.

Get the latest price? We'll respond as soon as possible(within 12 hours)