How to choose linear strip ceiling machine?

2024-12-11 11:58

Video About Linear Strip Ceiling Machine

Linear strip ceiling machine is a modern decorative material that can be used in commercial places that focus on modernization and decoration, such as shopping malls, supermarkets, etc. There are also subway stations and airports that can create a simple and atmospheric atmosphere. It is also loved by offices and can provide light and beautiful decoration solutions for office spaces.

Among them, the linear strip ceiling is made by putting the metal raw materials into the metal strip ceiling production line, and then going through multiple processes such as unwinding, leveling, forming, and cutting. The main components of the metal strip ceiling production line are decoiler, leveling machine, forming machine, cutting station, etc.

how to choose

linear strip ceiling machine?

It is a special equipment for producing decorative linear strip ceilings. Its quality and performance directly affect the product's forming accuracy, production efficiency, and the economic benefits of the enterprise. When purchasing a linear strip ceiling machine, you should not only pay attention to the price, but also consider it comprehensively from production needs, equipment quality, performance parameters, and after-sales service. The following is a detailed guide to purchasing metal strip ceiling production line to help companies make wise decisions.

① Production needs.

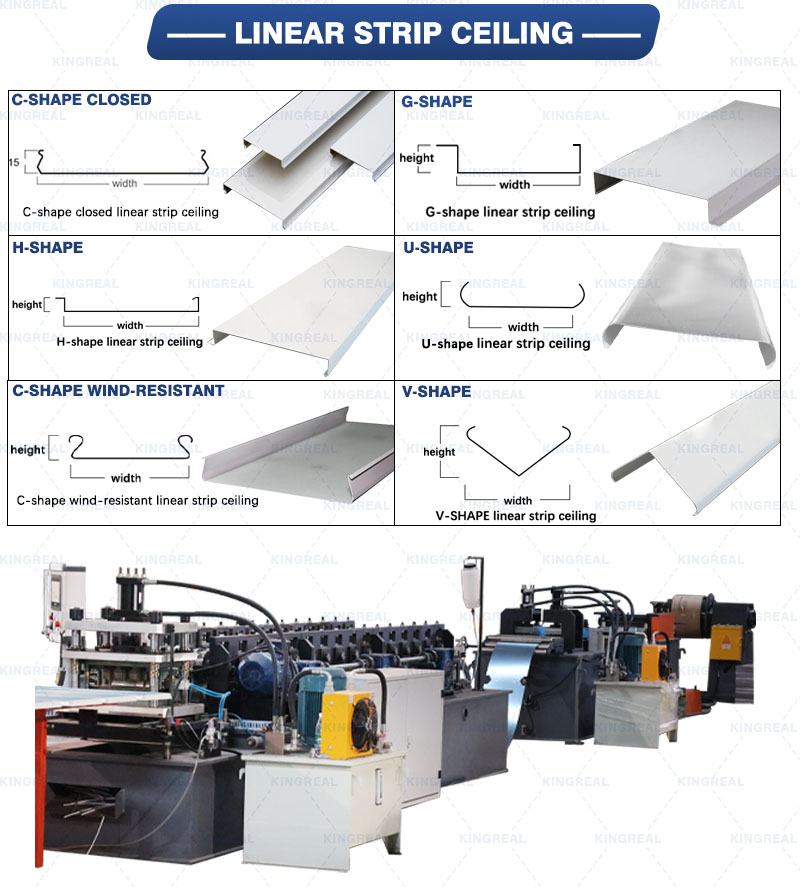

Before choosing a metal strip ceiling production line, the company should clarify its own product requirements, for example: Linear strip ceiling size range: The width (such as 50mm, 100mm, 150mm) and thickness (such as 0.3mm-1.0mm) of the linear strip directly affect the equipment selection. Whether there are requirements for material types (aluminum alloy, galvanized steel, stainless steel, etc.), different materials have different compatibility requirements for equipment. And whether it is necessary to produce strip ceilings of various shapes (such as U-shaped, C-shaped, V-shaped), it is more efficient to choose equipment that supports fast mold switching.

For production capacity requirements: whether high-speed production and molding are required, if long-term continuous production is required, high-durability equipment must be selected.

KINGREAL CEILING MACHINERY has three common linear strip ceiling machines that can be provided to customers-adjustable width and narrow machines, economical linear strip ceiling machines, and standard linear strip ceiling machines. Customers can choose KINGREAL CEILING MACHINERY's linear strip ceiling machine according to their own needs. Among them, the adjustable width and narrow linear strip ceiling machine is suitable for producing strip ceilings of different sizes; the standard linear strip ceiling machine can meet the production needs of high-precision strip ceilings; the economical strip ceiling machine requires the raw material to be thin metal sheets, which is suitable for customers with low requirements for production speed and precision.

② Price.

Price is the primary consideration when purchasing a linear strip ceiling machine. The price is divided into two aspects: initial purchase cost and long-term cost.

(1) Initial investment

Based on the budget range, examine the prices of different brands and models. Prices usually vary according to factors such as the degree of automation, production speed, and supported specifications. However, it should be noted that you should avoid choosing equipment that is too low in price but cannot guarantee quality.

(2) Long-term cost

Maintenance cost: High-quality equipment has a low maintenance frequency, but requires regular maintenance.

Energy consumption: Choosing energy-saving equipment can reduce production and operation costs.

Material utilization rate: High-precision equipment can reduce scrap rate, thereby saving material costs.

③ Quality.

The quality of the linear strip ceiling machine can be considered in the following three areas:

(1) Core component quality.

The core components are mainly forming rollers and electronic control systems. KINGREAL CEILING MACHINERY's linear strip ceiling machine is equipped with a forming roller mold made of high-strength wear-resistant steel, which can extend the service life of the machine and produce high-precision finished products. The electrical system is controlled by a high-quality PLC control system to improve production stability and reduce the failure rate.

(2) Equipment operation performance.

KINGREAL CEILING MACHINERY's linear strip ceiling machine has the characteristics of stability and simple operation. The machine runs smoothly and with low noise, avoiding vibration that affects the forming accuracy. The linear strip ceiling machine is equipped with a touch screen control device with a user-friendly interface, which is more convenient for workers to operate, and the fast mold replacement speed can significantly improve production efficiency.

(3) Machine automation.

KINGREAL CEILING MACHINERY's linear strip ceiling machine has a high degree of automation and has automatic feeding, cutting and stacking functions, which can save labor and improve efficiency. The equipment is also equipped with intelligent monitoring and fault alarm functions, which is helpful for monitoring and management.

④ After-sales service.

The after-sales of the linear strip ceiling machine also needs to be considered. As a senior manufacturer, KINGREAL CEILING MACHINERY has rich experience. First of all, KINGREAL CEILING MACHINERY has a good reputation. In the past 20 years of production experience, it has served more than 100 manufacturers and has a good reputation. And KINGREAL CEILING MACHINERY ensures that the equipment passes ISO9001 or other relevant certifications. KINGREAL CEILING MACHINERY can provide meticulous after-sales service and technical support to customers. KINGREAL CEILING MACHINERY engineers can install, debug and train customers on equipment. If spare parts need to be replaced, KINGREAL CEILING MACHINERY can also provide them in time without delaying customers' production.

Various types of linear strip ceiling machines

KINGREAL CEILING MACHINERY can provide different linear strip ceiling machines according to customers' different production needs. If you have special production needs, please come to consult KINGREAL CEILING MACHINERY!

Sum up

The metal strip ceiling production line is the core equipment for producing high-quality linear strip ceilings. Its selection needs to be comprehensively evaluated based on the company's production needs, budget, equipment performance, after-sales service and other factors. The various linear strip ceiling machines provided by KINGREAL CEILING MACHINERY can meet the needs of different customers and win the trust of customers with its high quality and perfect service.

Choosing a high-quality metal linear strip ceiling machine can not only improve the company's production efficiency, but also enhance its market competitiveness and lay a solid foundation for the long-term development of the company.

Get the latest price? We'll respond as soon as possible(within 12 hours)