How to use a t bar ceiling machine?

2024-11-14 15:47

Video About Ceiling T Bar Machine

The t bar ceiling machine is a highly practical tool used in building and renovation, primarily for ceiling installation as well as the splicing and connection of keels. When used properly, it can improve construction efficiency, reduce labor costs, lower the intensity of workers' efforts, and meet the demands of modern construction and decoration.

The KINGREAL CEILING MACHINERY fully automatic t bar ceiling roll forming machine adopts the most advanced domestic technology, consisting of three cold roll forming machines to produce main t bar grid, cross drop ceiling t bar and wall angle profile.

The KINGREAL CEILING MACHINERY automatic t bar ceiling roll forming machine can automatically form steel strips into various sizes and lengths of t bar ceilings according to customer requirements. If you have any questions, feel free to contact us! This article will provide a detailed introduction to t bar ceiling machines and t bar ceilings.

Working Process of T Bar Ceiling Machine

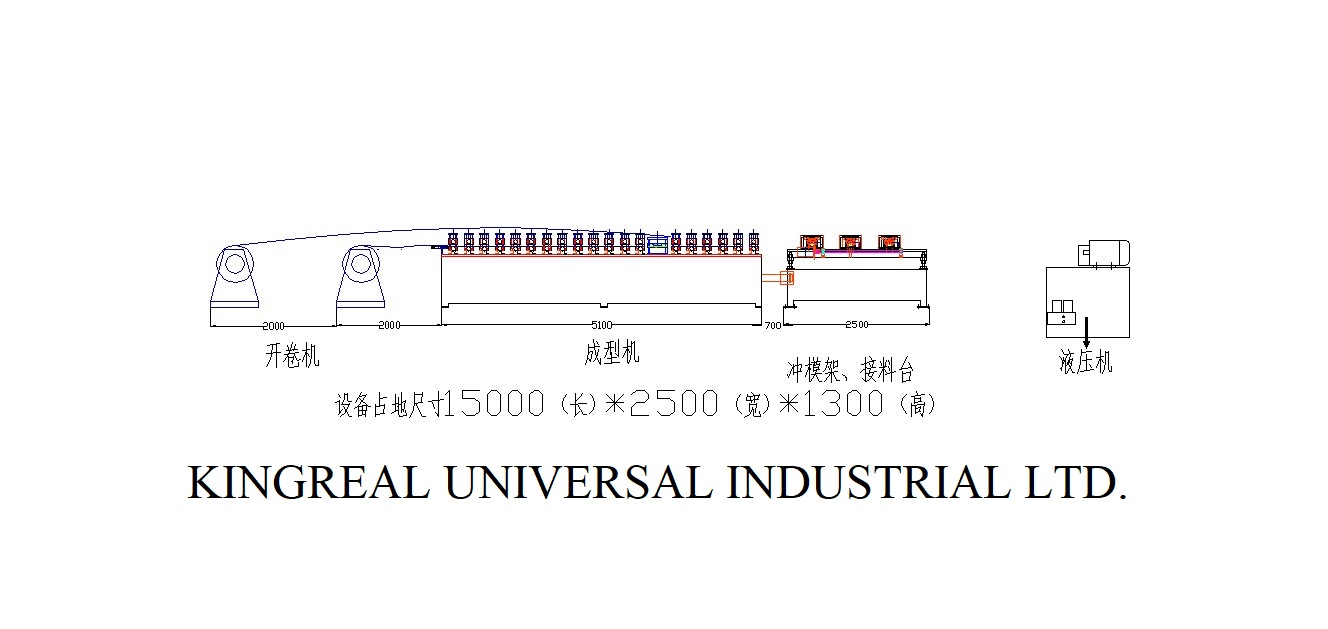

Hydraulic Decoiler -- Main Roll Forming Machine -- Punching and shearing station -- Product table

Assembling the T Bar Ceiling Roll Forming Machine

Before using the t bar ceiling machine, the machine needs to be assembled. Prior to assembly, the instruction manual should be read carefully, and all parts of the machine should be cleaned to ensure proper operation. After assembling the machine, all knobs and screws should be adjusted and tightened to ensure safety and stability.

Advantages of ceiling t bar machine

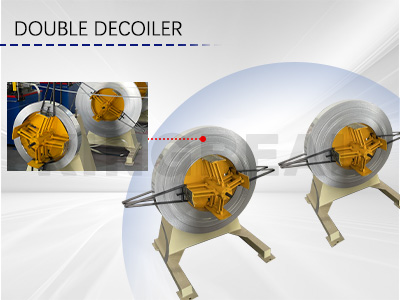

Double decoilers

The t bar ceiling roll forming machine adopts a double decoilers design and is equipped with two independent decoilers, which are used to feed paint and galvanized materials respectively. The advantages of this design are:

Improve production efficiency: The two decoilers work at the same time, reducing the downtime of the traditional single decoiler when changing materials, thereby improving the overall production efficiency. The double decoilers technology ensures the continuous supply of paint and galvanized materials, making the production process smoother.

Simplify the operation process: The operator can monitor the operation status of the two decoilers at the same time, reducing the complexity of equipment operation and improving work efficiency.

Reduce the waste of raw materials: Since the double decoilers can accurately control the feeding, the waste of raw materials caused by changing or uneven feeding is reduced, further reducing the production cost.

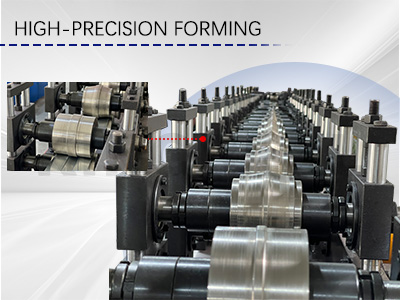

Precision forming

The ceiling t bar machine performs well in forming accuracy and operation stability, which is specifically reflected in the following aspects:

High speed and high precision: The running speed of the ceiling t bar machine can reach up to 30 m/min. At high speed, it can still maintain the accuracy of forming. This enables the equipment to effectively shorten the production cycle and increase output during mass production.

Smooth operation: The t bar ceiling roll forming machine ensures smooth operation at high speeds through advanced drive systems and precise mechanical design. This not only improves the molding quality of the product, but also reduces the wear and failure rate of the equipment, thereby reducing maintenance costs.

Strong adaptability: The ceiling t bar machine can be flexibly adjusted according to products of different specifications and requirements to ensure that diverse market needs are met.

Punching and shearing function

The punching and shearing function of the t bar ceiling roll forming machine is a highlight, which can accurately cut the ceiling t bar according to the customer's preset length. The specific advantages include:

Improve flexibility: Customers can set different cutting lengths according to actual needs, and the equipment can automatically adjust according to the set value. This flexibility makes production more personalized and can meet the specific requirements of customers.

Reduce manual intervention: The punching and shearing function can automate the cutting process, reduce dependence on manual operation, thereby reducing the risk of human error and improving production consistency.

Improve production efficiency: Through automated cutting, the equipment can respond quickly, improve production efficiency, ensure timely delivery, and better meet market demand.

Safety protection design

Safety is the top priority in factory production. The t bar ceiling roll forming machine fully considers the safety of workers and the protection of the factory environment in its design, which is mainly reflected in:

Protective shield design: The ceiling t bar machine is equipped with a safety protective shield to effectively prevent operators from being accidentally injured at work. The protective shield can effectively isolate the moving parts to prevent the operator's hands or other parts from accidentally contacting the moving mechanical parts.

Reduce environmental pollution: The design of the t bar ceiling roll forming machine also takes into account the protection of the factory environment, and is equipped with a dustproof device to reduce the dust and noise pollution generated during the production process, creating a safer and more comfortable working environment.

Improve work efficiency: The safety design not only protects the personal safety of workers, but also improves the work enthusiasm of employees. When workers feel safe and secure, they can focus more on their work, thereby improving overall production efficiency.

Installing the T Bar Ceilings

Before installing the t bar ceiling, proper construction preparations should be made, including aligning the ceiling and walls. Next, the main beam of the keel should be installed manually. In places where fixing is needed, place the keel in the designated position, and lightly press down the machine’s operating lever to fix the keel in place. Then install the secondary beams in the same way. During installation, pay attention to the position and spacing of each keel.

Splicing the T Grid Ceilings

When splicing t bar ceilings, the specific length of each t grid ceiling should be determined according to the design drawings, and the t grid ceilings should be cut to size. Align the t bar ceilings that need to be spliced, and gently press down the operating lever of the t bar ceiling machine to complete the splicing. Ensure the alignment and positioning of the t bar ceilings to avoid misalignment or gaps.

Inspecting the Decoration

After installing the ceiling, inspect the installation of the keels. A professional keel inspection tool should be used, and the inspection should include checking the flatness, the correct positioning, and the sturdiness of the splicing. Any problematic areas should be corrected and adjusted promptly, ensuring that every keel is properly installed before the work is considered complete.

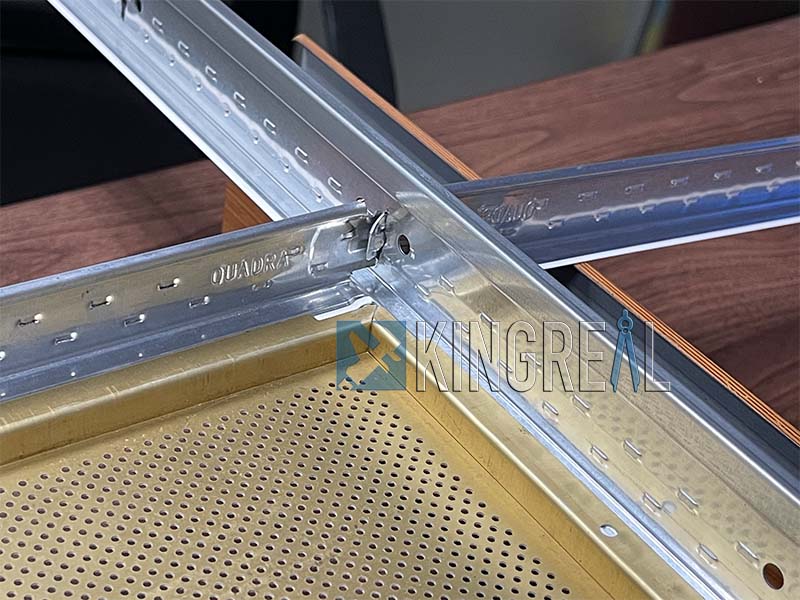

Characteristics of T Bar Ceilings

1. Good Stability: T grid ceilings adopt a “T” shaped cross-section design, providing stable support and fixation in the ceiling system.

2. Easy Installation: T bar ceilings are easy and convenient to install, allowing for the quick setup of ceiling systems.

3. Strong Corrosion Resistance: Aluminum t bar ceilings offer excellent corrosion resistance, making them suitable for ceiling systems in humid environments.

T Grid Ceilings Specifications

1. Steel T Bar Ceilings: Common specifications are 38*24*3600mm, 32*24*3600mm, 26*24*3600mm, etc.

2. Aluminum T Bar Ceilings: Common specifications are 38*24*3600mm, 32*24*3600mm, 26*24*3600mm, etc.

3. T Bar Ceilings Thickness: Generally ranges between 0.3–1.2mm.

4. T Bar Ceilings Length: Generally ranges between 3000–6000mm.

5. Cross-sectional Shape of T Bar Ceilings: The cross-sectional shape of t grid ceilings is "T" shaped, with the upper width generally being 24mm and the lower width generally being 38mm.

Get the latest price? We'll respond as soon as possible(within 12 hours)