Automatic Metal Honeycomb Panel Making Machine

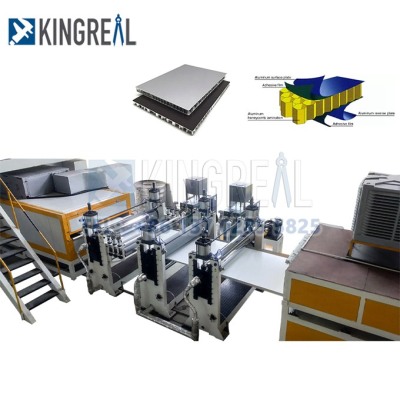

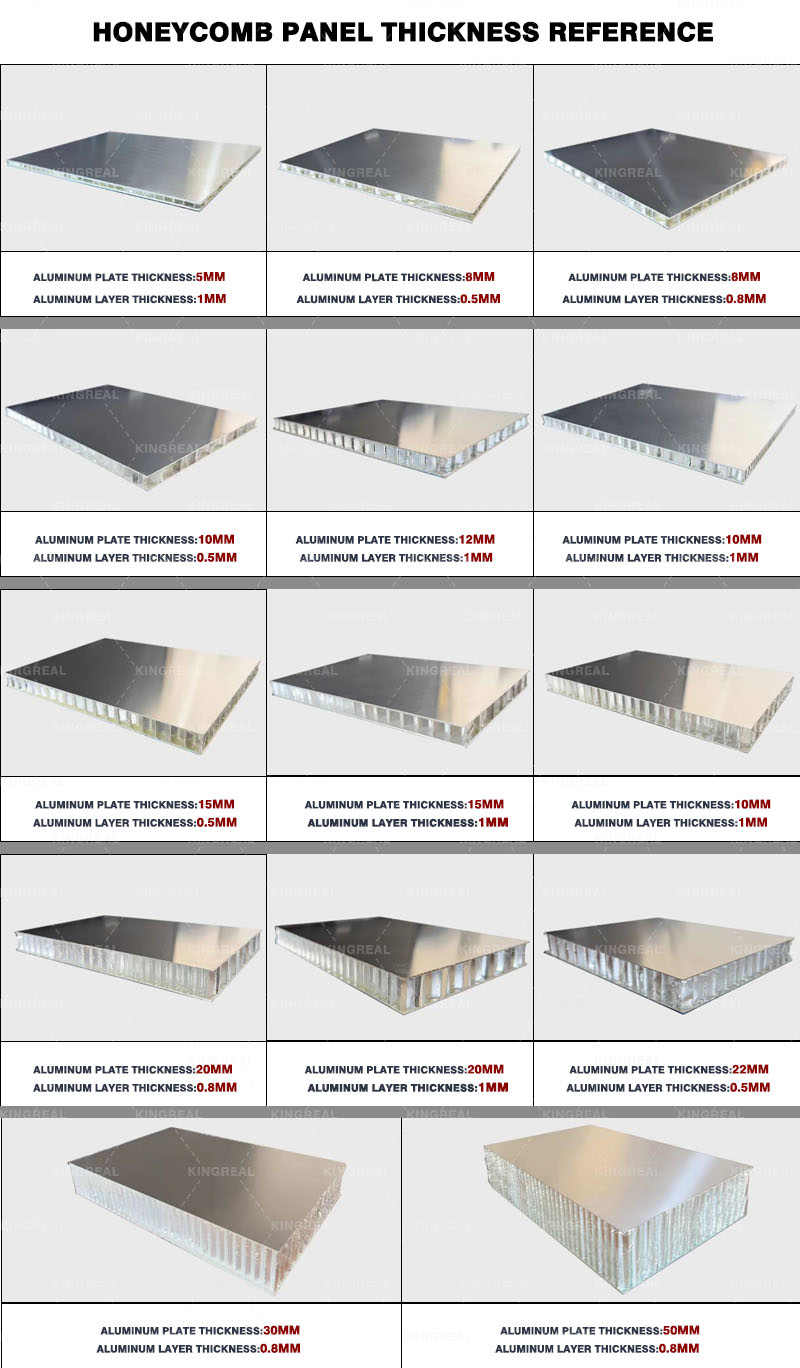

KINGREAL CEILING MACHINERY can customize the production of metal honeycomb panel making machines according to your different production needs. Metal honeycomb panels are the basic panels of metal honeycomb composite panels. These panels can be made of different materials, such as aluminum panels, steel panels, etc. The panel material and honeycomb core material can be selected according to different uses.

- KINGREAL CEILING MACHINERY

- China

- 90

- 9999

Details

Description of Metal Honeycomb Panel Making Machine

Due to its excellent performance, metal honeycomb panels are widely used in many industries. In order to adapt to the growing demand for aluminum honeycomb sheets, KINGREAL CEILING MACHINERY’s technical team has improved the production technology and launched this Metal Honeycomb Panel Making Machine that can be produced efficiently.

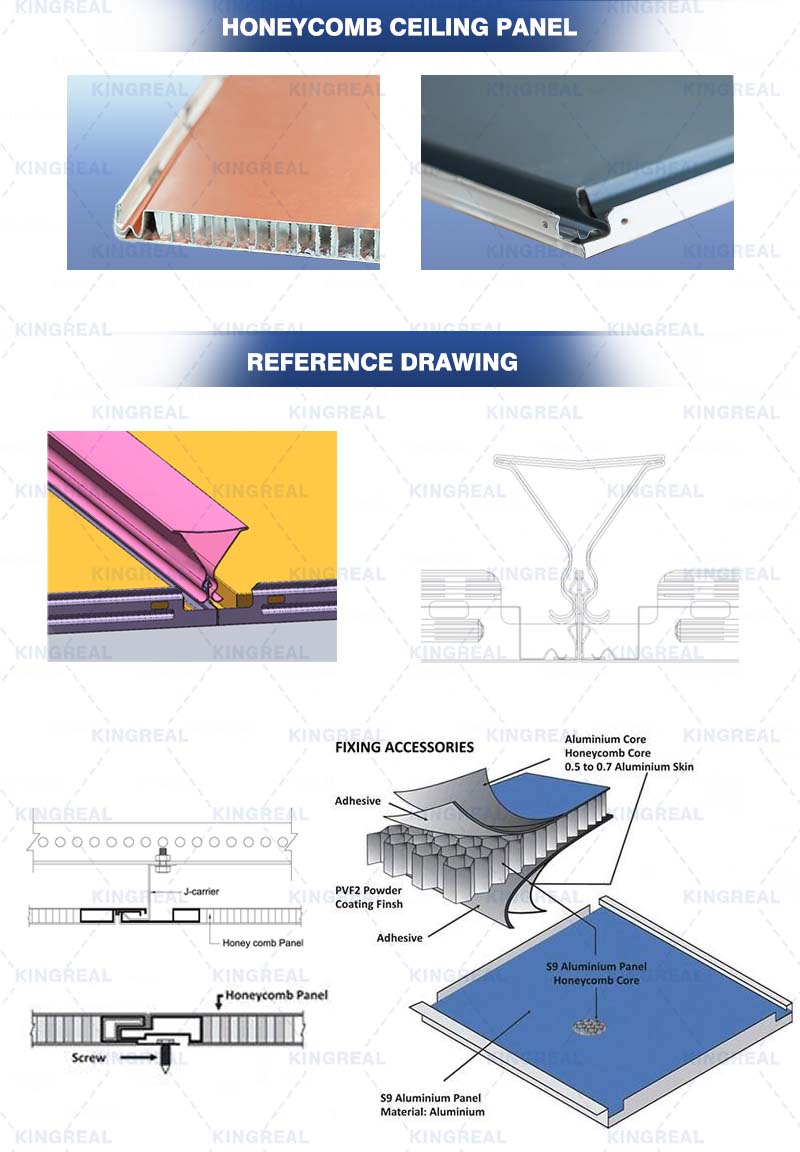

From basic honeycomb metal sheet production to gluing, hot pressing/cold pressing composite honeycomb metal sheet, KINGREAL CEILING MACHINERY can provide you with a complete production solution.

Main Processes of Metal Honeycomb Panel Production Line

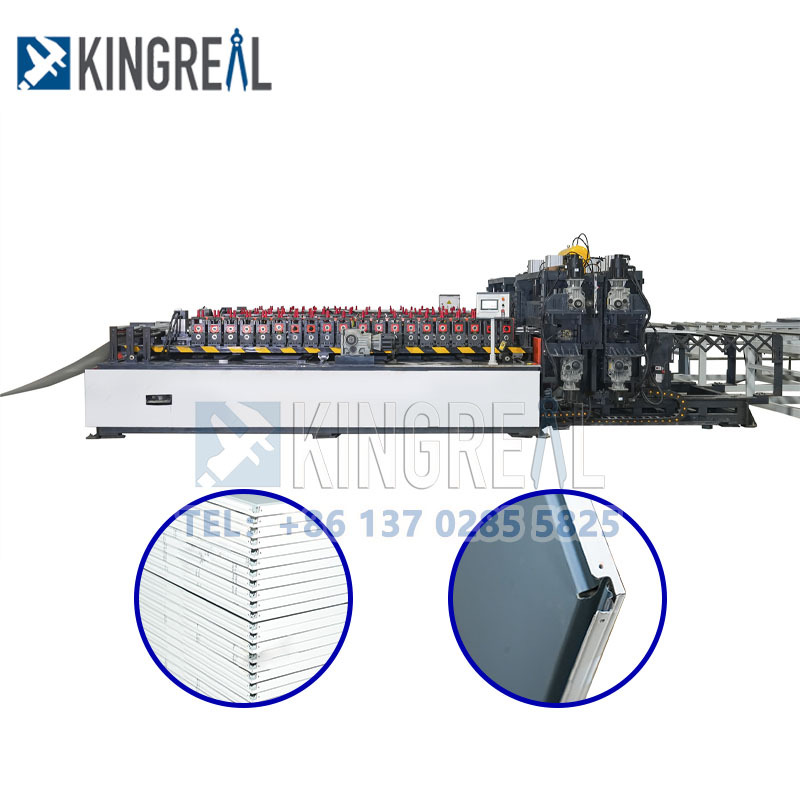

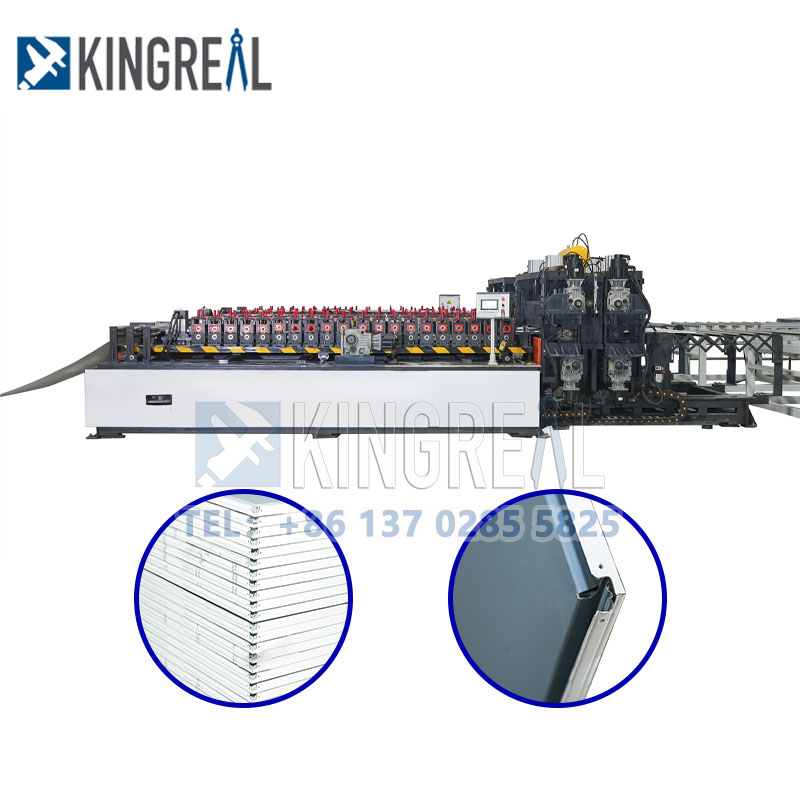

Decoiler - Leveling - Roll Forming And Bending - Cutting And Bending

Specification Of Metal Honeycomb Panel Making Machine

| Raw materials | Aluminum, Steel (Can be customized) |

| Material thickness | surface 0.28mm; back 0.18mm |

| Forming roller | 20 |

| Running speed | 4-6m/min |

| Profile size | 600/900/1200*11.7mm (Can be customized) |

| Profile precision | ±0.2mm |

What KINGEAL Honeycomb Metal Sheet Making Machine Can Do?

1. Easy operation

The width and length of the aluminum honeycomb panels can be adjusted by CNC. The production process is highly automated without the hassle of increasing labor costs.

2. Flexible sizes

The size of aluminum honeycomb panels can be can be customized, you just need to tell KINGREAL CEILING MACHINERY your requirement.

3. Great accuracy of finished metal honeycomb panels

KINGREAL CEILING MACHINERY aluminum honeycomb panels making machine adopts automatic mechanized production method, has a strong stability and consistency of the products produced.

Why Metal Honeycomb Panel is Popular?

1. Lightweight and high strength: The two surface metal honeycomb panel have high structural strength, and the middle metal honeycomb core is inspired by the natural honeycomb structure, making the honeycomb metal sheet light in weight, high in strength and good in rigidity.

2. Sound and heat insulation properties: The honeycomb structure of aluminum honeycomb panels can effectively isolate sound and heat. This is great for interior decoration and insulation.

3. Versatility: According to different uses, it can be made into fireproof honeycomb metal sheet, heat insulation aluminum honeycomb panels, sound insulation metal honeycomb panel, etc. It is widely used in aviation, aerospace, construction, automobile and other fields.

Complete Metal Honeycomb Panel Production Solution

Honeycomb metal sheet are metal sheets of composite metal honeycomb panels. After R&D and testing by the KINGREAL CEILING MACHINERY technical team, KINGREAL CEILING MACHINERY has optimized the technical details of the composite metal honeycomb panel production line. From the production of basic panels to the final molding of composite metal honeycomb panels, KINGREAL CEILING MACHINERY can tailor a suitable machine production solution for you.

About Us

To integrate R&D, KINGREAL CEILING MACHINERY has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of KINGREAL CEILING MACHINERY customers also choose to visit our factory to observe the production of machines and communicate with us face to face. KINGREAL CEILING MACHINERY is looking forward to reaching long-term and stable relationships with customers around the world with KINGREAL CEILING MACHINERY's professional capability and consistent level of service!

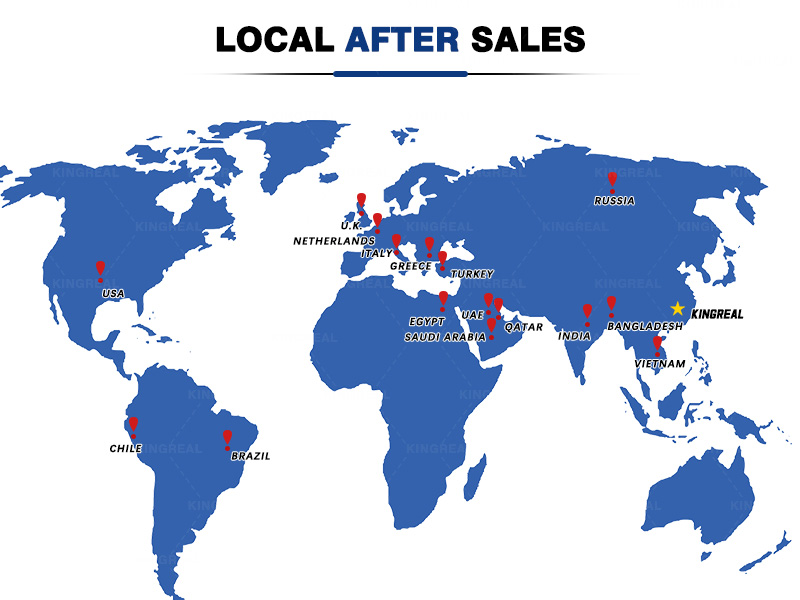

Kingreal CEILING MACHINERY Localized After-sales Service

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL CEILING MACHINERY has been insisting on doing. The global localization service point is under construction.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)