How to extend the life of false ceiling channel machine?

2025-02-09 17:00

How to extend the service life of the false ceiling channel machine, so that the machine can run smoothly and produce stably, avoid shutdowns due to machine failures, or high replacement costs due to machine damage, is an important issue that every factory will think about.

This article will introduce in detail the effective methods to extend the service life of omega channel machine to help enterprises maximize the economic benefits of the equipment.

Machine manufacturing stage: selection of high-quality materials and rigorous manufacturing processes

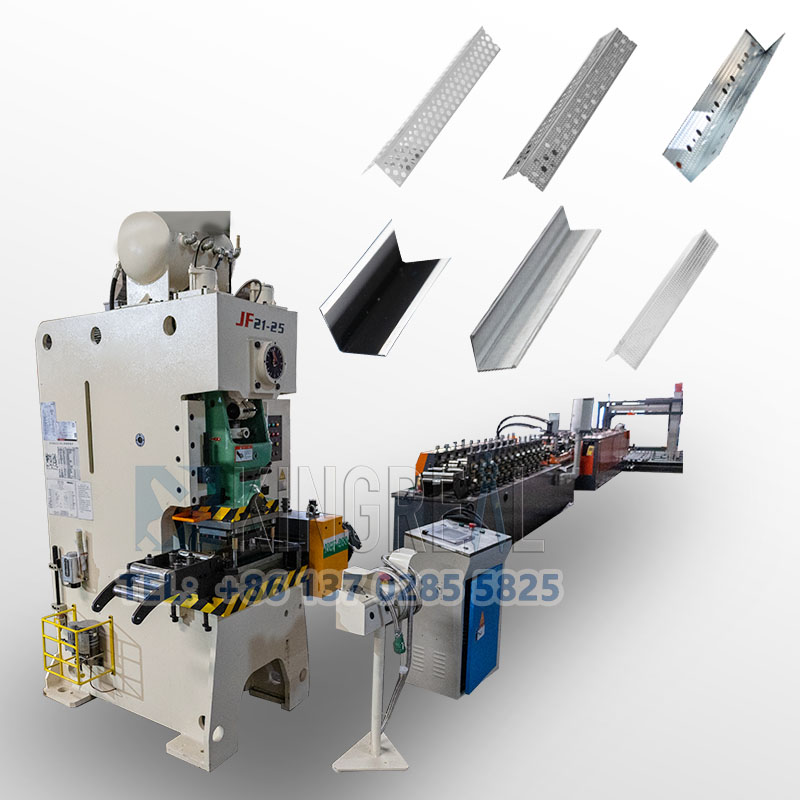

The quality of the false ceiling channel machine is the basis for ensuring its long-term stable operation. From the initial design to the finished product delivery, each link determines its future service life and performance.

(1) Selection of high-quality materials

KINGREAL CEILING MACHINERY is well aware of the importance of materials, so it is extremely strict in the selection of raw materials. All materials entering the factory must undergo strict quality inspections, and any raw materials that do not meet the standards will be returned to the supplier to ensure the stability and durability of the product. High-quality steel and high-strength alloy components can effectively resist wear, corrosion and fatigue during long-term operation.

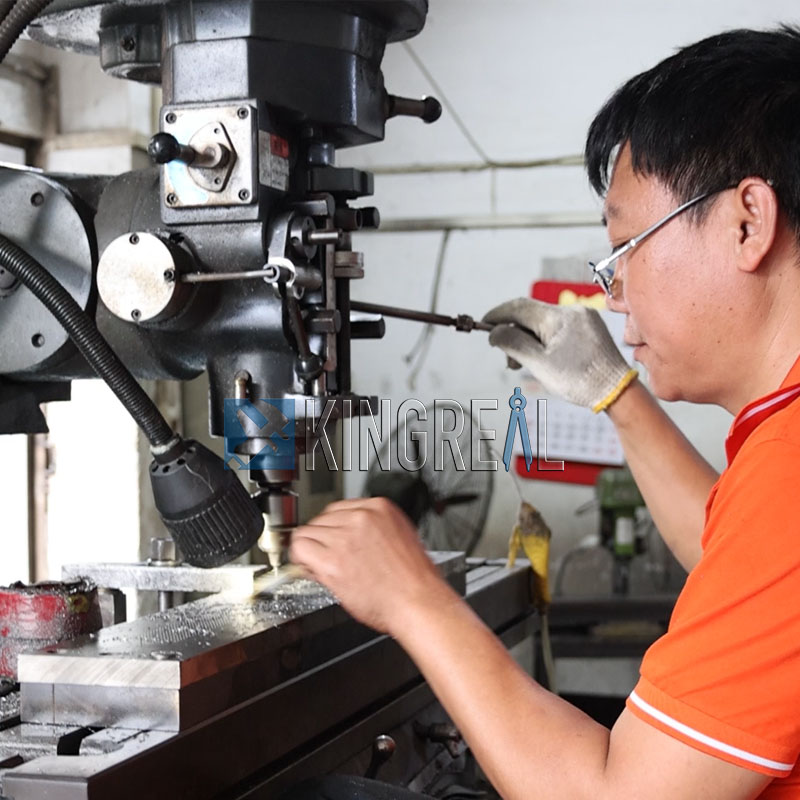

(2) Exquisite manufacturing process

During the L-shape profile machine manufacturing process, KINGREAL workers always adhere to the spirit of craftsmanship of striving for excellence. From the processing of parts to the assembly of the whole machine, each step is precisely measured and strictly controlled. Even the smallest screw is required to be perfectly matched with the machine to ensure the stability and reliability of the equipment under high-intensity work. Advanced CNC numerical control equipment, laser cutting technology and automated welding technology make the u channel roll forming machine's precision and strength reach the industry-leading level.

Correct use method: professional training and standardized operation

Even if the false ceiling channel machine itself is of high quality, if it is used improperly, its service life will be greatly shortened. Correct operating habits and standardized work processes are one of the keys to extending the life of the L-shape profile machine.

(1) Professional operation training

KINGREAL CEILING MACHINERY provides professional engineer training services for each customer to ensure that the operator can fully understand the working principle, operation steps and safety precautions of the L-shape profile machine. Engineers will go to the customer's factory to demonstrate the correct startup, operation, debugging and shutdown processes to help workers master efficient and safe operation skills.

(2) Precautions during use

- Avoid overload operation: The u channel roll forming machine is designed with its rated load. Long-term overload operation will accelerate component aging and even cause failure.

- Maintain stable voltage: Unstable power supply will affect the normal operation of the control system and motor, and voltage stabilization equipment is required.

- Prevent foreign matter from entering: The working environment should be kept clean to prevent dust, metal debris and other debris from entering the machine, causing jamming or damage.

- Correctly adjust the mold: Improper mold adjustment will cause additional pressure on the machine and shorten the life of the mold and equipment.

Regular maintenance: Systematic maintenance and inspection mechanism

Regular maintenance is an indispensable part of extending the life of the omega channel machine. Through a scientific maintenance plan, potential hidden dangers can be discovered in time to prevent small faults from developing into big problems.

(1) Daily maintenance

- Lubrication system maintenance: Regularly check and add lubricating oil to keep gears, chains, bearings and other components in good lubrication status to reduce friction and wear.

- Cleaning work: Clean the equipment surface and key components after work every day to prevent dust and metal chips from accumulating.

- Tightening inspection: Regularly check whether the screws and fasteners are loose, tighten them in time to ensure the stability of the equipment.

(2) Periodic maintenance

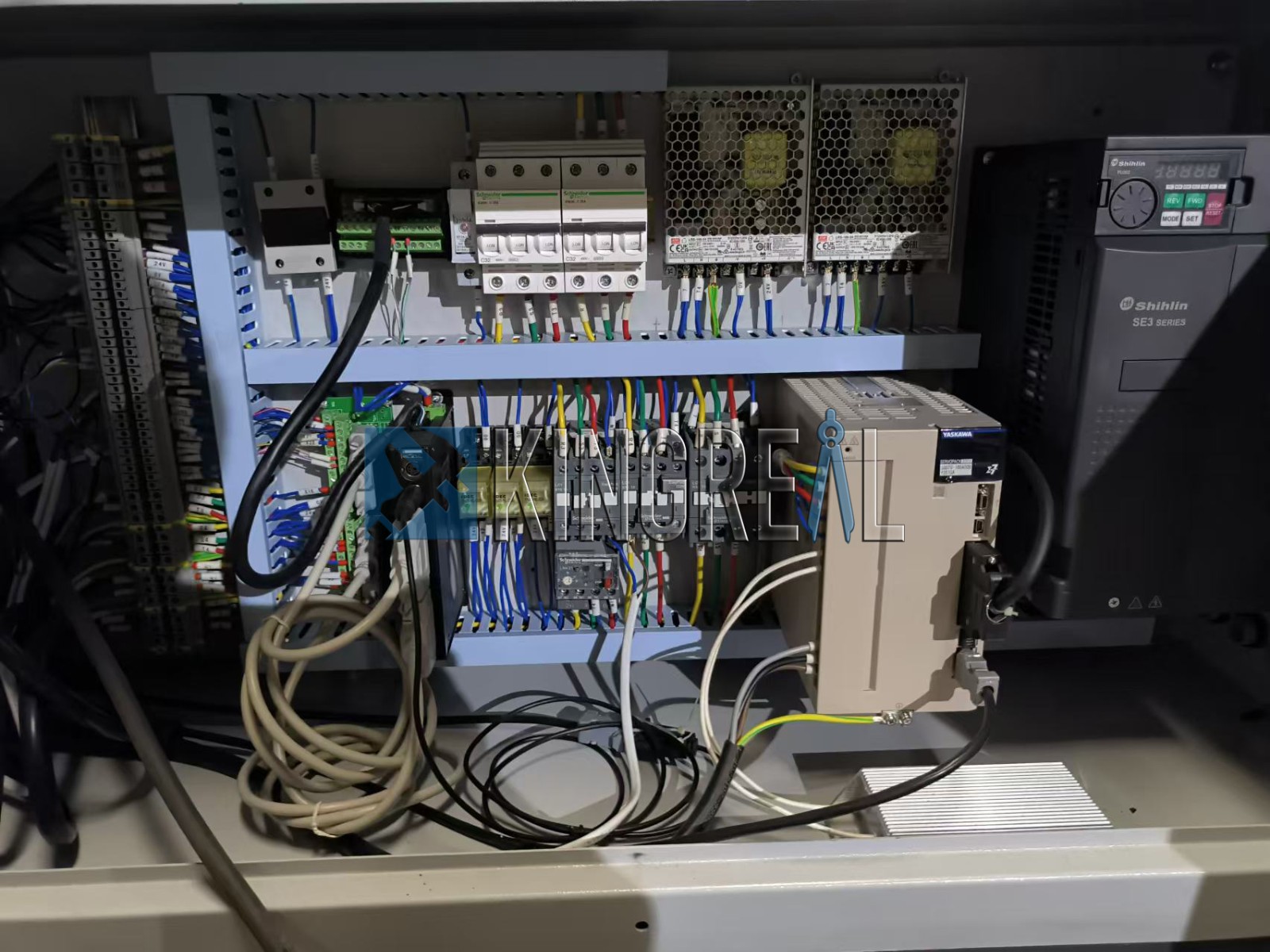

- Electrical system inspection: Check whether the electric control box, cables, and terminals are aging or loose to ensure the safety of the circuit.

- Hydraulic system maintenance: If the u channel roll forming machine is equipped with a hydraulic system, the hydraulic oil needs to be replaced regularly and the oil pipes need to be checked for leakage or aging.

- Mold and tool maintenance: Regularly check the wear of molds and tools, and repair or replace them in time to maintain good cutting accuracy.

(3) Fault warning and emergency handling

Equipped with necessary monitoring and alarm systems, such as temperature sensors, pressure sensors, etc., to monitor the operating status of the equipment in real time. Once an abnormality occurs, the operator can take quick measures to avoid the expansion of the fault.

Get the latest price? We'll respond as soon as possible(within 12 hours)