How to Choose an Efficient Baffle Ceiling Machine?

2024-11-13 16:15

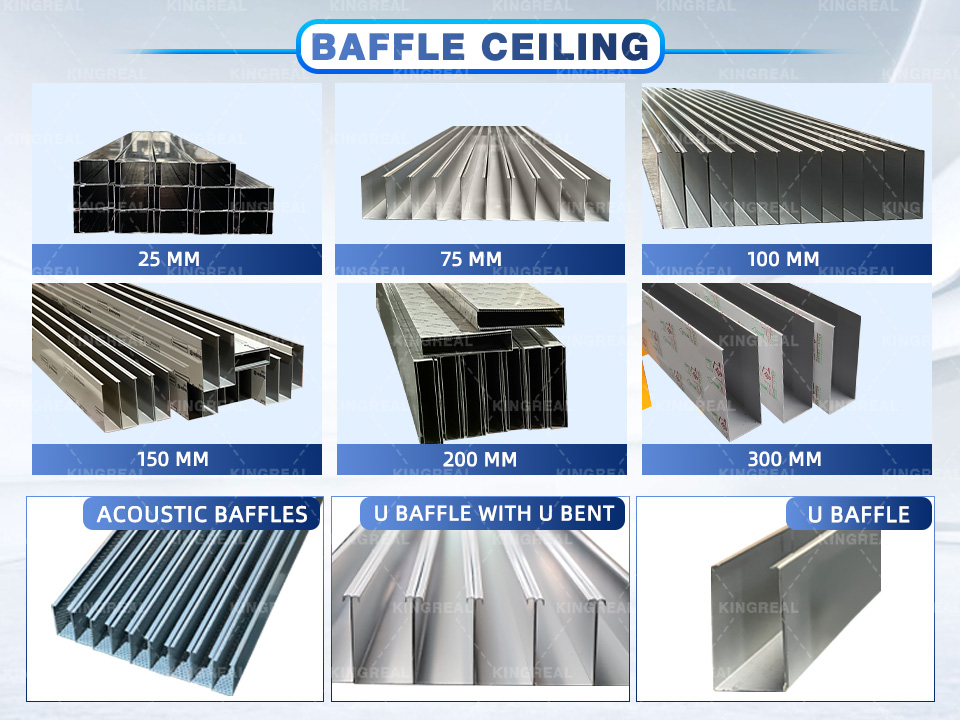

Baffle ceilings are essential for improving the aesthetics and acoustics of commercial spaces, office buildings, and industrial environments. A high-quality baffle ceiling roll forming machine is necessary for producing these suspended ceiling panels with precision. But how do you choose the best machine for your production needs?

What is a Baffle Ceiling Machine?

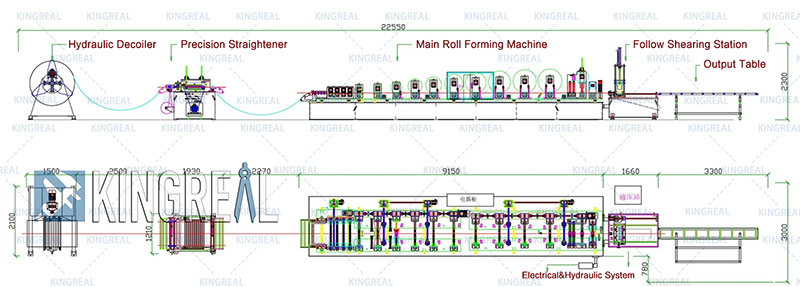

A baffle ceiling machine is a specialized equipment used to manufacture baffle ceiling panels from metal sheets. These machines perform various tasks such as uncoiling, straightening, forming, cutting. The machines are crucial for ensuring the U baffle ceiling design is executed correctly, meeting both visual and acoustic requirements.

Key Features to Consider

When selecting a baffle ceiling machine, several features are crucial in determining its efficiency and suitability for your business:

Machine Material Compatibility

One of the first things to evaluate is the material compatibility. Baffle ceiling machines can handle different metals, such as aluminum, steel, and stainless steel. Make sure the machine can accommodate the specific materials you plan to use in your projects KINGREAL CEILING MACHINERY baffle ceiling machine can handle Gi Steel, Aluminum, Pre-painted Gi Steel metal raw materials. If you have other needs, you are welcome to come to us, KINGREAL CEILING MACHINERY's engineers will definitely give you a complete solution.

Speed and Production Capacity

Speed is another essential consideration. U baffle machines vary in their output rates. Some machines can produce hundreds of panels per day, while others are slower. Determine how much volume you need to produce and choose a machine that meets those needs efficiently. KINGREAL CEILING MACHINERY u baffle machine speed can reach 30m/min. If you have more efficient special production needs, you are welcome to send us the drawings, the engineers of KINGREAL CEILING MACHINERY will be in full communication with you, for you to design a customized solution to meet your production needs.

Precision and Accuracy

Precision is critical when producing baffle ceiling panels. A machine with precise control over cutting and shaping will ensure that your panels fit seamlessly into the ceiling structure. KINGREAL CEILING MACHINERY baffle ceiling production line is equipped with precision straightener and cutting station, precision straightener has 10 wheels, 11 wheels, a total of 21 rollers. More rollers provide more uniform pressure and support, helping to straighten the material more effectively and reduce warping and deformation. The cutting system uses a following shearing, you only need to enter the required cutting parameters, the system can detect the length of the material through the sensor, and control the tool at the right time to cut. These two devices greatly improve the accuracy of the baffle ceiling.

Evaluate the Manufacturer's Reputation

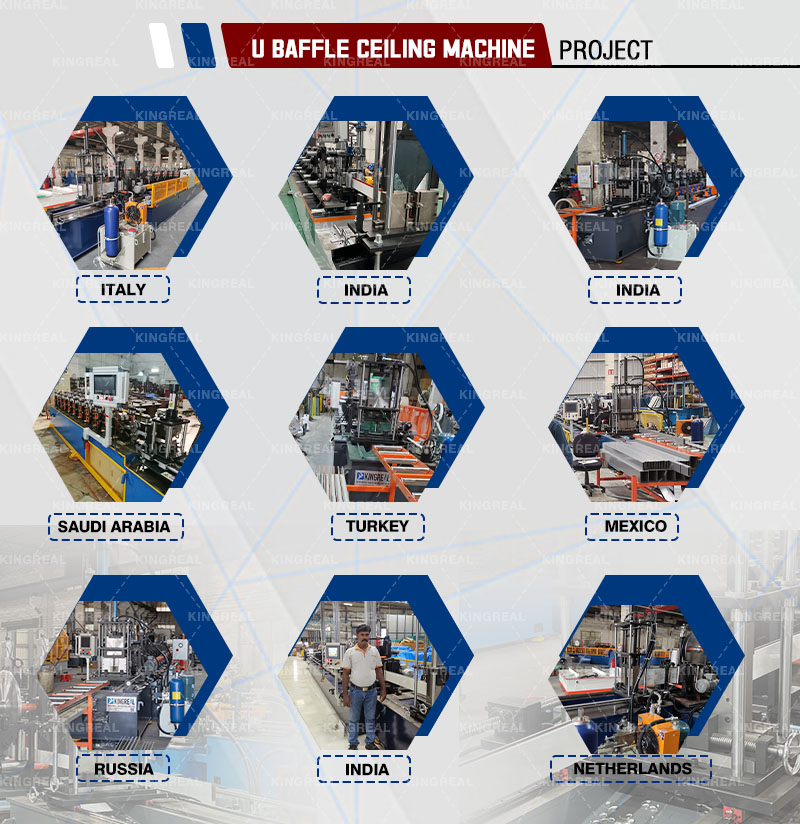

Choose a manufacturer with a proven track record in providing reliable and durable machinery. KINGREAL CEILING MACHINERY has more than 20 years of experience in the metal ceiling machine manufacturing industry, working closely with well-known brands such as Douglas. Products are exported to Japan, India, Mexico, Russia, the United Kingdom and other countries, KINGREAL CEILING MACHINERY can provide you with high quality partition baffle ceiling machines, and provide customized solutions according to your needs.

Budget Considerations

While advanced machines can offer high efficiency and precision, they may come with a higher initial cost. Balance your budget against the features and benefits to ensure you make a sound investment.

Why Choose a Baffle Ceiling Machine for Your Business?

Investing in a baffle ceiling production line brings several benefits, particularly if you are looking to expand your business or improve the quality of your products.

Improve Efficiency and Reduce Costs

A good baffle ceiling machine will streamline the production process, reducing the time and labor needed to manufacture ceiling panels. Over time, this can significantly reduce operating costs and improve your overall profit margins.

Enhance Product Quality

The precision of modern machines ensures that your baffle panels are uniform in size and shape. This consistency results in better-quality products, which is especially important in high-end commercial installations.

Customization and Flexibility

Modern baffle ceiling machines offer flexibility in terms of design. Customization features allow you to adjust the shape, size, and finish of the panels, making it easier to meet the specific demands of your clients.

Key Takeaways

Choosing the right baffle ceiling machine is crucial for improving production efficiency, product quality, and overall business performance. By carefully considering your material needs, production volume, machine speed, and maintenance requirements, you can select a machine that meets your specific needs. Whether you opt for a U baffle machine, a baffle ceiling roll forming machine, or a full production line, ensure that the machine you choose aligns with your business goals. KINGREAL CEILING MACHINERY offers over 20 years of expertise in providing customized baffle ceiling machines, making it a reliable partner for your production needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)