Full Automatic Aluminum Honeycomb Panel Production Line

KINGREAL CEILING MACHINERY has been specializing in the sheet forming industry for more than 20 years, designing different production solutions for our customers. With the KINGREAL CEILING MACHINERY Aluminum Honeycomb Panel Machine, it is still possible to offer customers a wide range of production possibilities.

- KINGREAL CEILING MACHINERY

- China

- 60

- 9999

Details

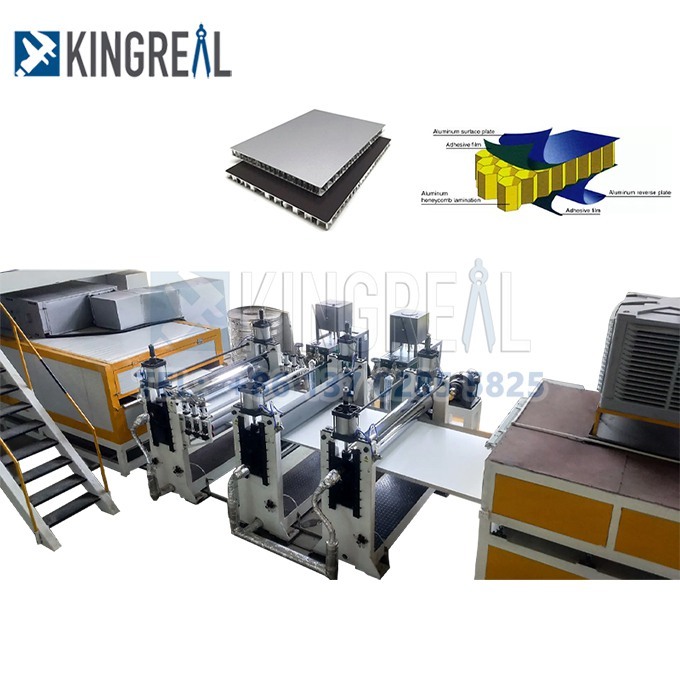

Description Of Aluminum Honeycomb Panel Production Lines

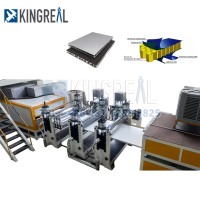

KINGREAL CEILING MACHINERY aluminum honeycomb panel production line is a general term for the equipment and processes used to manufacture honeycomb panels. This production line usually includes processes such as honeycomb core material preparation, panel coating, core lamination, cutting and packaging.

Honeycomb panels are made by sandwiching a honeycomb structure between two layers of panels, and this material is widely used in construction, transportation, decoration and other fields. Aluminum honeycomb panel forming machine can realize efficient, stable and automatic production process, which greatly improves the production efficiency and quality of honeycomb panels.

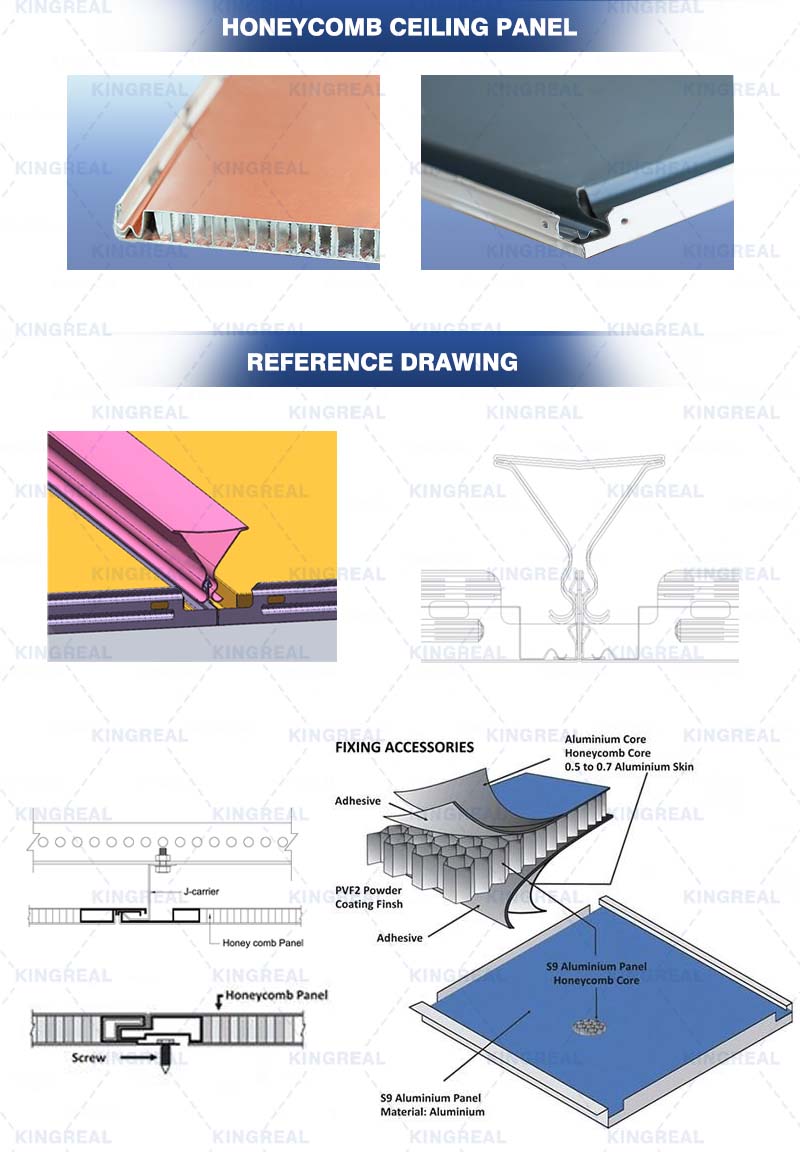

Structure Of Honeycomb panel

★Fluorocarbon Spraying Type Baking Finish

★Chromated Layer

★Aluminum Plate

★Adhesive Film

★Aluminum Honeycomb Core

★Adhesive Film

★Polyester Baking Finish

Working Procedure Of Aluminum Honeycomb Panel Production Line

Expanding

↓

Calender

↓

Laminating

↓

Cooling

↓

Leveling

↓

Trimming

↓

Cutting

↓

Stack

Technical Specification

| Coil Thickness | 0.3-1.0mm |

| Coil Weight | 3T |

| Product Thickness | Honeycomb Plate 5-30mm |

| Design Machine Column Speed | 0-8m/min |

| Production Speed | 2-6m/min |

| Roll Width Range | 800-1600mm |

| Machine Power | 538KW |

| Dimension | 4000*380*300cm |

Advantage Of This Production Line

Efficient production

Honeycomb panel forming machine adopts automatic production method with high production efficiency, which can quickly manufacture a large number of honeycomb panel products.

Cost saving

Compared with traditional manual production, honeycomb board forming machine can reduce labor cost and improve production efficiency, thus reducing production cost.

High product quality

Honeycomb panel forming machine adopts mechanized production method, and the products produced have high consistency and stability, which can meet the customers‘ requirements for product quality.

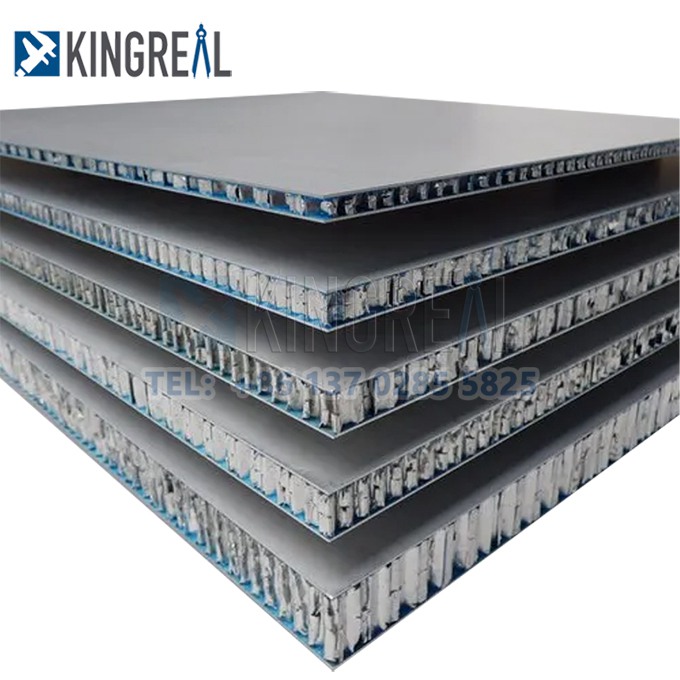

Application Of Honeycomb Panel

Honeycomb panels are widely used in many fields such as furniture manufacturing, building decoration, automobile manufacturing, aerospace, etc. The following are the main features of aluminum honeycomb panels:

1. Lightweight and durable: The honeycomb core of metal honeycomb panel makes them very lightweight, yet still provides excellent strength. This makes metal honeycomb panels ideal for use in sectors such as aerospace, automotive and construction.

2. Sound and heat insulation properties: The honeycomb structure of aluminum honeycomb panels can effectively isolate sound and heat. This is great for interior decoration and insulation.

3. Easy to install and maintain: The lightweight nature of metal honeycomb ceiling panel makes them easy to handle and install. Additionally, cleaning and maintenance are relatively simple.

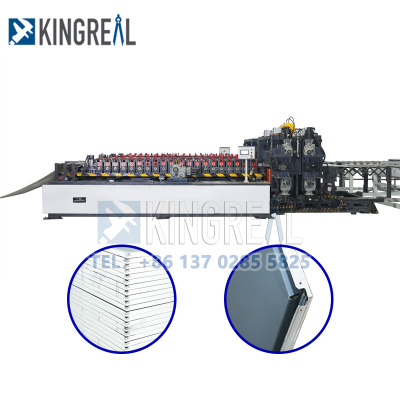

Complete Metal Honeycomb Panel Production Solution

KINGREAL CEILING MACHINERY focusing on the production of metal processing production over 20 years, we can provide a complete solution of metal sheet system production, including metal tile and metal tile carrier.

KINGREAL CEILING MACHINERY can provide Spring Tee Roll Forming Machine for producing carrier of metal honeycomb panel. Combination of Metal Honeycomb Panel Production Line and Spring Tee Roll Forming Machine is convenient for your metal honeycomb panel system production and favorable to improve product consistency.

KINGREAL CEILING MACHINERY EXHIBITION

KINGREAL CEILING MACHINERY participates in domestic and international exhibitions, and are committed to providing customers with customized machine manufacturing solutions. KINGREAL CEILING MACHINERY's featured machines include:

- Metal ceiling production line

- Metal sheet perforation line

- Linear strip ceiling machine

- False ceiling channel machine

......

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)