PU Continuous Sandwich Panel Production Line

KINGREAL CEILING MACHINERY has been in the field of plate manufacturing for more than two decades and is able to provide high quality PU Continuous Sandwich Panel Production Line, which can produce Polyurethane (PU) foam panel.

- KINGREAL CEILING MACHINERY

- CHINA

- 100 Days

- 9999

Details

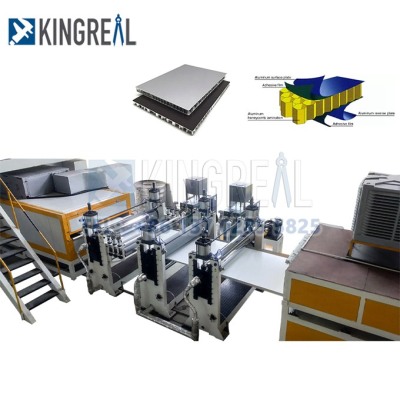

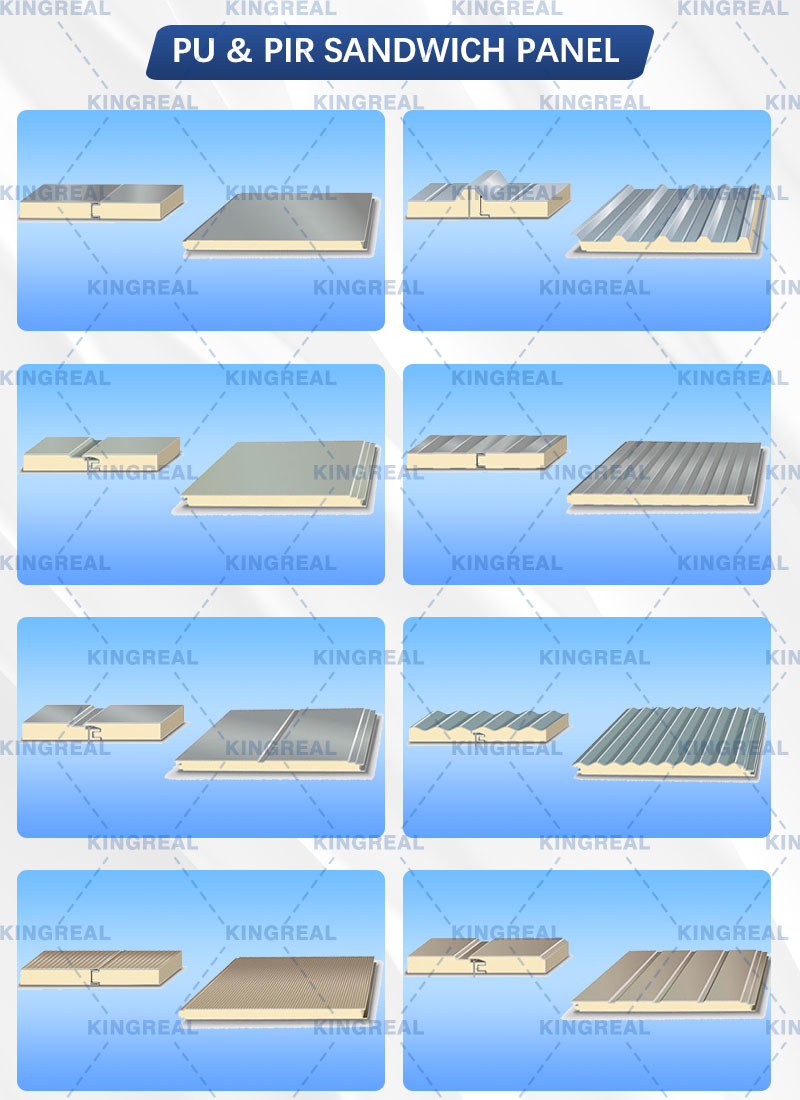

What Is PU Sandwich Panel?

PU sandwich panel is a kind of sandwich panel made of polyurethane (Polyurethane) foam material, also known as polyurethane sandwich panel. It consists of a layer of polyurethane foam sandwiched between two layers of metal sheets. Polyurethane foam material has good thermal insulation, heat insulation and sound absorption properties, so PU sandwich panel has excellent thermal insulation effect.

It is commonly used in the external walls of buildings, roofs, cold storage, workshops and other places of thermal insulation and fire retardant materials.

Machine Description

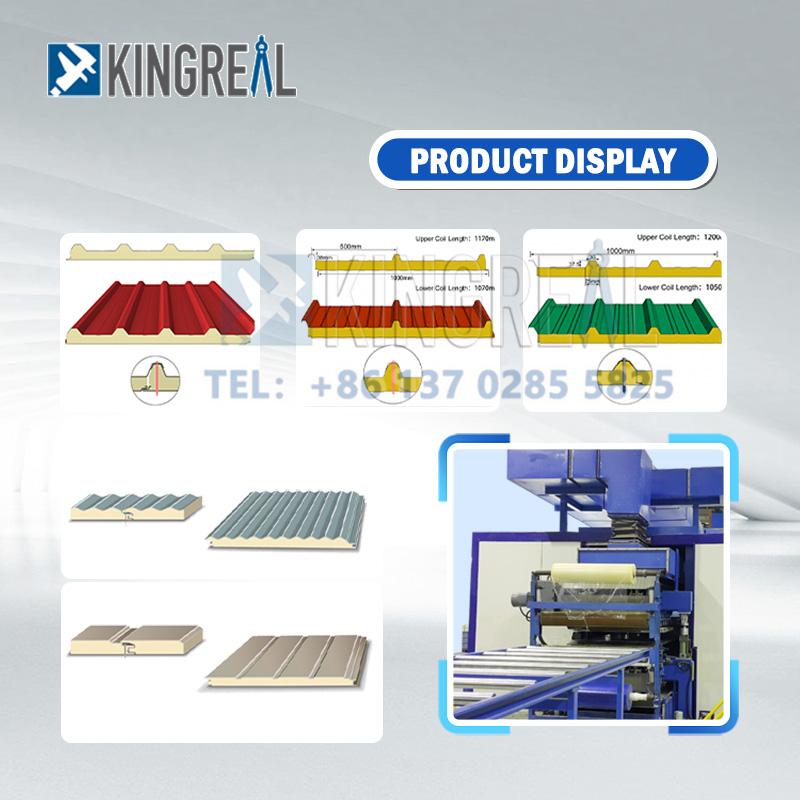

In order to meet the needs of factories in different industries for the production of PU laminates, KINGREAL CEILING MACHINERY specializes in the production of PU Continuous Sandwich Panel Production Line, which can realize efficient, continuous and auto production, improve production efficiency and product quality.

At the same time, the production line can also be customized according to customers’ needs, producing sandwich panels with different specifications, thicknesses and colors.

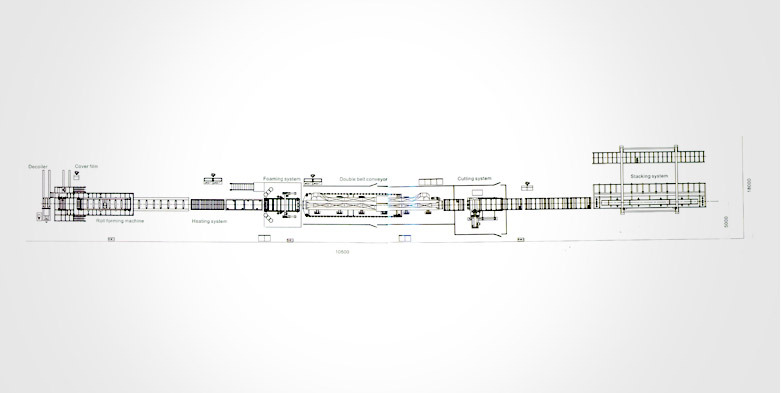

Working Process Of PU Continuous Sandwich Panel Production Line

Sheet Coil Material Decoiler -- Filming Slitting And Cutting -- Main Roll Forming Machine For Sheet Panel -- Preheating Oven -- PU Foaming System -- Double Belt Curing System -- Band Saw Cutting System -- Cooling System -- Stacking System -- Packing System

Main Technical Specification

| Suitable Raw Material | Color Steel/Stainless Steel/Aluminum Sheet |

| Thickness(mm) | 0.4-0.8(Steel)/ 0.35-0.6(Stainless Steel) |

| Width(mm) | ≤1250 |

| Weight(T) | 10T(Max) |

| Panel Length(mm) | 2000-18000 |

| Panel Width(mm) | 600-1200 |

| Panel Thickness(mm) | 30-200/250 |

| Production Speed(m/min) | 3-7(adjustable) |

| Valid Length Of Double belt Conveyor(mm) | 16000-40000 |

| Work Pressure On Pouring Foam(Bar) | 150-200 |

| Total Power(KW) | 200 |

Main Components Detail

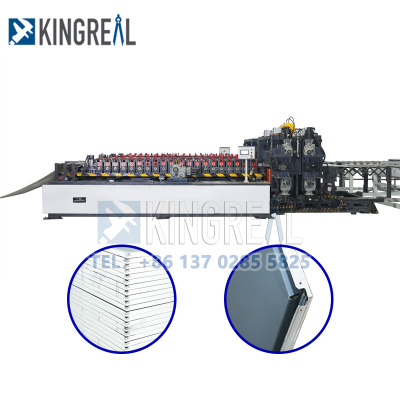

1. Main Roll Forming Machine

The PU Continuous Sandwich Panel Production Line Roll Forming System incorporates a double head roll forming machine specifically designed for the production of upper layer profiles. This machine is equipped with two sets of forming rollers, ensuring efficient and precise shaping of the profiles.

Additionally, the upper roll forming machine is complemented by a guiding system, a transmission system, and a sturdy frame, all of which contribute to its seamless operation.

2. PU Foaming System

The accessories for the foaming system consist of the sheet transmission conveyor, adhesive tape sealing device, and sponge sealing device.

3. Double Belts System

The Double Belts System (DBL) serves as an effective solution to address the issue of foaming expansibility by ensuring its solidity and determining the panel thickness and production speed. The side belt, on the other hand, plays a crucial role in overcoming horizontal expansion, determining the panel width, and providing guidance to the panels.

PU Continuous Sandwich Panel Production Line Features

High degree of automation: PU sandwich panel molding machine adopts PLC control system, which can realize automatic production, reduce manual operation and improve production efficiency.

High molding precision: the molding machine has precise temperature control and pressure control system, which can ensure the molding precision and stable quality of sandwich panel.

Product Quality Is Guaranteed

1. The production line adopts hot air circulation heating furnace to ensure the stability of PU material foaming and curing within the control range, ensuring high quality of the laminated panels;

2. adopting high pressure foaming system, even foaming, accurate measurement and high stability, environmentally friendly process for composite production.

Application

PU sandwich panels are widely used in many fields, mainly including:

Construction industry: used for walls and roofs of industrial plants, warehouses, cold storage and commercial buildings, providing excellent thermal insulation and structural strength.

Cold chain logistics: used in refrigeration and freezing equipment to ensure temperature control of perishable items such as food and medicine.

Transportation: used in containers, refrigerated trucks and transportation equipment to provide thermal insulation and ensure the quality of goods during transportation.

Indoor decoration: used in interior walls and ceilings of places such as shopping malls, supermarkets and exhibition halls to enhance aesthetics and functionality.

Clean room: used in the walls and ceilings of clean rooms in the pharmaceutical, electronics and food industries to meet the requirements of special environments.

The main function of sandwich panels is to provide excellent thermal insulation, heat insulation and sound insulation. At the same time, they have the advantages of light weight, high strength, easy installation and strong durability, making them perform well in a variety of applications.

KINGREAL CEILING MACHINERY's Service

KINGREAL CEILING MACHINERY is a machine manufacturer with more than 20 years of rich experience, focusing on design, R&D and production, providing customers with comprehensive service solutions to ensure that every customer can enjoy high-quality products and professional support.

24-hour Response

KINGREAL CEILING MACHINERY has a 24-hour online customer service team. The team members have undergone rigorous professional training and have an in-depth understanding of machine parameters and other related information. They can not only respond to customer inquiries quickly, but also provide accurate solutions to ensure that customers can get timely help and support at any time.

Customer Visit

KINGREAL CEILING MACHINERY warmly welcomes customers from all over the world to visit the factory. KINGREAL CEILING MACHINERY staff will provide pick-up and drop-off services, and accompany customers to visit all aspects of the factory, including raw material workshops, processing workshops, assembly workshops and trial workshops. During the visit, customers will be able to more intuitively understand KINGREAL CEILING MACHINERY's production process and quality control standards, thereby enhancing their trust in KINGREAL CEILING MACHINERY.

Offline Installation

KINGREAL CEILING MACHINERY provides customers with considerate offline installation services. When the machine arrives at the customer's factory, KINGREAL CEILING MACHINERY will dispatch professional engineers to the site for installation and provide detailed training for the customer's operators to ensure that they can master the operation and maintenance skills of the machine. This series of services not only improves the customer's experience, but also provides strong guarantees for subsequent production.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)