Full Auto Clean Room Sandwich Panel Production Line

Full Auto Clean Room Sandwich Panel Production Line adopts high-tech design to realize fully automatic production, which can minimize the labor cost and get better production efficiency. Welcome to contact us.

- KINGREAL CEILING MACHINERY

- China

- 100 Days

- 9999

Details

Production Line Description

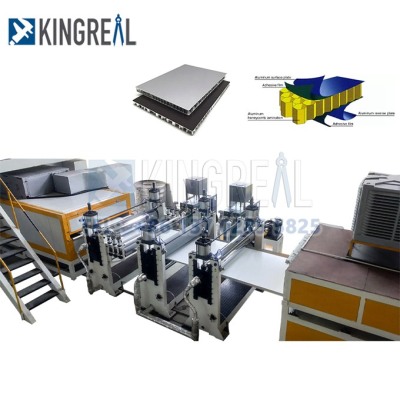

Full Auto Clean Room Sandwich Panel Production Line is a kind of equipment used to produce clean room sandwich panel. The clean room sandwich panel is a kind of building material composed of color steel plate and sandwich material, which is commonly used in the manufacture of clean room, cold storage, industrial plant and other places that need heat preservation, sound insulation and fireproof performance.

The design and operation of a clean room sandwich panel production line requires consideration of factors such as material selection control of the processing process, and operation and maintenance of the equipment to ensure the production of sandwich panel products that meet the requirements. KINGREAL will develop a customized production plan based on the customer’s actual production needs as well as existing equipment to meet the customer’s production needs.

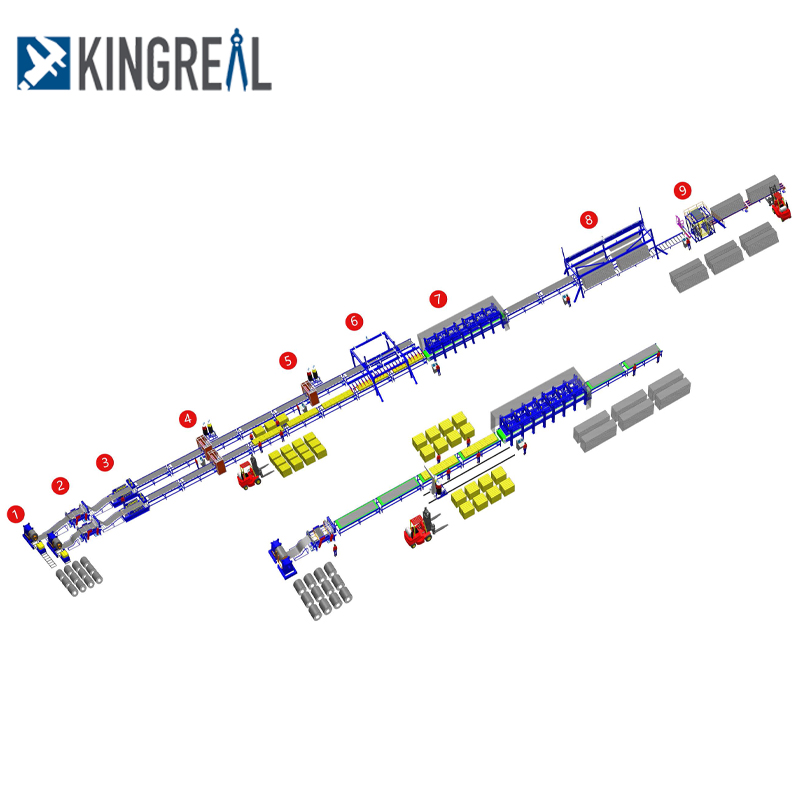

Working Process Of Clean Room Sandwich Panel Production Line

Hydraulic Decoiler -- Leveler Device -- Box Plate Roll Forming Machine -- Sandwich Panel Glue Spraying System -- Glass Magnesium Board -- Conveying And Turning -- High Pressure Machine -- Stacking Machine -- Packing Machine

Main Component Detail

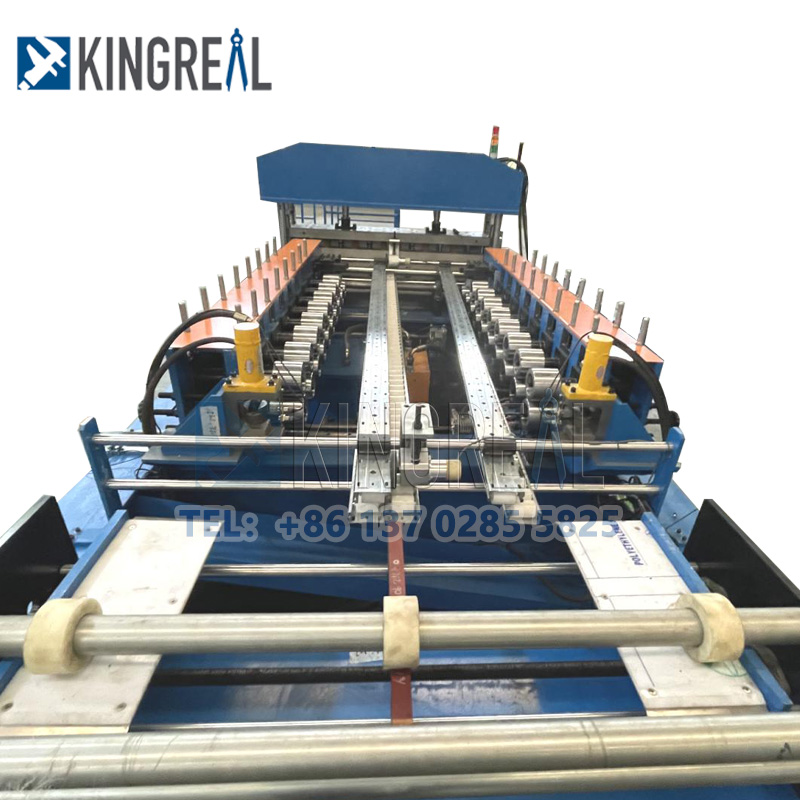

①Box Plate Roll Forming Machine

This Equipment includes 3T manual feeding device, leveling device, transmission device, forming roller conveyor and main machine (including guiding platform), cutting device after forming, hydraulic system and finished product pallet device.

When loading, the steel rolls are loaded into the inner-supported opening frame and braced. Then, the sheet is correctly introduced into the leveling device through the two-roller nip feed, and after roll forming, it passes through the post-forming cutting device, and finally comes out of the sheet through the finished product pallet device.

②Sandwich Panel Glue Spraying System

Gluing equipment is essential in purified sandwich panel production line. Gluing equipment is mainly used to spread the glue evenly on the surface of the sandwich panel to ensure the bonding quality and stability of the sandwich panel.

The function of the glue drenching machine is to drench one-component glue or two-component glue on the surface of the work-piece with precise measurement and uniformity.

It can be equipped with automatic feeding, automatic heating, automatic cleaning, nitrogen filling protection, over-pressure alarm and other functions according to the characteristics of the glue.

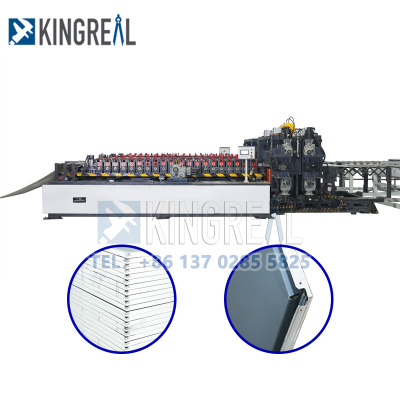

③High Pressure Machine

The high press equipment consists of main machine, hydraulic drive system, iron conveyor belt carrier template, carrier template support, carrier template heating system, electric control system and so on. In order to meet the requirements of foaming material process, a set of oil heating system is configured in the production line for heating the template of the laminating machine.

Depending on the production requirements, KINGREAL CEILING MACHINERY can offer customization of individual components as well as the design of other matching equipment. Feel free to contact us!

Final Product

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)