What is Aluminum Baffle Ceiling?

2024-11-12 11:55

Video About U baffle machine

Aluminum baffle ceiling, also known as aluminum channel ceiling, has become one of the more common ceiling materials in recent years. Its transparency, strong decorative effect, and high fire resistance have made it increasingly popular for concealed projects and high-traffic public spaces. It is also an indispensable part of many home renovations.

Among them, the metal baffle ceiling is produced by the baffle ceiling roll forming machine to flatten, shape, and cut the metal raw materials. This article will provide a detailed introduction to more information related to aluminum baffle ceilings.

Definition of U Baffle Machine

An aluminum baffle ceiling is a ceiling made from aluminum baffle materials, which are also known as U-shaped baffles or U-shaped channels.

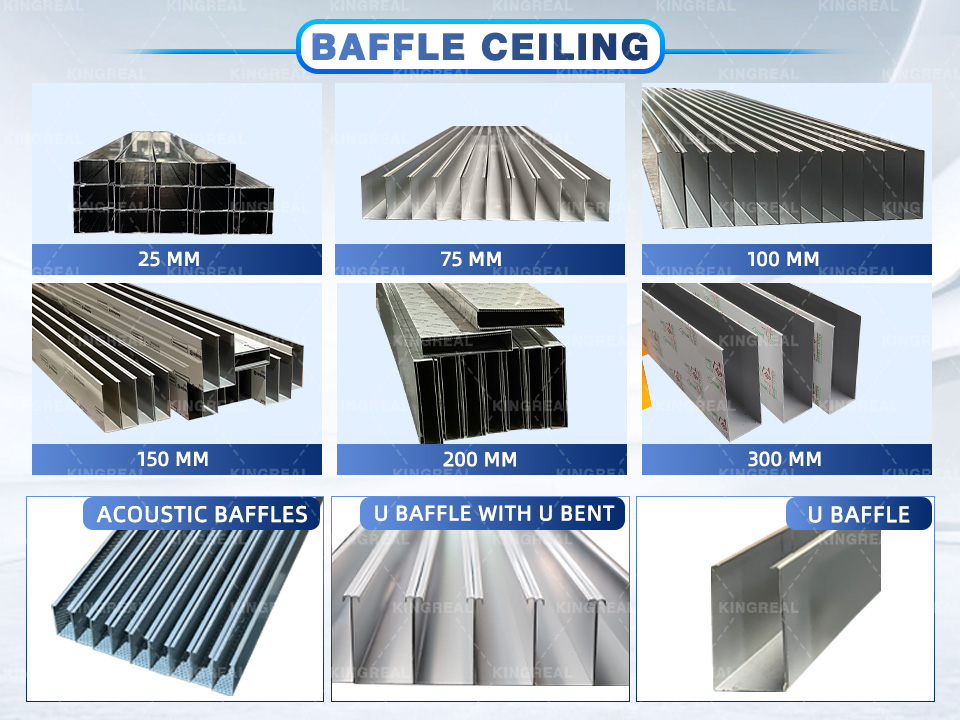

Common Types

Aluminum baffle ceilings can be categorized based on different surface treatments, baffle shapes, and material processes.

By Surface Treatment: It can be divided into fluorocarbon paint, polyester paint, wood grain heat transfer, powder, stone grain, real stone paint, anodizing, and so on.

By Baffle Shape: It can be divided into straight bars, arcs, special-shaped and so on.

By Material Process: It can be mainly divided into aluminum plate aluminum square and aluminum profile square.

Common Parameters

Taking u-shaped aluminum baffle ceiling as an example, common parameters include:

• Base Width: 20mm to 150mm, with increments of 5mm between each width.

• Side Height: 30mm to 180mm, with increments of 5mm between each height.

• Thickness: 0.5mm to 1.0mm.

• Length: Typically, lengths of 1 to 3 meters are ideal, and lengths within 6 meters can be customized.

• Colors: Generally available in solid colors and wood grain colors, with options for custom colors.

(The above parameters are common for most products on the market and are for reference only.)

Advantages of Baffle Ceiling Machine

U baffle machine's features:

(1) Lightweight and Durable: Made from aluminum, metal baffle ceilings are lightweight yet strong and durable, resistant to deformation or damage.

(2) Fire Resistance: They have excellent fire resistance, helping to prevent the spread of fires and ensuring safety for people and property.

(3) Easy Installation and Maintenance: Metal baffle ceilings are installed using a modular system, making installation quick and easy, with convenient maintenance and replacement of damaged parts.

(4) Corrosion Resistance: They are highly resistant to corrosion, not easily affected by moisture, rust, or chemical corrosion, making them suitable for humid or chemically aggressive environments.

(5) Aesthetic Appeal: The smooth, flat surface and simple lines of aluminum baffle ceilings offer a modern look that enhances interior decoration.

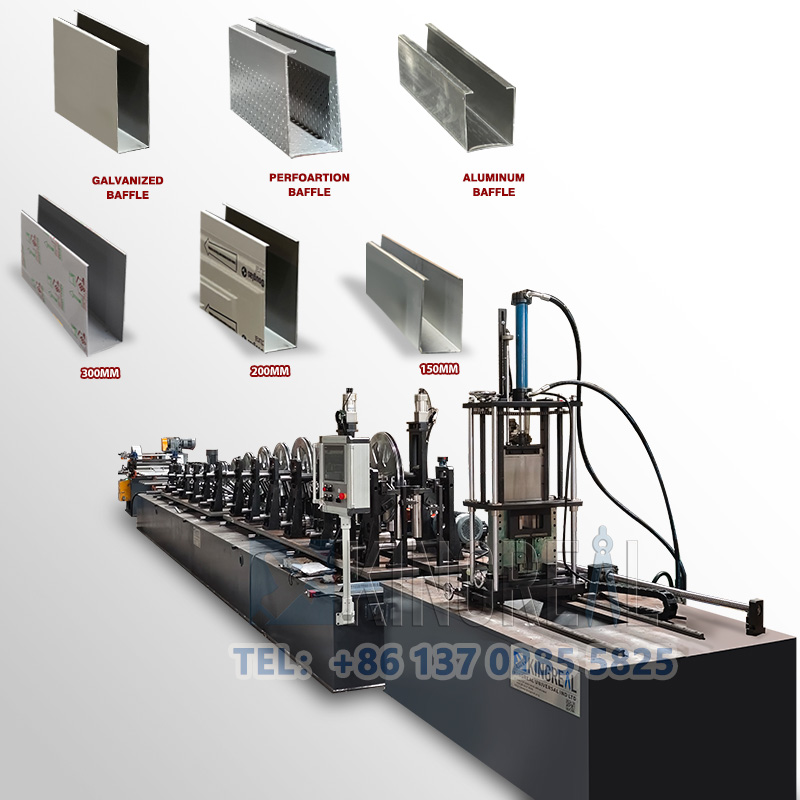

What does KINGREAL CEILING MACHINERY Baffle Ceiling Machine Offer?

1. To meet the production needs of different sizes of baffle ceiling, the u baffle machine can automatically adjust the width to produce different sizes of u baffle ceilings, you do not need to change the machine frequently to produce different sizes of baffle ceiling machines.

2. Customized solution. The 300mm height baffle ceiling machine is customized according to the actual production needs of customer Douglas, KINGREAL CEILING MACHINERY can meet the special needs of customers for u baffle production size. If you have new ideas and needs for baffle production, welcome to send your drawings to KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY designers will customize your baffle ceiling roll forming machine after full communication with you.

3. More efficient production. KINGREAL CEILING MACHINERY baffle ceiling production line uses follow cutting, you only need to enter the required cutting parameters, the system can detect the length of baffle material through the sensor, and control the tool at the right time to cut. The follow cutting can improve cutting efficiency and accuracy, reduce downtime and waste, and greatly improve your productivity.

Various baffle ceiling machines

In modern architecture and interior decoration, baffle ceilings are widely favored for their elegant appearance and excellent functionality. In order to meet customers' different production needs for baffle ceilings, KINGREAL CEILING MACHINERY has launched various types of baffle ceiling making machines with flexible production capacity and diverse design options. The following is a detailed introduction to different types of baffle ceiling machines.

1. Height-adjustable baffle ceiling machine

KINGREAL CEILING MACHINERY's baffle ceiling machine series includes a variety of models with different heights, mainly the following:

150mm height baffle ceiling machine

This model is designed for the production of baffle ceilings with a maximum height of 150mm. This baffle ceiling machine can quickly respond to market demand with its efficient production capacity and precise molding technology.

200mm height baffle ceiling machine

The 200mm baffle ceiling machine can produce baffle ceilings with a maximum height of 200mm. It maintains stable performance during the production process to ensure that the size and shape of each baffle ceiling meet the design requirements.

300mm height baffle ceiling machine

The 300mm baffle ceiling machine is designed according to the special needs of Douglas, a KINGREAL CEILING MACHINERY customer, and is capable of producing baffle ceilings with a maximum height of 300mm. This model is particularly suitable for projects that require large-sized baffle ceilings, providing greater design flexibility and meeting the needs of high-specification ceilings.

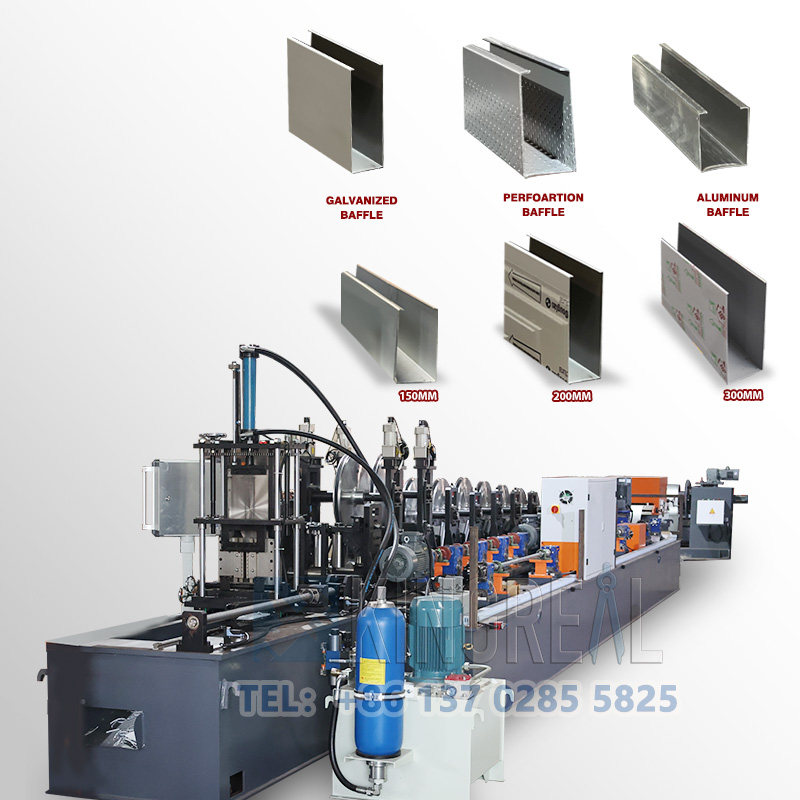

2. Special baffle ceiling machine according to different types

KINGREAL CEILING MACHINERY has also launched a variety of baffle ceiling machines based on different types of baffle ceilings, including:

U-shaped baffle ceiling machine

The U-shaped baffle ceiling machine is dedicated to the production of U-shaped baffle ceilings, suitable for various interior decoration styles. Its design allows the production of a unique U-shaped structure, which increases the layering and visual effect of the ceiling and is widely used in commercial spaces and residential projects.

V-shaped baffle ceiling machine

The V-shaped baffle ceiling machine is used to produce V-shaped baffle ceilings, providing an appearance option different from traditional baffle ceilings. The V-shaped design is not only beautiful, but also enhances the reflection effect of light, adding a touch of brightness to the indoor environment.

U-shaped baffle ceiling machine with u-bent

This machine is specially designed for the production of U-shaped baffle ceilings with u-bent. The folding design makes the baffle ceiling more stable during installation and improves the overall aesthetics. It is suitable for projects with high requirements for aesthetics and functionality.

Conclusion

Because of its superior aesthetics, durability and functionality, aluminum baffle ceiling has been widely used in various construction projects, including commercial space, public facilities, smart home and green building fields. With the continuous development of technology, the design and production process of aluminum baffle ceiling are also constantly innovative to meet the increasingly diversified market needs. Whether it is to enhance the visual effect of the space, to ensure safety, or in terms of environmental protection and energy efficiency, aluminum baffle ceiling has shown its unique advantages.

In the production of aluminum baffle ceiling, it is very important to choose efficient and accurate production equipment. KINGREAL Ceiling Machinery, with its advanced automatedbaffle ceiling roll forming machines, provides flexible, precise and efficient solutions to meet production needs of different sizes and specifications, helping customers increase production efficiency, reduce waste and improve product quality. Whether it is a large commercial project or a customized home improvement, KINGREAL CEILING MACHINERY equipment can provide the perfect support for customers to ensure the high quality of products and production efficiency.

With the continuous development of the market, aluminum baffle ceiling will show its potential in more areas, and KINGREAL CEILING MACHINERY will continue to be committed to providing customers with innovative production technology and quality services to help the long-term development of the industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)