How to Ensure Every Baffle Meets the Standards?

2024-11-15 11:23

Video About Baffle Ceiling Machine

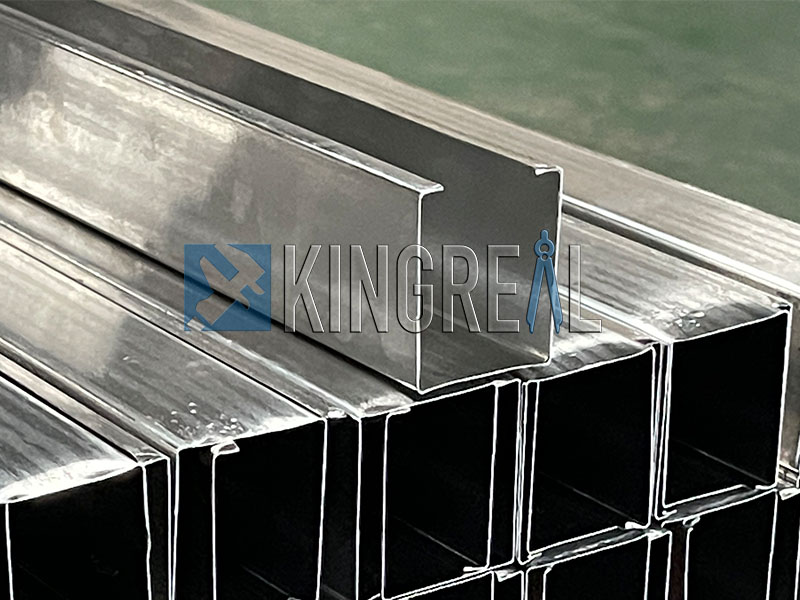

In the modern construction and decoration industry, the baffle ceiling machine is widely used in ceiling systems, partition walls, and other metal decoration applications. With the increasing demands for product quality in the construction sector, the production quality and precision of the baffle ceiling production line have become key concerns for manufacturers. Ensuring that each baffle meets the required standards is a challenge that producers must address.

This article will explore how manufacturers can ensure that every baffle produced by the baffle ceiling machine adheres to industry standards. We will discuss quality control standards, production process optimization, equipment selection, and maintenance, with a special focus on how advanced equipment like the u baffle machine can help improve production quality.

Quality Control Standards for the Baffle Ceiling Machine

Quality control standards are crucial throughout the baffle production process. The production quality of the u baffle machine must comply with strict guidelines, covering baffle dimensions, shape, surface finish, and durability. These standards ensure that the baffles are not only aesthetically appealing and functional but also stable and long-lasting during use.

As a professional ceiling forming machine manufacturer, KINGREAL CEILING MACHINERY customizes production standards based on customer requirements and environmental conditions. For instance, baffles used in ceiling systems may have higher requirements for compression resistance and corrosion resistance, while decorative baffles may focus more on appearance and ease of forming.

To ensure consistent quality, every step of the u baffle ceiling roll forming machine production process must be carefully controlled, from material selection to equipment calibration and process optimization.

How to Ensure Precision in Size and Shape of Baffles?

Precision is the foundation for maintaining the quality of baffles. The u baffle ceiling roll forming machine plays a key role in achieving high precision. These forming machines use precise CNC systems to adjust parameters, ensuring that every baffle meets the specified dimensions, shape, and surface smoothness.

The cold-rolled forming process employed by KINGREAL CEILING MACHINERY's u baffle machine efficiently and accurately transforms metal sheets into baffles. During the forming process, the machine automatically adjusts speed, pressure, and temperature to ensure stability and consistency. By utilizing high-precision molds and automation systems, the production accuracy of the baffles is significantly improved.

Additionally, regular inspection and maintenance of the equipment are crucial to preserving baffle precision. Equipment wear and tear can lead to dimensional deviations, so routine calibration and replacement of worn parts help prevent these issues.

How to Improve Baffle Quality Through Production Processes?

The quality of baffle production depends not only on equipment precision but also on the optimization of production processes. The baffle ceiling production line is highly automated, enabling more efficient and precise production processes.

With advanced automated control systems, the production line can automatically adjust production parameters based on different baffle specifications, ensuring consistent forming quality. Additionally, the production line is equipped with real-time quality inspection systems that monitor dimensions, surface quality, and other factors. If any defects are detected, the system immediately halts production to prevent defective products from reaching the market.

The optimization of production processes also includes material pre-treatment, machine calibration, and temperature control during forming. A well-designed process increases production efficiency, reduces scrap rates, and lowers overall production costs.

How to Ensure Baffle Quality Through Equipment Selection and Maintenance?

Equipment selection and maintenance are essential for ensuring high-quality baffles. Choosing the right forming equipment guarantees that baffles meet the required precision and consistency. KINGREAL CEILING MACHINERY's u baffle ceiling roll forming machine is renowned for their advanced technology and reliable performance, making them the preferred choice for many baffle manufacturers. Our equipment is ISO9000 certified and meets international CE certification standards, ensuring quality and reliability.

Furthermore, regular maintenance is key to maintaining production quality. Over time, equipment wear and part degradation can affect performance. Routine inspection, cleaning, and calibration help maintain machine precision, minimize downtime, and improve production efficiency. In case of equipment failure, KINGREAL CEILING MACHINERY also provides technical support and after-sales service to resolve issues quickly.

How to Ensure the Surface Quality of Baffles?

The surface quality of baffles directly affects both their appearance and longevity. The u baffle machine ensures smooth and consistent surface finishes during the production process. By employing advanced coating technologies and surface treatment processes, the baffle surface can be made smoother, reducing defects such as scratches and dents.

For certain projects with specific requirements, surface treatments like spray coating or anodizing may be applied to enhance corrosion resistance and improve aesthetics. These treatments can significantly extend the lifespan of baffles and improve overall quality.

How to Ensure Baffles Meet Standards Through Quality Testing?

To ensure the quality of baffles, multiple quality checks are performed throughout the production process. The baffle ceiling production line is typically equipped with automated quality inspection equipment, including dimensional checks and surface quality monitoring systems. These systems continuously track each baffle during production, alerting operators if issues arise.

In addition, manual sampling inspections are conducted periodically by technicians to ensure that the baffles meet design specifications. If any non-compliant products are found, the production line will be adjusted to prevent further issues. Only machines that pass thorough testing, including checks for high precision, are shipped to customers.

Conclusion

Quality control in the operation of the baffle ceiling machine is key to ensuring every baffle meets the required standards. By selecting the right equipment, optimizing production processes, and strictly controlling every step of production, manufacturers can effectively guarantee product quality. Using advanced, high-precision equipment like the u baffle machine, manufacturers can produce baffles with stable quality and superior performance to meet diverse customer needs.

As a professional supplier of baffle ceiling machines, KINGREAL CEILING MACHINERY is committed to providing high-quality equipment and comprehensive after-sales service, helping clients gain a competitive advantage in the market. If you have any needs, feel free to contact KINGREAL CEILING MACHINERY for consultation!

FAQ

How can common quality issues be avoided during baffle production?

Common quality issues include incorrect dimensions, surface scratches, warping, and unevenness. These problems can be effectively prevented by optimizing production processes, using high-precision equipment like the u baffle ceiling roll forming machine, and incorporating real-time quality monitoring systems on the production line.

How does the precision of production equipment ensure consistency in baffles?

By selecting high-precision forming equipment such as the u baffle machine, and utilizing advanced CNC systems to control the production process, the dimensions and shapes of baffles can be maintained with high consistency. Regular calibration and maintenance of the equipment further ensure long-term consistency and stability.

How does surface treatment technology affect baffle durability?

Surface treatments like anodizing and spray coating not only improve the appearance of baffles but also enhance their corrosion resistance and wear resistance. These processes are especially important for baffles used in humid or highly corrosive environments and can significantly extend the baffle's lifespan.

What is the importance of ISO9000 certification for baffle production equipment?

ISO9000 certification indicates that the baffle forming machine manufacturer has a stringent quality management system in place, ensuring the production of equipment that meets international standards. Choosing an ISO9000-certified supplier guarantees that the equipment will produce baffles that meet the required quality specifications.

How to choose the right baffle manufacturer?

When selecting a baffle manufacturer, consider factors like their equipment technology, quality control system, and after-sales service capabilities. Manufacturers with ISO9000 and CE certifications, like KINGREAL CEILING MACHINERY, are typically reliable and capable of providing high-quality baffle forming equipment and robust after-sales support.

Get the latest price? We'll respond as soon as possible(within 12 hours)