What's function of metal ceiling machine?

2025-02-23 17:00

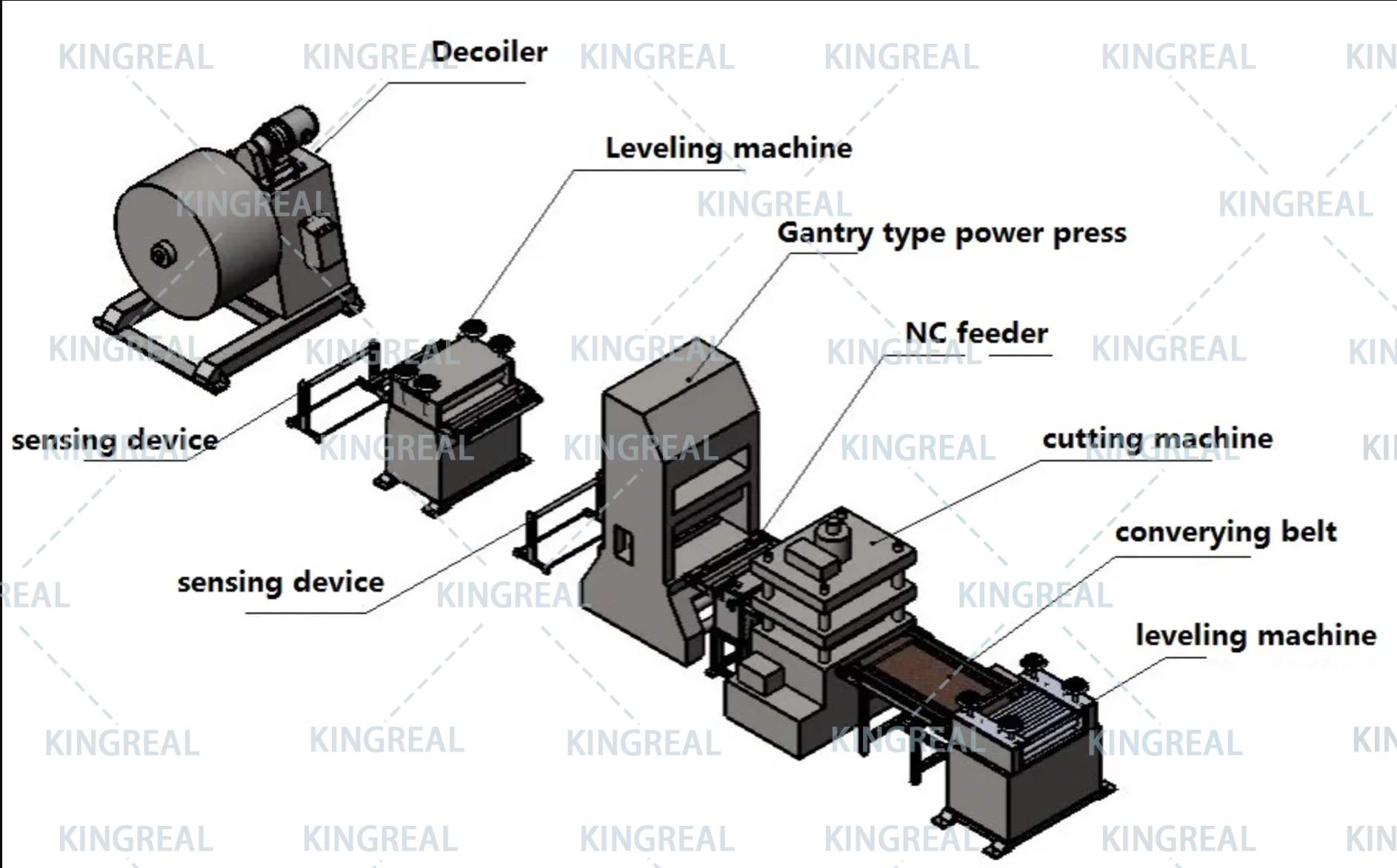

Metal ceiling machine is a kind of equipment specially used to manufacture metal ceilings. Its workflow mainly includes putting metal coils into the metal ceiling production line, and finally producing metal ceilings that meet market demand through processes such as leveling, punching, and cutting. Specifically, the whole process usually includes the following steps:

1. Material preparation: First, prepare the metal coils and check their quality to ensure the smooth progress of subsequent production.

2. Leveling: Put the coils into the leveling machine to ensure that their surface is flat for subsequent processing.

3. Punching: According to the design requirements, punch holes on the metal plate for subsequent installation and use.

4. Cutting: Cut the leveled metal plate into the specified shape and size according to the requirements.

5. Forming and packaging: Finally, the cut metal ceiling is formed and packaged for shipment.

The efficient operation of this series of processes enables the ceiling production line to produce high-quality metal ceilings in a fast and stable manner to meet market demand.

Market demand for metal ceiling making machine

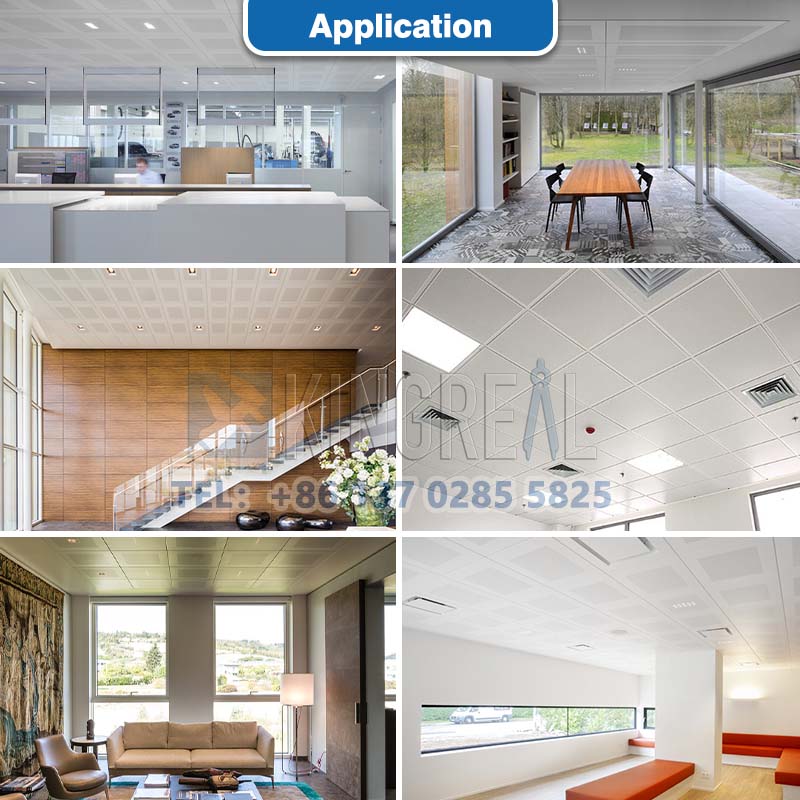

With the continuous advancement of modernization, the demand for metal ceilings in countries around the world is increasing. Whether it is residential, commercial or industrial facilities, ceilings, as an important part of the building, play an indispensable role in almost every building. Specifically, the market demand for ceilings is mainly reflected in the following aspects:

1. The rapid development of the construction industry: With the acceleration of urbanization, countries have invested a lot of resources in infrastructure construction, and the booming construction industry has directly promoted the demand for ceilings.

2. The rise of the decoration market: The development of the decoration market has also prompted the demand for various types of ceilings, including metal ceilings.

3. Improvement of functional requirements: Modern ceilings are not only decorations, but also need to have multiple functions such as sound absorption, fire resistance, and moisture resistance, which also prompts the market to increase the demand for ceilings with excellent performance.

In summary, the demand for ceilings continues to rise, and with it, the demand for metal ceiling production lines has increased sharply. Whether in new buildings or renovation projects, it is particularly important to have an efficient and reliable metal ceiling making machine.

Functions of metal ceiling production line

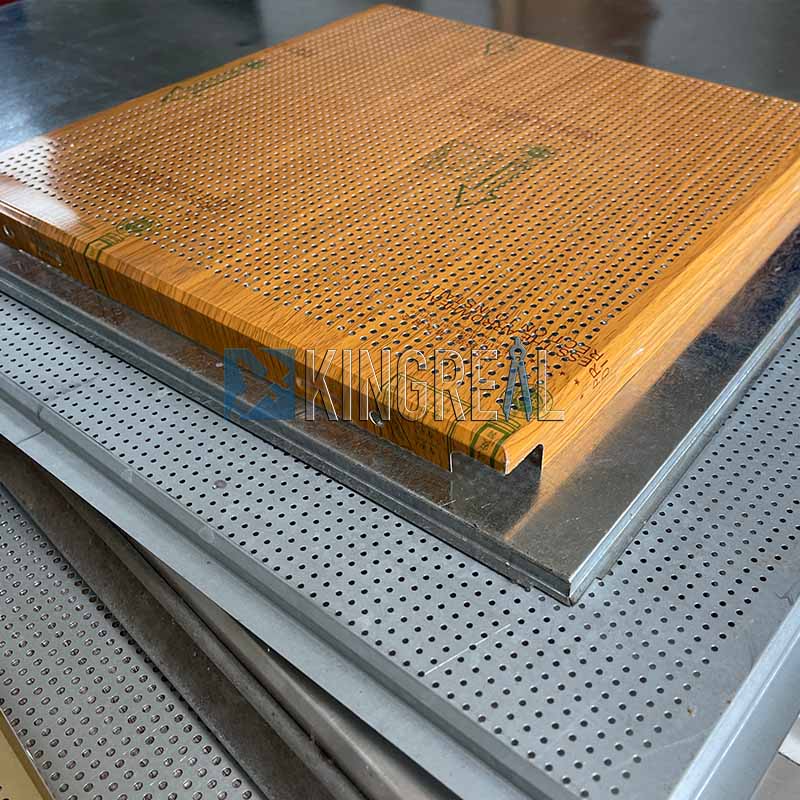

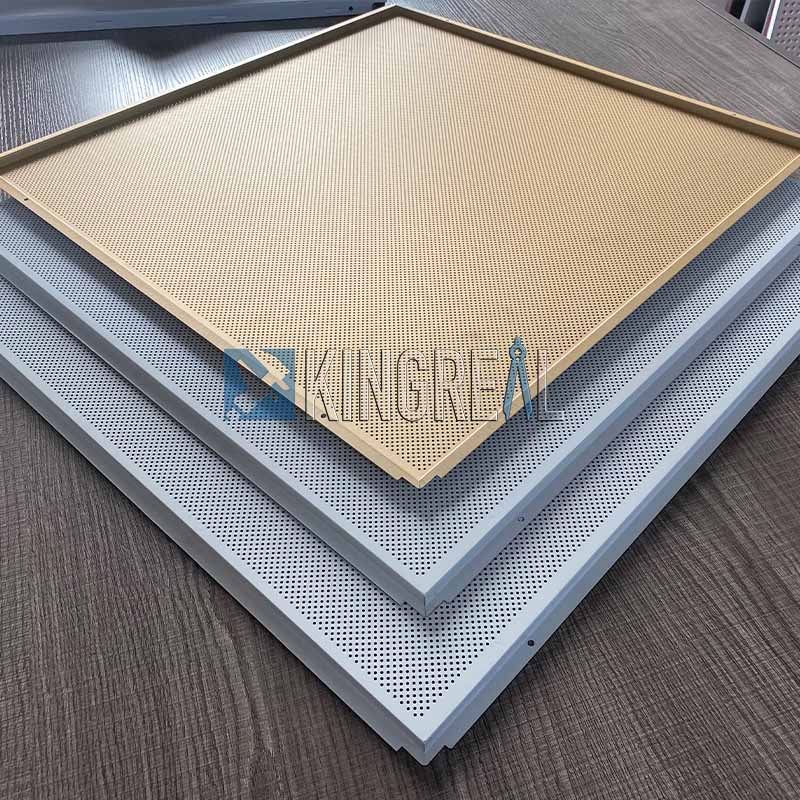

Produce different types of ceilings

KINGREAL CEILING MACHINERY metal ceiling making machine has strong flexibility and can produce various types of ceilings commonly seen in the market, such as clip in, lay in, tegular, etc. If customers have special ceiling production needs, KINGREAL CEILING MACHINERY engineers can also develop customized metal ceiling production line manufacturing solutions based on the drawings provided by customers. This flexibility not only meets the diverse needs of the market, but also allows customers to produce according to specific project requirements.

Produce ceilings of different sizes

In the production process of metal ceilings, the diversity of sizes is an important factor that cannot be ignored. KINGREAL CEILING MACHINERY metal ceiling production line can produce ceilings of various sizes, including 30x30cm, 30x60cm, 30x120cm, 60x60cm, 60x120cm, etc. This allows customers to choose the right size according to actual needs to meet the requirements of different projects. This flexibility not only improves production efficiency, but also enhances customers' market competitiveness.

Automatic metal ceiling making machine

In modern manufacturing, automatic production lines have become an important way to improve production efficiency and reduce labor costs. KINGREAL CEILING MACHINERY provides two types of metal ceiling production lines: fully automatic and semi-automatic. Customers can choose according to their own production scale and production efficiency needs. The fully automatic metal ceiling making machine can achieve a seamless production process, reduce manual intervention, and improve production speed and product consistency; while the semi-automatic metal ceiling production line is suitable for small-scale or flexible production enterprises, which can not only meet customized needs but also control production costs.

Different widths and thicknesses of metal raw materials

Get the latest price? We'll respond as soon as possible(within 12 hours)